DELMIA Apriso

Transform Global Production Operations

What is DELMIA Apriso?

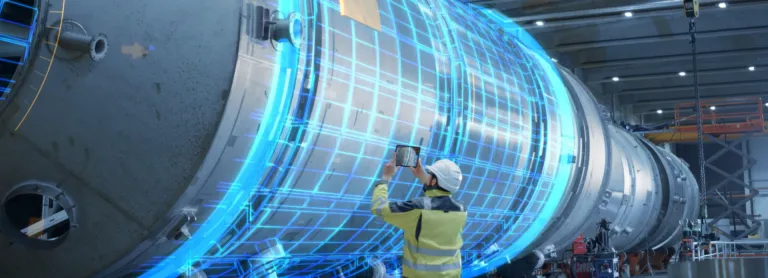

DELMIA Apriso is a cutting-edge MOM software. It helps manufacturers to transform global production operations. As a Manufacturing Operations Management (MOM) software and Manufacturing Execution System (MES) software, DELMIA Apriso has been recognized by industry analysts, including ABI, Gartner, and IDC. DELMIA is the proven solution with applications specifically developed for managing the complete business process lifecycle and consistent development of global processes and best practices around the world. DELMIA Apriso creates a foundation for digital transformation that is unified, flexible, scalable, secure and provides real-time availability to critical manufacturing data for responsive decision-making. With the Virtual Twin Experience, DELMIA goes beyond the digital thread by connecting the virtual and real worlds of manufacturing with the broader supply chain. By having a real-world, model-based representation of the manufacturing network: plants, lines and work cells capturing all manufacturing data, combined with the virtual model of the process and product, DELMIA ensures a single source of truth for bringing products to market.

Now enhanced by DELMIA Augmented Experience augmented reality solutions, users can leverage technologies like interactive 3D, augmented reality, computer vision, AI and deep learning to guide human operators in complex assembly tasks and automate quality inspections based on the product virtual twin. Produce right the first time to drive significant time and cost savings. DELMIA Apriso encapsulates all the core functionality required in a traditional MES, in addition to the expanded MOM capabilities including integrated quality, material synchronization, and maintenance. Manufacturers can gain real-time, data-driven KPIs to measure productivity, better manage production lines, material flow and cycle times, enhance entire production systems and drive real-time manufacturing processes. In addition, DELMIA provides broad industry and manufacturing model coverage, supporting 9 industries with varied manufacturing models—from BTO, ETO and project/program based, to BTS, repetitive, batch, process and hybrid manufacturing—and can be globally deployed across a vertically integrated enterprise or a diversified global manufacturer.

Benefits of DELMIA Apriso

Operational Efficiency

Streamline your manufacturing processes for increased efficiency and reduced downtime.

Compliance Assurance

Meet industry standards and regulatory requirements with robust traceability and quality management features.

Data-Driven Decision Making

Leverage real-time analytics to make informed decisions that drive continuous improvement.

Key Features of DELMIA Apriso

- Manufacturing Operations Management (MOM) / Manufacturing Execution System (MES)

DELMIA Manufacturing Operations Management solution helps in tracking and managing the production process in real-time. It includes functions such as production scheduling, resource allocation, and quality management. - Business Process Management

The software enables enterprise-wide standardization of a Manufacturing Execution System (MES), centrally monitored and updated for all plants. - Equipment Maintenance & Management

DELMIA Apriso Maintenance coordinates with other applications to efficiently manage maintenance, minimizing disruptions and maximizing uptime for your manufacturing environment and team. - Production Monitoring and Analytics

DELMIA Apriso Analytics & Reporting provides real-time visibility into production performance, allowing for analysis and optimization of manufacturing operations. - Manufacturing Production

DELMIA Apriso ensures manufacturing excellence by extending visibility beyond facility walls to the entire product supply network. - Quality Control & Management

DELMIA Apriso allows for the monitoring and control of product quality throughout the manufacturing process, including inspections and audits. - Integration with ERP Systems

DELMIA Apriso System Integration can seamlessly integrate with enterprise resource planning (ERP) systems to ensure seamless communication and data exchange between manufacturing operations and other business functions. - Time & Labor Planning

DELMIA Apriso solutions support manufacturing excellence by tightly linking labor tracking to plant activities. - Synchronized inventory management

DELMIA Apriso Warehouse surpasses traditional systems by unifying inventory and production management, leading to significantly improved accuracy and manufacturing efficiency.

DELMIA Apriso Solutions

The quality advantage (with ACE) is we have better access to traceability data and batch tracing at the line. A big advantage of this ACE project for the plant is we have integrated, real-time information flow. Reaction time has been cut short very much. Data transference is much better than we had before.

Start Your Journey

Useful Resources

FAQs

DELMIA Apriso provides all the core functionality required in a traditional MES, including production tracking, work instructions, and machine connections, for example. MOM includes MES and its capabilities, but also all other activities that support production.

Got more questions? Check our FAQ page and find the answer you're looking for!

DELMIA Apriso focuses on larger enterprises, while DELMIAWorks combines ERP and MES capabilities in a solution built for small and midsize businesses (SMBs).

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering