CNBM Triumph Robotics

Shanghai-based robotic line builder CNBM Triumph Robotics adopted the 3DEXPERIENCE platform's Digital Equipment Continuity industry solution experience to streamline and standardize its way of working. With virtual commissioning, customers now experience the production lines through virtual twins, which support them with diagnostics, equipment upgrades and training.

Driving advances in robotic automation

In the Songjiang district of Shanghai sits an impressive 18,659 square meter building with a photovoltaic curtain wall that generates an average of 230,000 kilowatt hours of electricity each year. Home to a state-of-the-art research and development (R&D) factory for robotic automation company CNBM Triumph Robotics, it’s the city’s first implementation of building-integrated photovoltaics technology – innovative solar building panels that not only serve as the outer layer of a structure, but also actively generate renewable energy.

Producing the panels of glass that make up a building of this stature is no simple task, especially when done with traditional manual techniques. However, CNBM Triumph Robotics’ intelligent robotic lines enabled its parent company CNBM Group to manufacture the new generation of thin-film solar power generation materials with ease. In fact, thanks to its automated processes, CNBM Triumph Robotics’ glass grading and palletizing system – which it supplies to some of the world’s largest glass factories – enables a sheet of glass to be produced every 3.18 seconds.

To continue to innovate and to stay one step ahead of the competition, CNBM Triumph Robotics – which also provides production lines to cement factories and agricultural firms – is undergoing a digital transformation, with the help of Dassault Systèmes’ 3DEXPERIENCE platform.

The path to digital transformation

CNBM Triumph Robotics turned to Dassault Systèmes at a time when its business was facing a significant number of challenges. “The specifications for glass products were becoming more diverse, as they require thinner dimensions and higher quality. This demanded greater design precision,” said Gao Changqi, CNBM Triumph Robotics’ chief engineer.

At the same time, the business was becoming more complex. Trying to navigate these challenges without appropriate software was not an option. “The number of project teams in the company had grown from two to ten,” said Gao. “As our company grew, our business expanded from single workstations and small-scale integration to entire production lines, conveyor systems and automated guided vehicles (AGVs). We were entering new markets and competition intensified. Managing processes with verbal communication and a file-based system was unsustainable, and we started to see more errors. We needed standardized processes – and fast.”

The 3DEXPERIENCE platform offered a holistic solution, with diverse modules covering all aspects of our digital scenarios. This is very appealing to us.

A solution to improve project management

With several of its sister companies already using Dassault Systèmes’ technology, CNBM Triumph Robotics made the obvious choice of implementing 3DEXPERIENCE platform. CNBM Triumph Robotics decided to utilize ENOVIA for project management, product lifecycle management (PLM) standardization and knowledge banks, and DELMIA for multi-disciplinary collaboration and virtual commissioning.

“We did a thorough review of the market before committing to the software,” Gao said. “The 3DEXPERIENCE platform offered a holistic solution, with diverse modules covering all aspects of our digital scenarios. This is very appealing to us.”

Dassault Systèmes partner DAS Tech assisted CNBM Triumph Robotics in verifying its requirements and resolving legacy data issues. Once the platform was implemented, DAS Tech trained CNBM Triumph Robotics’ engineers on ENOVIA and supported the move to DELMIA.

Now that all processes are managed using ENOVIA, CNBM Triumph Robotics’ associates can plan and design robotic automation projects in their entirety, calculating both cost and risk. Using ENOVIA’s task assignment feature, engineers can see their daily responsibilities and make designs and submissions accordingly. They can also keep track of progress with periodic follow-ups.

“ENOVIA has already significantly improved our project management capabilities,” said Wang Mengran, product manager from CNBM Triumph Robotics’ technology center. “Because all work activities now happen within the platform, everyone is clear on what they are doing so we don’t have to have so many meetings.”

By integrating virtual commissioning capabilities during the equipment production process, CNBM Triumph Robotics is significantly reducing on-site verification time.

A more effective workflow and better BOM management

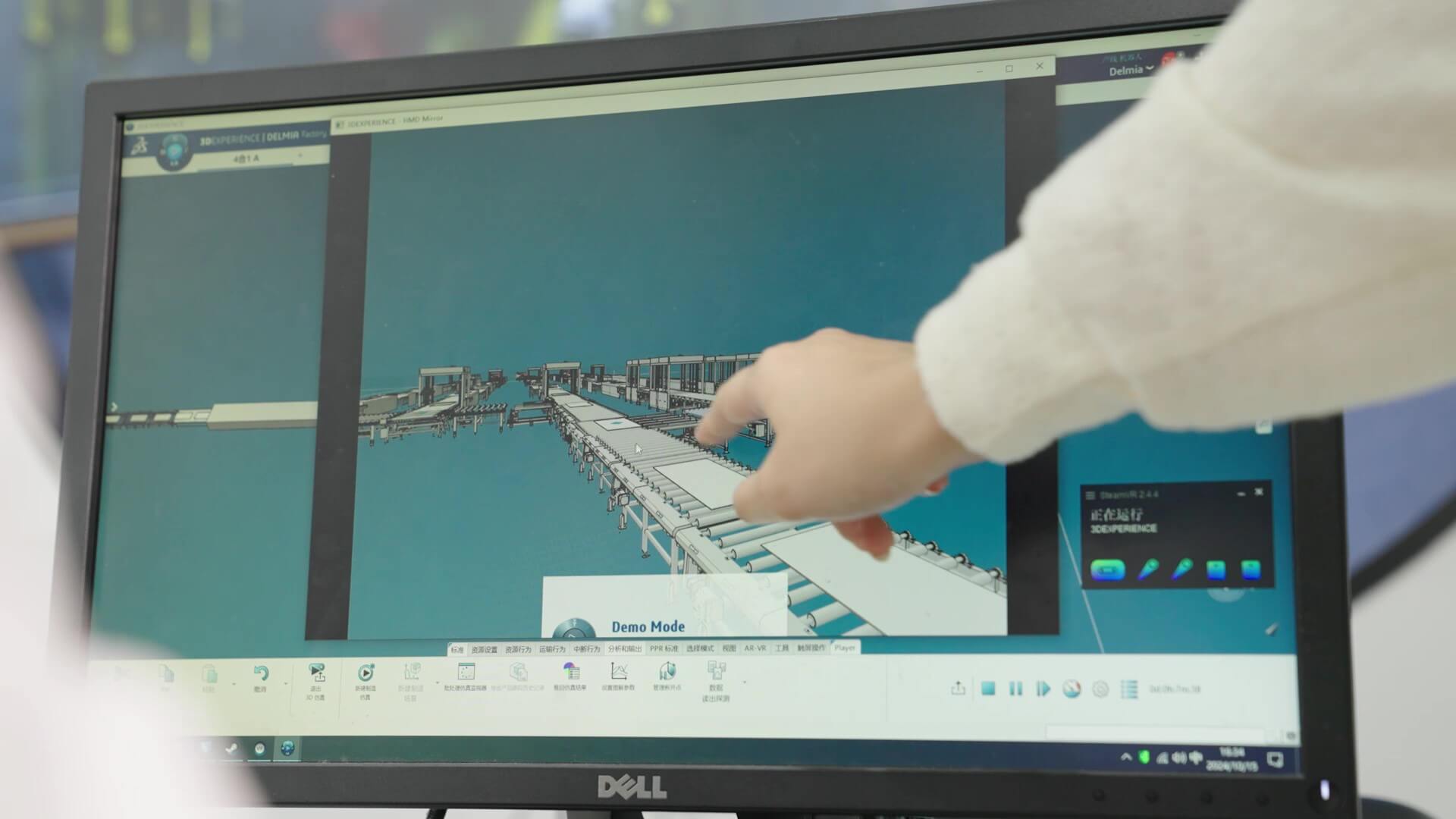

Now that its team members have access to the platform, they can use ENOVIA’s PLM module to quickly create a solution specification and layout diagram upon receiving a customer request. If the customer shows interest, the next step is to create a business model of the production line or workstation in DELMIA, using simulations that help the customer to visualize.

Once the order is placed, designers then engineer the structural design of the production line or workstation – the data from which automatically updates the engineering bill of materials (EBOM). This then informs procurement.

“Everything we do is now based on the PLM’s unified database, without causing duplicate designs or incorrect references,” said Wang. “The process of EBOM generation from the design model is straightforward. Before we started using ENOVIA, converting the design model to EBOM was quite cumbersome due to the integrity of the export format. Now that we have integrated the PLM with ENOVIA, we can push the entire BOM to the procurement application module. Since everyone shares the same EBOM, procurement personnel know the entire scope and structure of supplies and the procurement plan is both accurate and easy to formulate.”

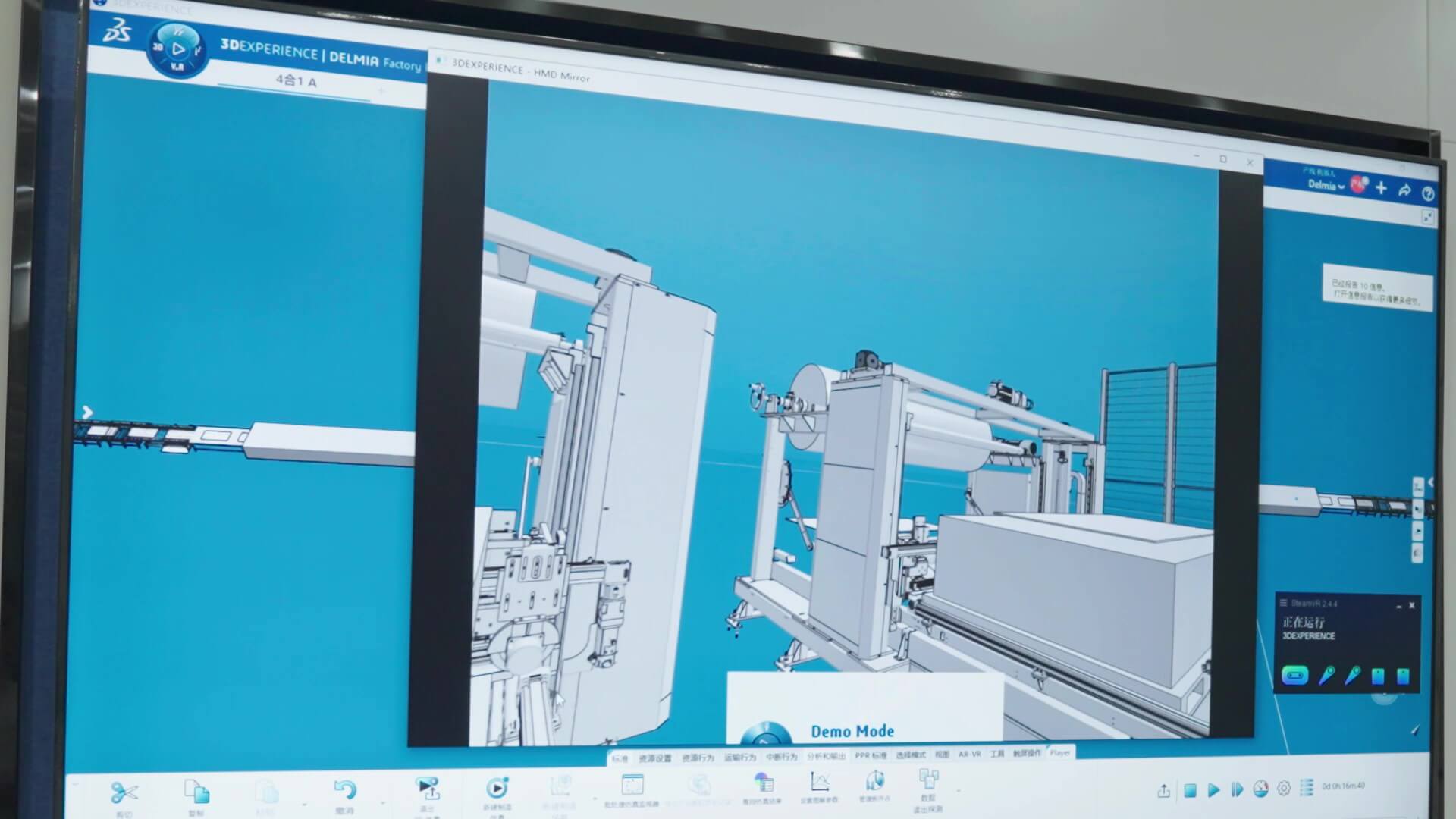

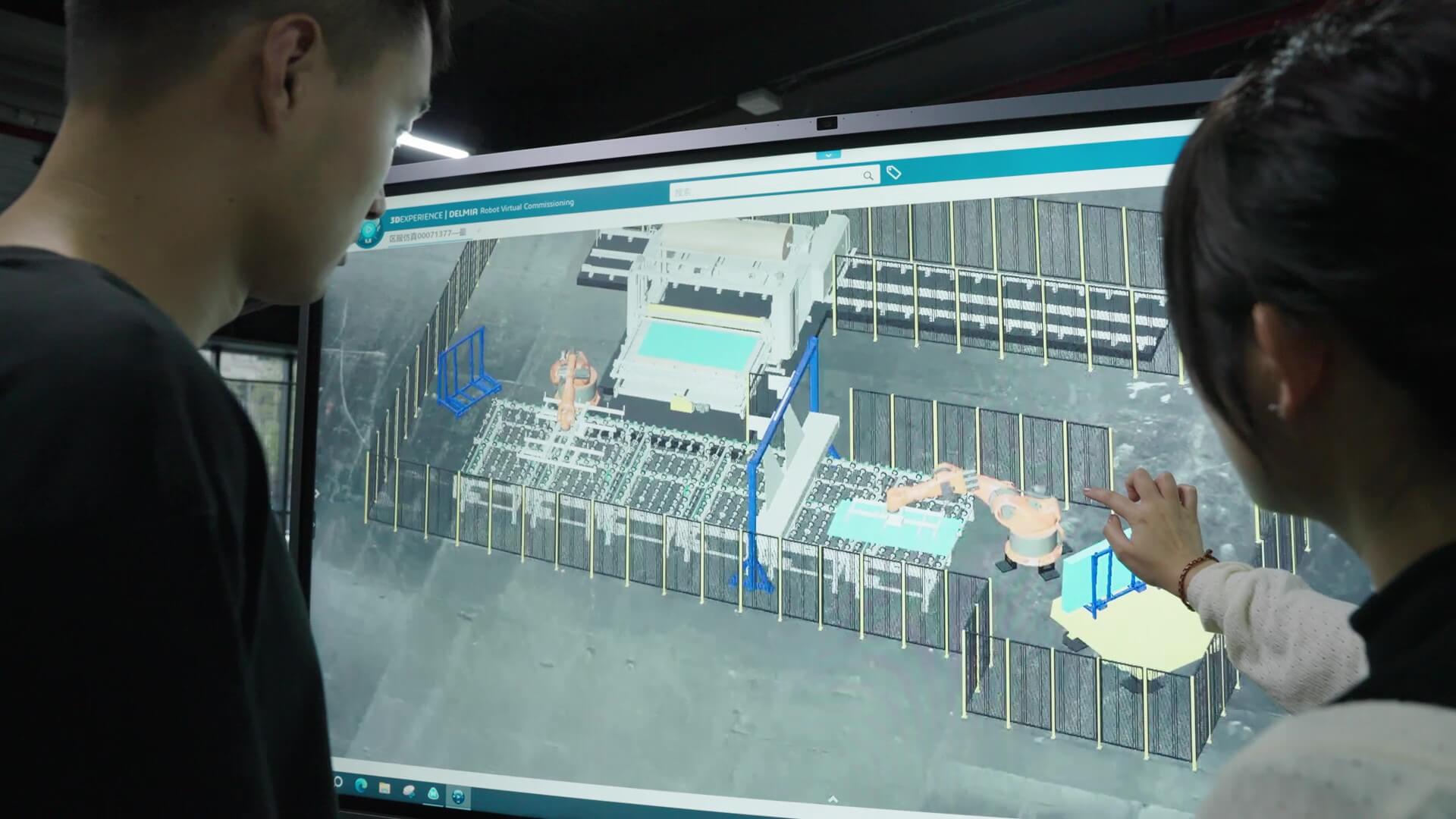

Once the structural design of a new product is finalized, the company can virtually simulate it using DELMIA. “This allows us to visualize each step of the equipment’s process, identify key areas that need improving, and make necessary design adjustments,” said Zhao Man, CNBM Triumph Robotics’ proposal engineer from the robotics engineering business unit. “This marks the post-structural design phase. As we progress and complete the entire equipment design, we conduct detailed simulations to assess the equipment’s operation, check for any process interference, and validate these aspects. Following this is the virtual commissioning stage, where electrical engineers verify the accuracy of the robotic automation technology through simulation models.”

Previously, engineers had to go on-site for verification. Now, with DELMIA, this can be done in the office, before any equipment is ordered or manufactured.

Virtual validation

The 3DEXPERIENCE platform’s virtual commissioning capabilities are a game-changer for CNBM Triumph Robotics. In the past, before a new robotic line was physically implemented, it wasn’t easy to verify its effectiveness.

