Fluid Engineering

Design End-to-end, compliant Fluid Systems in a Collaborative Product Development platform

Accelerated Development Fluid Systems with Full Compliance

Fluid systems are designed to process fluids such as piping, tubing, HVAC, transport them, or transmitting power thru fluids in some cases. These systems can be manufactured from different materials depending on applications. As the material & flow properties can vary along the process, design of fluid systems is governed by various standards & specifications. This enables strict codification, classification, compliance in the context of usage.

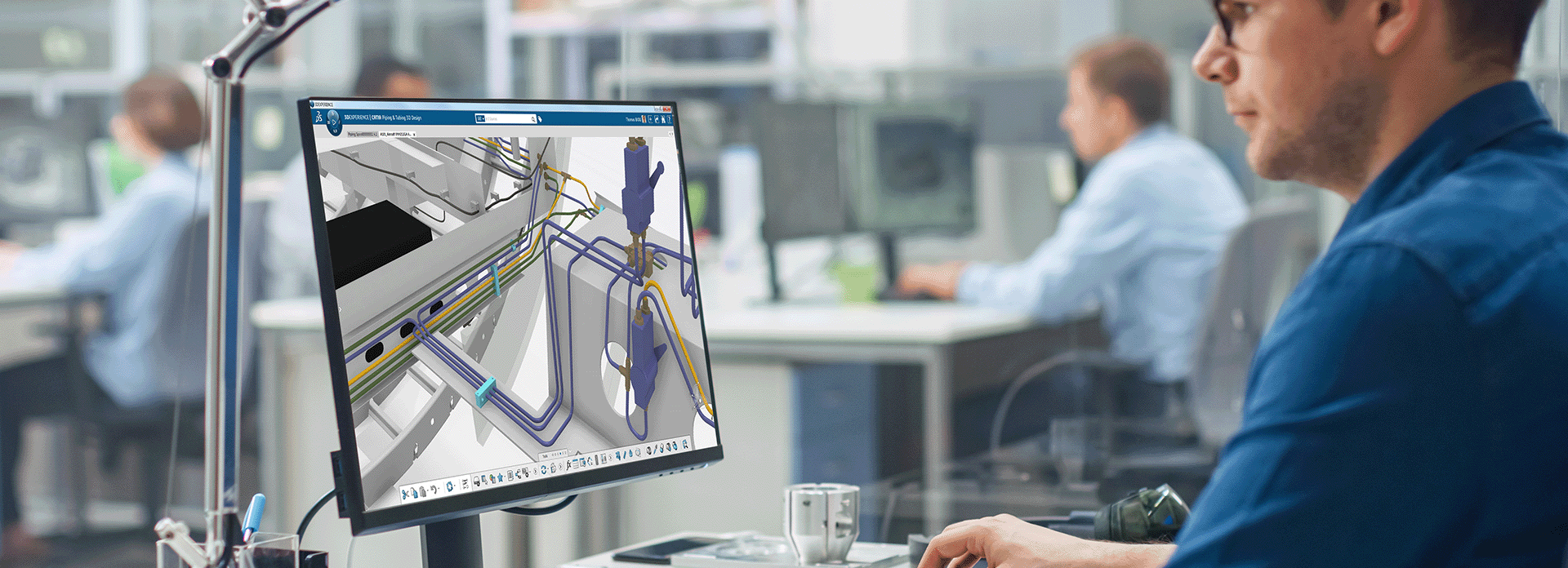

The 3DEXPERIENCE platform enables lifecycle management of piping, tubing and HVAC systems. Quick and easy integration with processes helps accelerate collaborative delivery of product innovations. This also strengthens the ability to manage complex systems.

Solve Complexities with Standardization

Due to the increasing product/process complexities, fluid system makers follow a standardization approach. This ensures not only compliance to the regulations, but also enables engineers to work within narrower options that are already validated.

CATIA 3DEXPERIENCE Fluid Engineering Solutions supports deployment of such standards and specifications (thru Engineering Specifications Editor, Data-Setup apps & libraries/catalogs). Site-administrators can allow engineers of a project to work within a specific set of standards relevant to that industry. Thus ensuring a higher degree of compliance.

Comprehensive End-to-end Collaborative Process

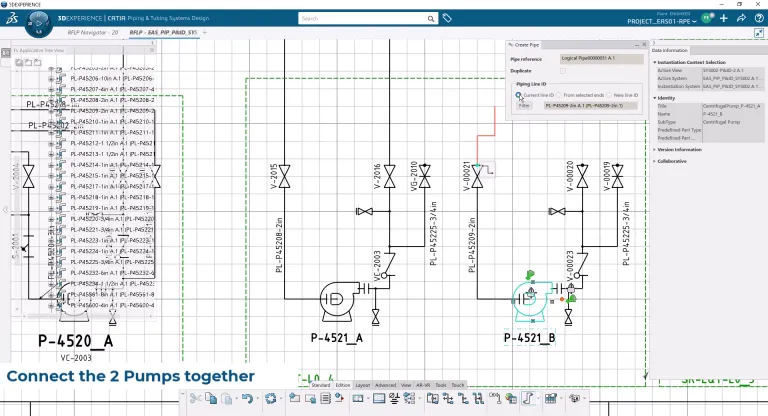

With 2D Schematics, create your diagrams easily and quickly using efficient 2D tools. Be it preliminary block diagrams or advance PFDs or complex P&IDs, schematics tools not only address different levels of complexities, but also multi-disciplinary data-objects.

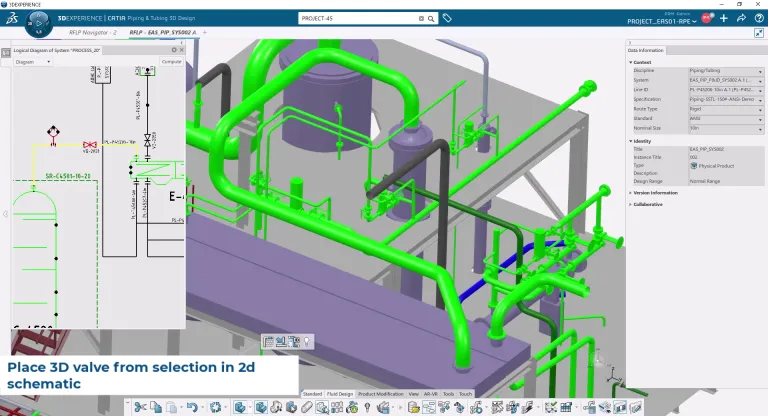

Synchronize 2D Diagrams with 3D Design

3D Fluid Engineers can make an early start, even if schematics are not ready, hence saving time. At an appropriate maturity milestone, the 2D and 3D designs can be synchronized to ensure completeness as well as traceability.

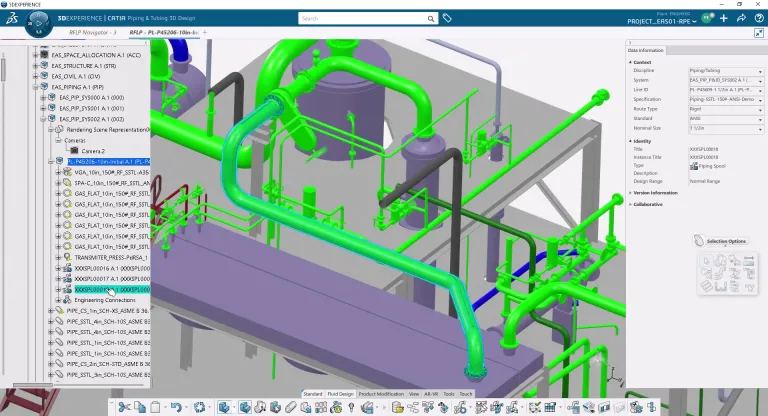

Advance 3D Design capabilities with Automation and Optimization

Fluid 3D Systems design tools help engineers place equipment’s and create the fluid network efficiently. Strong geometrical capabilities along with robust compliance mechanism help achieving their objectives. Additionally, design automation enables higher productivity and less errors.

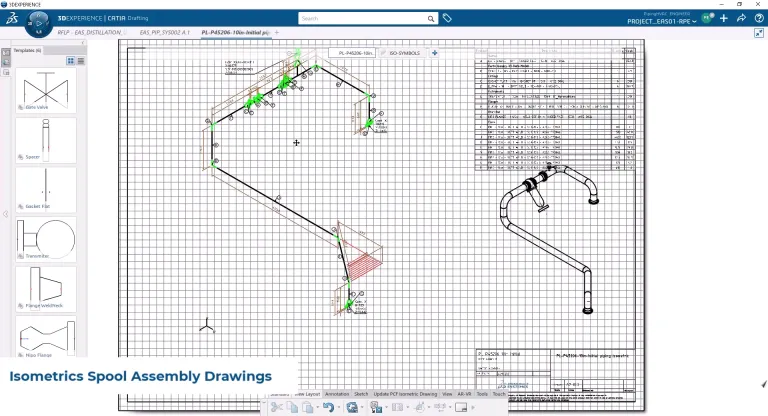

Ready for Manufacturing

Design journey doesn't stop at 3D design, manufacturing deliverables can be easily generated according to specific requirements. These deliverables can be spool fabrication drawings, assembly drawings, engineering BOM, manufacturing BOM, reports, etc.

CATIA Fluid Engineering software products are packaged as Roles on the 3DEXPERIENCE platform to get you up to speed faster and work more efficiently with all needed applications available at your fingertips. Select a package that corresponds to your role in an organization.

Join the conversation in the CATIA MBSE Cyber System User Community!

Also Discover

Learn What CATIA Can Do for You

Speak with a CATIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right CATIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering