Changing Relationships With Customers

The pressures of digitalization and the global pandemic have transformed the global consumer at all scales, and businesses are learning how to adapt.

How are customer dynamics changing, and how can you accommodate them?

What’s happening?

The customer is king, but there’s been a regime change. A new generation of shoppers expect more – more personalization, more options, more connected services, and more unique experiences. Manufacturing industries are trying to get a sense of the lay of the land and work out how to make their products meet the rapidly evolving expectations of the new customer relationship.

The biggest driver in reshaping the retail landscape has of course been the inexorable march towards online shopping. Research from Morgan Stanley indicates that online sales now stand at 22% of all sales, up from 15% in 2019.

“The biggest change that we've seen is the rise of distance selling,” says Tom Acland, CEO at 3DEXCITE®, Dassault Systèmes. “That was obviously something that was going on before, but it has been accelerated through the experience of the last two-and-a-half years.”

Curious about how other manufacturing industries respond?

Respond to today's challenges with our bespoke solutions

Why does it matter?

The rapid rise of online retail has specific consequences for manufacturing industries, changing the way they make, market, and sell their products. For instance, the rise of distance selling, over digital channels, changes the way product information needs to be presented, and how customer data needs to be handled.

“Historically, selling processes for industrial retail might have been quite high touch,” says Acland. “Buyers may have done site visits. They may have done product research based on paper formats or 2D schematics. Virtual selling changes that landscape.”

Growing digitalization has also ushered in the rise of servitization as a business model. The customer-product relationship is going beyond the point of sale and focusing far more on aftermarket services.

On top of this, the rise of sophisticated agile factories, is also ushering new generations of personalized products, including the rise of mass customization and mass personalization. In this post-COVID world of digital-first customer relationships, how do manufacturers meet these ever-growing demands?

How can I prepare?

In an increasingly virtual retail environment, digital solutions that can create a more immersive relationship between seller, buyer, and product are critical – providing a shared digital thread that connects product design to feedback, and enables continuous iteration and customer service.

Emerging technology is accelerating this shift, none more so than immersive virtuality (IV). Ranging from augmented to virtual reality, IV is bringing new levels of immediacy, realism, and personalization to online retail, both for the B2C and B2B sectors.

For example, in the industrial equipment sector, most line builders still explain their product with 2D drawings or on a real machine. This won’t show the bespoke production line that the customer is requesting. Through immersive reality, line builders can help their customers envision how the equipment, or particular, personalized products, could be configured to seamlessly fit into their production process.

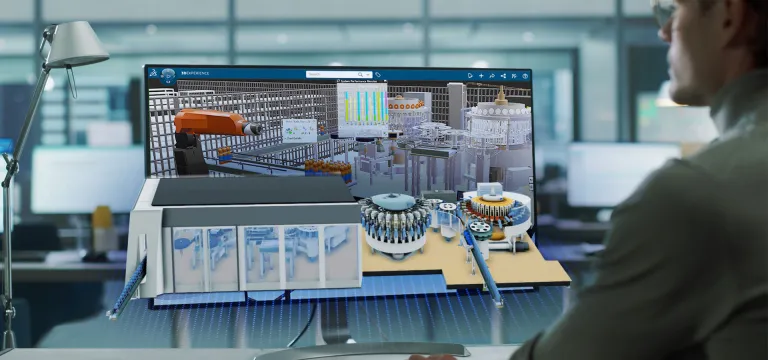

“If you’re buying equipment for a factory, you're looking at obviously sophisticated systems,” says Acland. “All of that knowledge about the product, and what it's going to do in certain circumstances you want to test for, can get very complex.”

The rise of virtuality is enabling sellers to provide more tailored online sales experiences. For instance, by using a virtual twin for commerce, sales and marketing materials can be focused for a particular client. Sellers can highlight key information in a customer support context, whether it’s how a cupboard will fit in a new kitchen, or how a gearbox will integrate with a new car design.

As Acland points out: “Whatever the use case, virtual twins allow the seller and the customer to model how a product will perform, with close attention to technical considerations. It lets us carry out really immersive engagement, at scale and at distance.”

If you’re buying equipment for a factory, you're looking at obviously sophisticated systems. All of that knowledge about the product, and what it's going to do in certain circumstances you want to test for, can get very complex.

Other Trends

Discover more with our Manufacturing Industries

- Aerospace & Defense

- Consumer Packaged Goods & Retail

- Home & Lifestyle

- High-Tech

- Industrial Equipment

- Marine & Offshore

- Transportation & Mobility

THE WORLD NEEDS MANUFACTURERS

A MANIFESTO FOR CHANGE