Premekon

The Finnish company uses the Digital Equipment Continuity industry solution to design and manufacture steel structures and service platforms while improving data management and collaboration.

Industrial turnkey solutions for manufacturing plants

Large-scale manufacturing plants often comprise a wide range of complex machinery that makes up a multitude of production lines. Optimizing access to this equipment through carefully thought-out service platforms is essential – and, according to Finland-based company Premekon, can significantly impact a plant’s productivity and output.

As a turnkey solution provider, Premekon specializes in manufacturing these industrial service platforms, as well as other steel structures like stair towers and roof frames. Its customers include leading industrial companies and equipment manufacturers across the globe.

“Complex machinery such as board-making equipment cannot be handed over to the customer without safe, high-quality service platform structures,” said Jussi Tiippana, Premekon’s CEO. “But not all providers of these service platforms are equal. What makes Premekon unique is that we are focused on providing turnkey solutions. We want to offer more value to customers by optimizing the construction of our service platforms to best meet their needs and making the best use of their space so that they can work far more efficiently.”

With manufacturing and design all under one roof, Premekon can offer its customers – who traditionally have to deal with separate companies for the design, manufacturing and assembly of their service platforms – an end-to-end solution, from initial 3D design to on-site assembly.

“We make things a lot simpler, easier and more cost-effective for our customers,” said Leevi Paajanen, Premekon’s design manager. “We optimize design to be as safe and user-friendly as possible while ensuring energy efficiency and lightweight construction. We manufacture in-house and we also offer an installation service. Ultimately, we offer a complete service package to customers, giving them complete peace of mind. They can really trust that we take care of them with our end-to-end solution.”

Premekon does all this while meeting rigorous safety and regulatory requirements, including the EN 14122 series of European standards that ensure safe access to machinery. As the business sought to expand into new markets, it turned to Dassault Systèmes for design and product data management solutions that would provide a powerful and efficient platform for growth.

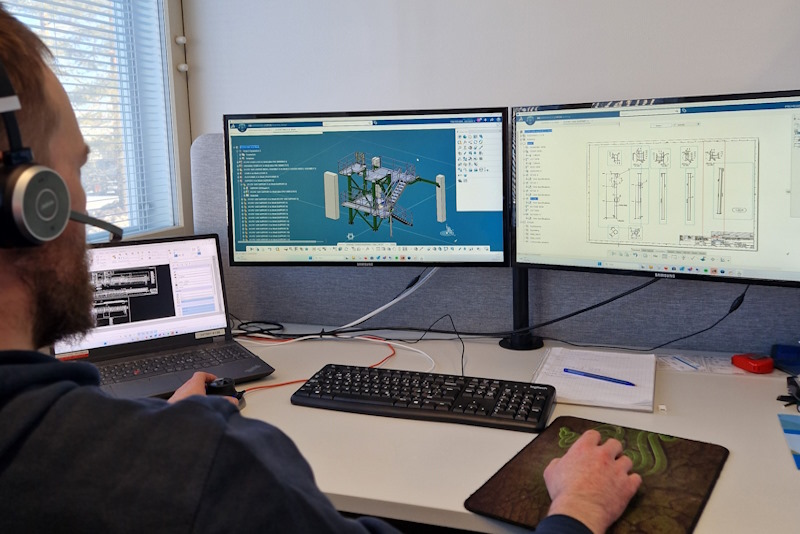

Premekon uses CATIA on the 3DEXPERIENCE platform to create parametric models for each of its products, helping to create even better engineering designs for customers.

The need for precision and efficiency

80% of Premekon’s business has historically come from the paper processing industry, and now Dassault Systèmes tools are helping the company serve customers in new markets such as green energy.

“We see green energy as our next growth area where our end-to-end turnkey service package provides significant value to customers and allows us to differentiate from other players on the market,” Tiippana said. “Our commitment to safety and design capabilities, in addition to our capability to install solutions on site, makes buying from us easy and straightforward for customers.”

At the same time, Premekon must ensure its solutions are optimized for sustainability. “Around 40% of our customers request to see information about our carbon footprint,” Paajanen said. “Over 90% of our carbon footprint comes from the materials we use, so we need to do everything we can to reduce waste and optimize resources. Again, this requires a more effective design process.”

Premekon decided that upgrading its existing CATIA V5 design solution to the 3DEXPERIENCE platform would provide it with expanded design functionality as well as additional capabilities from ENOVIA to improve collaboration, product data management and more.

“We have been a Dassault Systèmes customer for a long time,” Paajanen said. “Not only that, but our biggest customers also use its solutions, so we have already seen the value of collaborating with them using the same design files. By upgrading to Dassault Systèmes’ 3DEXPERIENCE platform, we knew we could build on this functionality and further improve the way we work together.”

Following a straightforward implementation with help from local partner TECHNIA, Premekon was able to get up and running on the latest version of CATIA with just three days of training.

“Everything went very smoothly,” said Joonas Kontkanen, a design engineer and CATIA administrator at Premekon. “Because we were existing CATIA V5 users, the new solution felt intuitive. TECHNIA was on hand to quickly answer our questions.”

Dassault Systèmes solutions allow us to build even more environmentally effective systems. This allows us to further differentiate ourselves and be more customer focused.

Saving time with parametric models

With its new software in place, Premekon has been able to improve every step of the design process. The first step is a consultation with the customer to understand their exact needs. “What we receive from our customers varies considerably,” Paajanen said. “Sometimes they provide us with a 2D drawing. Smaller clients may only give us their hand-drawn ideas.”

Using this information, Premekon will then create a 3D model of their service platform solution to show to the customer. The 3D design considers any plant-specific standards and allows for accurate clash analysis and strength calculations, avoiding the need to make changes to structures in the installation phase.

At this point in the process, CATIA proves particularly useful. “One of the first things we did when we updated to CATIA on the 3DEXPERIENCE platform was to create parametric models for each of our products,” Paajanen said.

Parametric models are digital representations of a product that are constructed via various algorithms and rules that inform its dimensions. This means that, instead of starting each customer’s design from scratch, Paajanen and his team can simply adapt existing models that already comply with the EN 14122 standards.

“Parametric models help us create even better engineering designs for customers,” Paajanen said. “For example, we can take a base model of a service platform, walkway or ladder and extend it easily according to the customer’s requirements.”

Premekon specializes in the production of industrial service platforms and other steel structures, such as stair towers and roof frames. Its clientele includes prominent industrial companies and plant constructors from around the globe.

Better data brings greater accuracy

Since the parametric model captures all information about the product, it can then be used to create a bill of materials (BOM). This precise breakdown of all components, parts and materials required to create a service platform not only enables Premekon to quote more accurately but also facilitates more accurate purchasing of materials and – because it minimizes waste – it helps it achieve its sustainability objectives, too.

“Dassault Systèmes solutions allow us to build even more environmentally effective systems, Paajanen said. “This allows us to further differentiate ourselves and be more customer focused.”

The data from parametric models will also inform the manufacturing process. “The information we give to the manufacturing team is far more detailed than in the past,” Paajanen said. “The manufacturing instructions are clearer and more accurate – making them easier to understand and to review. This means we are less likely to make mistakes in production.”

Everything went very smoothly. Because we were existing CATIA V5 users, the new solution felt intuitive.

Improved collaboration

By leveraging Dassault Systèmes’ latest solutions, Premekon has also improved how it collaborates, both internally and with its customers.

“We can now work directly with our customers within the Dassault Systèmes environment,” Kosonen said. “In the past, we had to navigate a file-based system on a shared server, which often made finding what we were looking for difficult. Now everything is saved on the platform much more logically.”

The use of ENOVIA on the platform has improved internal collaboration, too. “Our various teams can work together and access the same designs at the same time,” Paajanen said. “This makes a huge difference if we are working to strict deadlines – it means we can work much faster than in the past.”

These aren’t the only benefits of working in a centralized common environment. With everyone having a clear view of the latest versions of a design, there’s less chance of mistakes. “It’s no longer possible for designers to accidentally work on old files,” Paajanen said. “Versioning is very clear.”

We see green energy as our next growth area where our end-to-end turnkey service package provides significant value to customers and allows us to differentiate from other players on the market.

A pathway to MODSIM

Premekon is now exploring how it might adopt additional capabilities offered by Dassault Systèmes’ platform. For example, it has seen how it might use SIMULIA to simulate load bearing, usability and the various structural features of its products to further optimize their quality, cost and sustainability performance.

“We’d like to get to a position where we can embrace a unified modeling and simulation (MODSIM) approach that will see design and simulation happen in parallel,” Paajanen said. “We currently create a 3D model and then make a simulation from that. So, each time we must start the simulation from zero. With MODSIM, we will get much quicker results.”

The company is also interested in leveraging DELMIA for manufacturing operations management (MOM) so that it can automate more processes.

“We must constantly find new ways to be competitive, and one way of doing that is increasing the amount of automation and robotics in our manufacturing facility,” Paajanen said. “With DELMIA, we will be able to further enhance the flow of information between design and manufacturing and increase both our capacity for innovation and competitiveness – helping us to enter new markets with ease.”

Discover more about the Digital Equipment Continuity industry solution experience.

Focus on Premekon

Turnkey business Premekon is a privately owned company specializing in design, manufacturing and installation of industrial service platforms. Its customers include several leading industrial companies and equipment manufacturers in Europe, Asia, South America and North America. Premekon currently employs around 100 people and has modern office and production facilities in Joutseno’s industrial area in Lappeenranta, Finland.

For more information: https://premekon.fi/en/

Focus on TECHNIA

TECHNIA is a leading global Dassault Systèmes partner, providing unrivaled customer value with its unique combination of partner solutions, in-house software and expert skills. The company provides complementary software, services, training and support for the complete Dassault Systèmes portfolio of products, including the 3DEXPERIENCE platform, BIOVIA, CATIA, DELMIA, DYMOLA, ENOVIA, NETVIBES, SIMULIA, SOLIDWORKS and more. TECHNIA actively seeks out clients whose leading-edge technologies provide creative solutions to the world’s most pressing concerns. It builds long-lasting relationships with ambitious customers who trust that it is big enough to deliver, yet small enough to care.

For more information: https://TECHNIA.com