Metals & Alloys

Supporting Metal Alloy Design with BIOVIA Materials Studio

In Silico Metal & Alloy Design

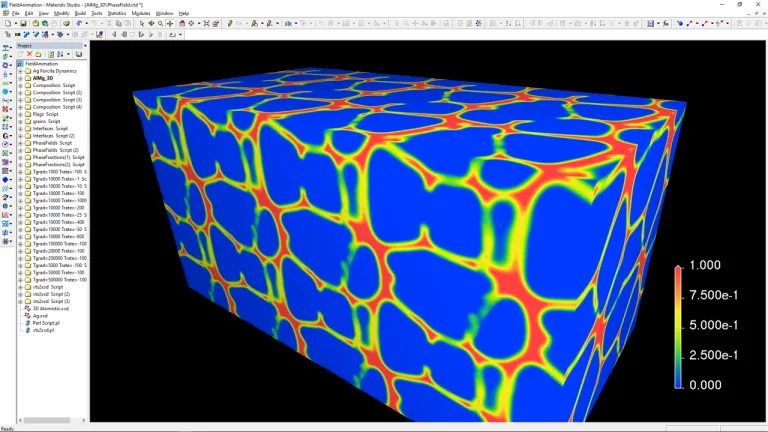

Pure metals are generally too soft for demanding industrial applications. They may instead be combined with other metals to create more durable alloy compounds. Materials Studio can be used to design new alloys in silico to meet specific performance criteria and to predict their highly complex phase behavior. This is of particular importance when designing new materials for use in additive manufacturing. The microstructure formed during the solidification process in the flat bed sintering is very sensitive to the specific conditions of the powder bed. The microstructure in turn has a strong influence on the performance of the printed part. In silico methods allow researchers to explore the enormous chemical space to identify novel high-performance alloys and understand the performance of existing ones.

A Powerful Combination

BIOVIA Materials Studio in combination with BIOVIA Pipeline Pilot provides a variety of methods to identify stable multicomponent alloy compositions and predict their corresponding material properties.

- Fit CALPHAD databases and produce:

- Phase diagrams

- Solidification using phase field simulations

- Calculate properties needed by SIMULIA and other Dassault Systèmes tools to run simulations such as homogenization of Representative Volume Element (RVE) models

- Alloys

- Additive Manufacturing

Alloys

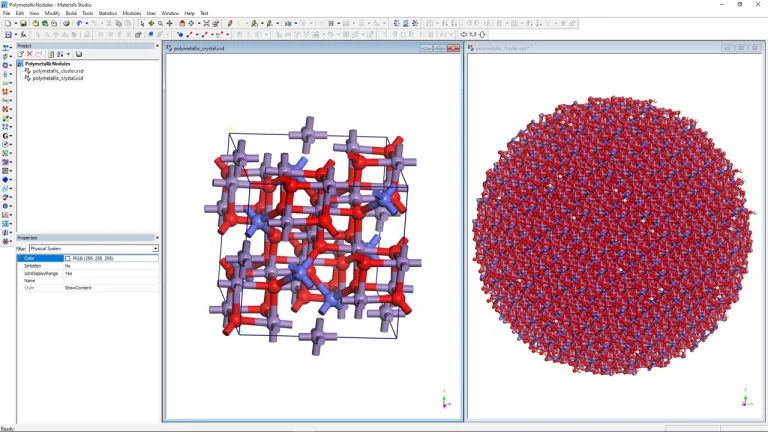

- Propose stable lattice structures for multicomponent alloys based on their composition

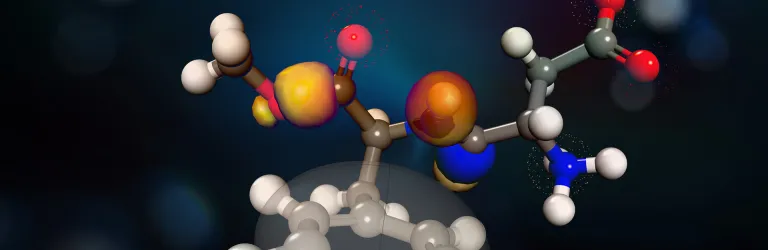

- Calculate material properties for the alloys based in quantum mechanical methods in CASTEP, such as mechanical and elastic properties; elastic coefficients, elastic moduli; thermal properties, thermal conductivity, thermal expansion, heat capacity; electrical properties, magnetic moment

- Assess the molecular interactions between alloy surfaces and coatings

- Construct cluster expansions for multicomponent alloys and calculate properties to screen a large variety of alloy configurations

Additive Manufacturing

- Predict energetic favorability of disordered alloy formation based on composition

- Determine thermal conductivity and thermal expansion, which may be used to understand the material behavior during selective laser melting and subsequent cooling process to assess material usability for additive manufacturing

Explore Our Methods

The world of Metals & Alloys is changing. Discover how to stay a step ahead with BIOVIA

Join the conversation in the BIOVIA Materials Studio User Community!

Also Discover

Learn What BIOVIA Can Do for You

Speak with a BIOVIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right BIOVIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering