Multi-Discipline Engineering

Holistic, Comprehensive Solutions for Multidiscipline Engineering

Boost User Productivity for All Disciplines

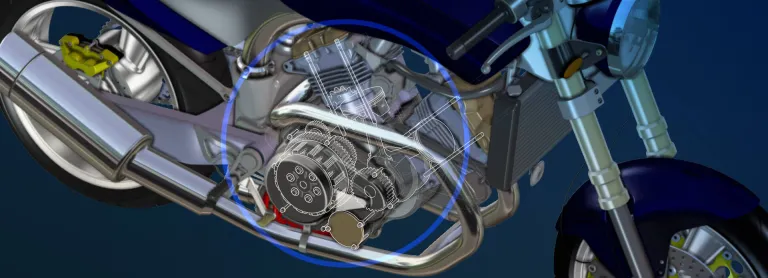

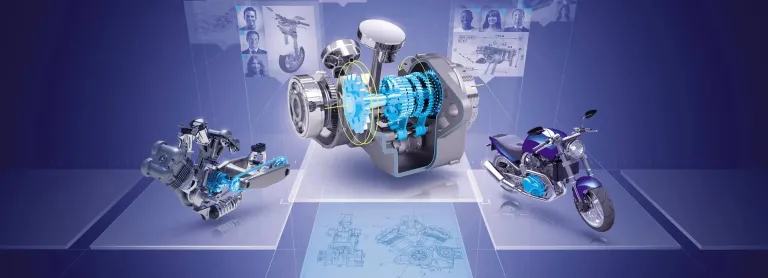

Sustainable and digital transformations are at the heart of the market’s expectations, as well as innovations in many new technologies. This complexity must be handled carefully with traceability to satisfy safety, regulation compliancy and reliability. The answer is a unique multi-discipline, multi-CAD digital mock-up enabling mechanical, electrical, fluidic and simulation engineers to collaborate on a single source of truth.

With Dassault Systèmes’ 3DEXPERIENCE platform, our customers are experiencing true digital continuity with a single source of truth and real-time collaboration. This allows them to simplify operations and spend more time on what they do best: develop breakthrough technologies for unprecedented innovations, design and manufacture best in class machines.

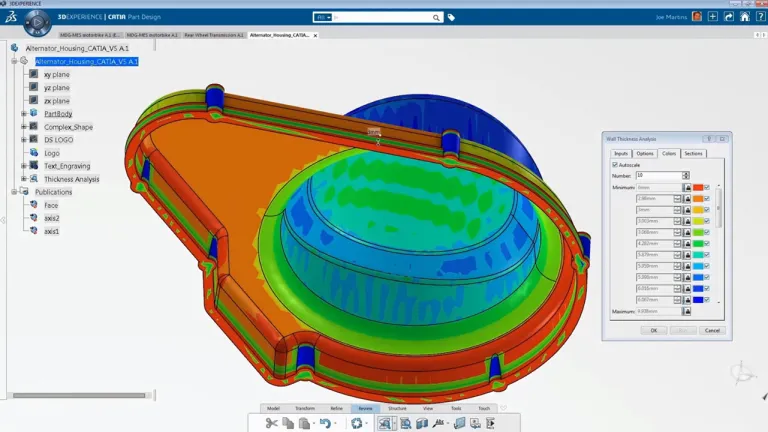

Flexibility Regardless of Production Method

There is a manufacturing talent shortage, and the pandemic made it worse. With this loss of manufacturing knowledge, engineers need better tools to assess manufacturability.

Whether parts are plastic, composite, or other material, CATIA can handle it. It supports various manufacturing processes, including injection molding, casting, stamping, sheetmetal bending, welding, and 3D printing. Further, cost estimates helps determine the best production method.

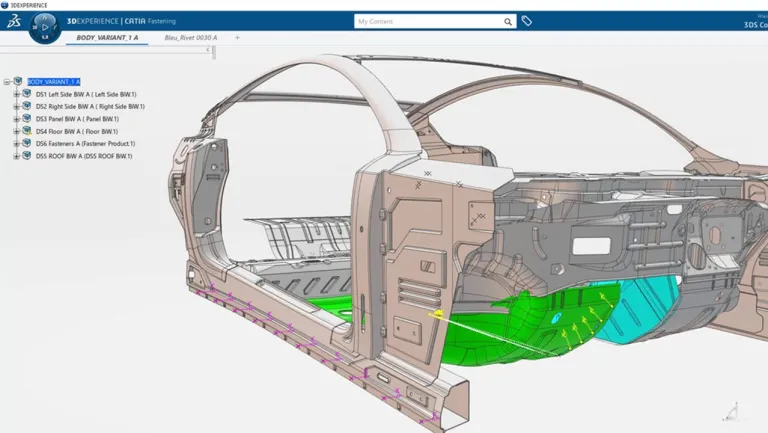

Fasteners Hold Everything Together

Fasteners are an integral part of the product development process. Considering the current market trends with A-VE´s , smart cities etc. the growing complexity of systems in general is directly impacting product development. The traditional way of designing and manufacturing products is not enough to keep up with the market’s fast pace.

The 3DExperience platform offers an end to end connected engineering solution for fastener definition/management, simulation and manufacturing with CATIA 3DExperience Fastening Application (Definition & Management).

CATIA Multi-Discipline Engineering software products are packaged as Roles on the 3DEXPERIENCE platform to get you up to speed faster and work more efficiently with all needed applications available at your fingertips. Select a package that corresponds to your role in an organization.

For us, it was important to find the sweet spot, a good trade-off, between manufacturing effort and the lightweight performance we could achieve. And this is where the integration of our virtual model with the real production process became essential. By using CATIA, we were able to generate all the necessary manufacturing data, from detailed 3D models to precise tooling instructions.

Join the conversation in the CATIA User Community!

FAQ About Connected Engineering

Also Discover

Learn What CATIA Can Do for You

Speak with a CATIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right CATIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering