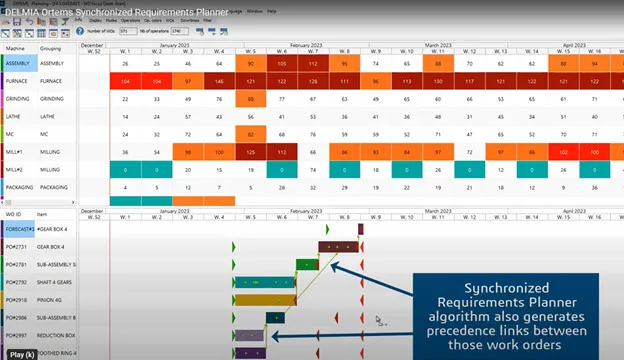

Synchronized Requirements Planner

Enhance Lead-time Reliability with Multi-level Bills-of-Materials Synchronization

Optimize Inventory Planning & Accelerate Production Flow

DELMIA Ortems Synchronized Requirements Planner provides the material flow and capacity synchronization system that enables Just-in-Time (JIT) demand and manufacturing integration across all Bill of Materials (BOM) levels, helping to optimize inventory planning and manufacturing capacity. Synchronized Requirements Planner uses a multi-level BOM approach to accelerate flow lines by synchronizing both purchase and work orders from raw materials to semi-finished to finished products—placing constraints related to inventory and available raw materials on the schedule. It goes beyond typical material requirements planning by creating pegging links between semi-finished and finished product work orders, working with DELMIA Ortems Production Scheduler and DELMIA Ortems Manufacturing Planner to balance loads and accelerate flow lines.

Key Benefits:

-

Reduces buffer inventory

-

Synchronizes multi-level BOM

-

Analyzes impact across manufacturing

-

Instills dynamic customer-to-supplier traceability

-

Improves customer service and lead-time reliability

-

Synchronizes materials and works

The major benefit of DELMIA Ortems is being able to cross-reference our data with our current ERP. DELMIA Ortems lets us provide reliable lead times to our end customers and sales representatives who are deployed in the field.

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering