TASECS

Seeking for a single, integrated solution that could offer PLM capabilities and a single source of truth to advance its transition towards platform-based design, TASECS implemented the 3DEXPERIENCE platform and standardized the flow of information across its business. Tailored for aerospace and defense suppliers, the company used the Engineered to Fly industry solution to enhance its productivity, from bid to delivery. This has resulted in a 30% time saving compared to previous way of working.

Engineering environmental control systems for safe flights

Aircraft are exposed to the most extreme of temperatures. While on the ground, they can face highs of 43°C; minutes later, they could be cruising through -54°C at 35,000 feet – a height at which air pressure lowers to a point that no human could survive for more than a couple of seconds.

As passengers, we are often oblivious to these temperature fluctuations and variations in air pressure and quality. That’s because environmental control systems (ECSs) regulate the onboard environment to keep us safe and comfortable.

One company committed to developing these vital, yet often complex, systems is Turkish Aerospace Environmental Control Systems (TASECS), established in 2019 as a sub-entity of Turkish Aerospace (TA), which plays a crucial role in the Turkish aviation industry.

TASECS designs, engineers and tests ECSs, as well as automated climate systems and air conditioning units for aircraft. While its main client is TA, it also supplies other major aeronautics companies across the globe.

Today, TASECS manages all these projects using ENOVIA on Dassault Systèmes’ 3DEXPERIENCE platform. But it wasn’t always this way.

Together with infoTRON, we found solutions to our challenges that were leading to critical issues. Now, with the 3DEXPERIENCE platform as our PLM, we have far better alignment between departments, with an easy and secure data flow. As a result, we can now quickly handle changes to our projects, and better position ourselves to grow.

Challenge

In the past, TASECS handled all the data related to its vast library of complex systems using spreadsheets. CATIA V5 designs and associated information were stored locally and communication between team members was either verbal or via e-mail.

Without a central source of information, engineers found it difficult to source the latest project information, and duplication was rife. At the same time, without a systematic way of tracking adjustments to a design, effective change and issue management was almost impossible.

TASECS sought a single, integrated solution that could offer PLM capabilities and facilitate its transition towards platform-based design – an approach to developing complex products that favors the systematic reuse of parts.

Solution

As the TASECS team began the search for a solution, colleagues at TA recommended to contact infoTRON, a local technology provider that TA had successfully worked with to help it leverage additive manufacturing.

infoTRON recommended to transition to Dassault Systèmes’ 3DEXPERIENCE platform, including ENOVIA for PLM. The Dassault Systèmes business partner demonstrated the platform’s core competencies and spent significant time walking TASECS through the implementation process.

TASECS was immediately taken with infoTRON’s vision and support. It was impressed with the 3DEXPERIENCE platform’s user-friendly interface. Recognizing that 80% of its industry peers use Dassault Systèmes’ products, felt the solution would help it fully integrate with the local ecosystem.

With the solution partner and platform selected, deployment began. TASECS set up a PLM implementation task force comprising users from every department to ensure buy-in at every level. Working together with infoTRON to establish the right infrastructure, determine workflows, manage configuration and apply appropriate training, the company validated the solution in a test environment before rolling out the integrated ecosystem to everyone in the business.

Benefits

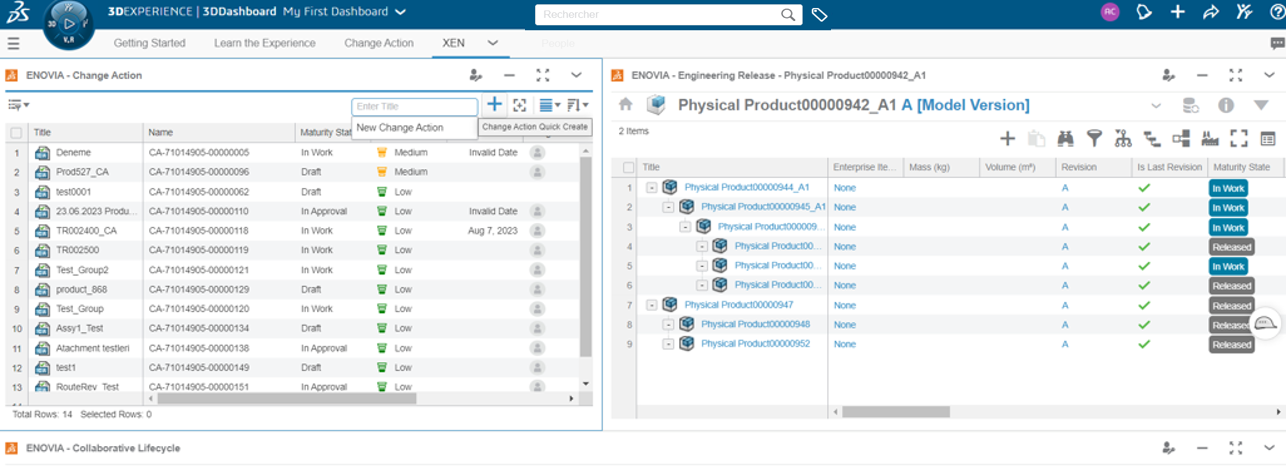

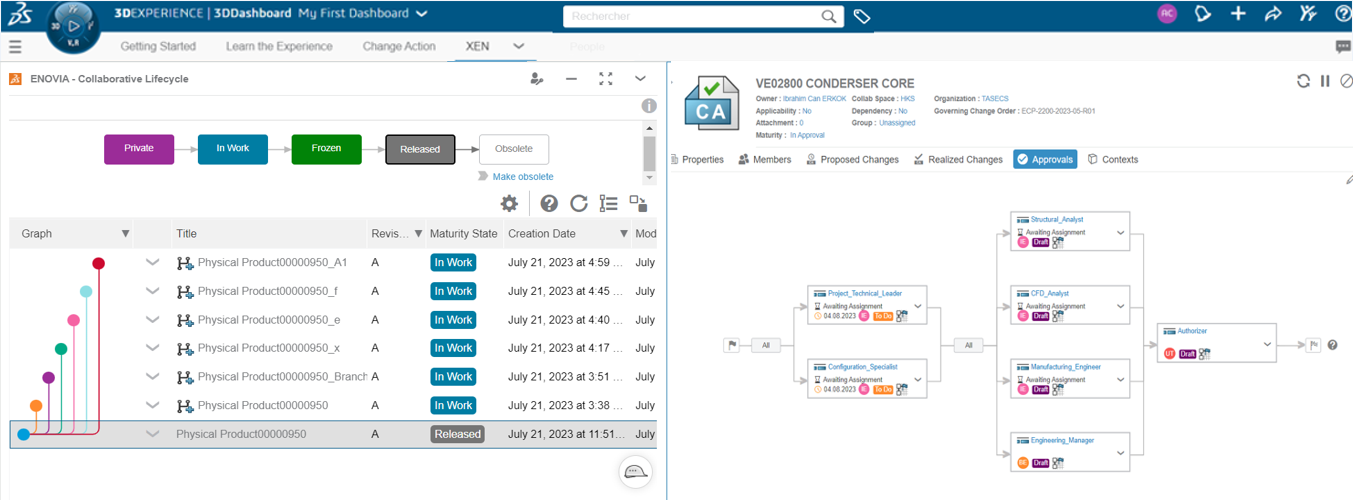

By adopting ENOVIA on the 3DEXPERIENCE platform, TASECS now has a leading-edge PLM environment that has standardized the flow of information across the business and beyond. Administrators can manage users and assign roles within the solution, enabling employees to access and collaborate on the same data.

Using POWER’BY, TASECS can leverage its existing CATIA V5 data in the 3DEXPERIENCE platform. This, along with the CAD data of components provided by third-party suppliers, can be combined into a single assembly model of a complete part or project.

The CATIA V5 models inform an engineering bill of materials (eBOM) that provides a comprehensive representation of a product or project’s design structure. This improves alignment between TASECS’ various departments, provides more accurate cost estimates, facilitates efficient production planning and supports regulatory compliance.

Integrated change management processes mean that any modifications to a part or project are systematically tracked in the eBOM. This enables TASECS to monitor the effect of changes at a project, platform and aircraft level and has resulted in a 30% time saving compared to the previous way of working.

TASECS has now made a determined move towards platform-based design, since it has a library of systems and components that can be reused in new projects. This reduces development risks, costs and time to market.

To leverage a digital twin, the company is evaluating migration from CATIA V5 to CATIA on the 3DEXPERIENCE platform so that models and data can be created in the PLM environment.

Discover more about the Engineered to Fly industry solution experience.

Focus on TASECS

TASECS was established in 2019 as a 100% subsidiary of Turkish aerospace leader TAI. The company develops bespoke environmental control systems, air conditioning solutions and cabin pressure capabilities according to the technical specifications of each flying platform. With its versatile engineering capabilities, expert personnel and technological competence, TASECS aims to develop local capabilities and end external dependency in this field.

For more information: https://www.tasecs.com.tr/en

Focus on infoTRON

Founded in Turkey in 1994, infoTRON is one of the largest providers of technology solutions and services, and a certified Dassault Systèmes Gold partner. With its vast industrial knowledge and innovative approach, infoTRON provides the latest technology products and solutions to its customers for the most effective business results. It provides added value to stakeholders, customers and the society through technologies that enable sustainable growth and 3D innovation and is an industry initiator when it comes to additive manufacturing.