“Previously, engineers had to go on-site for verification. Now, with DELMIA, this can be done in the office, before any equipment is ordered or manufactured,” Zhao said. “Virtual commissioning also compresses on-site verification time into the equipment production process, running parallelly, which reduces overall project time.”

The company also leverages DELMIA’s simulation capabilities to validate factory logistics, including automated guided vehicle (AGV) routes. For example, a factory might insert additional orders into normal workflows, impacting AGV operations. In this scenario, CNBM Triumph Robotics can use virtual simulation to ensure the continuous operation of a production line, even with these orders.

“Logistics systems require appropriate buffer volumes and AGV scheduling. Traditional companies often make conservative AGV allocations, which isn’t cost-effective,” Zhao said. “We use simulations to design logistics routes, determine the number of AGVs needed and verify AGV work modes so that our operations are smooth even when we have increased production. This helps us maximize production volume.”

Far-reaching benefits

Since implementing the 3DEXPERIENCE platform, CNBM Triumph Robotics has not only streamlined and standardized its way of working, but improved project management and quality. “We have reduced time to delivery by 30% and reduced costs, both from labor and from correcting quality issues,” Wang said.

Moreover, the platform has helped the company to improve the employee experience, efficiency, and, as a result, retain valuable talent. “In the past, issues like market demand changes and management problems from company expansion led to high workloads, increased pressure, and extended business travel cycles,” Gao said. “Now that there are fewer design quality issues and troubleshooting is far more precise, issues can be solved quickly and there’s less need for travel. This means less pressure on our employees and increased customer satisfaction.”

Scaling for the future

CNBM Triumph Robotics’ commitment to improving its operations won’t stop here. By collaborating with Dassault Systèmes to visualize the distribution and flow of dust during cement loading and unloading through simulation, the company plans to improve worker safety by reducing dust inhalation.

It is also exploring how the 3DEXPERIENCE platform can transform the final stage of its process – service delivery. “We employ virtual twin and real on-the-loop technology to connect the 3D model with robotic systems and production line equipment via the internet of things,” Gao said. “This assists customers with diagnostics, equipment upgrades, and training. Though still under development, this function of the platform shows promising potential.”

This isn’t all. CNBM Triumph Robotics is looking to invest in more innovative solutions for its customers such as composite robots and vision technologies – all while broadening its present focus on architectural, photovoltaic, automotive and electronic glass to new innovative glass materials and the wider agriculture sector. The platform will play a crucial role in the company’s ability to succeed in these markets.

“The 3DEXPERIENCE platform will help us with the collaborative design, planning and advanced simulation of new solutions in new sectors,” Gao said. “We have also been exploring further simulation capability from DELMIA, which can help visualize the integration of process, mechanical, and electrical disciplines that are required for us to leverage our new composite robots and agricultural solutions.”

The company is excited by how it can continue to scale and grow in the months ahead. “With Dassault Systèmes on our side, we believe we can transform into a RMB1 billion (€128 million) company in the not-too-distant future,” Gao said.

FAQs

Robotic automation provides higher levels of efficiency and productivity compared to manual processes.

Industrial robots can manage a variety of different parts and material handling processes including painting, welding, assembly and disassembly, packaging and labelling, palletizing, picking and placing, inspection and testing.

Discover more about the Digital Equipment Continuity industry solution experience.

00:00 – 00:25

Gao Changqi, CEO, CNBM Triumph Robotics:

Our R&D building is the first in Shanghai to use integrated photovoltaics – or BIPV.

It’s partially powered by its glass façade, which generated over 200,000kWh of electricity last year.

These photovoltaic glass panels are manufactured with the robotic assembly lines we designed on Dassault Systemes’ 3DEXPERIENCE platform.

00:29 – 01:05

Gao Changqi, CEO, CNBM Triumph Robotics:

When we started serving glass factories, production volume was quite low and the scale of operation was small.

As the industry developed, our company also grew in size and business volume.

Our business expanded from single workstations and small-scale integration to entire production lines and conveyor systems.

We realized we needed standardized processes to avoid making mistakes and duplicating our work.

Now that we’ve implemented the 3DEXPERIENCE platform, our solution team can quickly create a solution specification book and layout diagram that meets our customers’ individual needs when we receive the project brief from a customer.

01:06 – 01:19

Zhao Man, Proposal Engineer, CNBM Triumph Robotics:

DELMIA's virtual validation is very important for us.

Customers love this feature because they can visualize whether the production line’s design meets their specific requirements and needs before production.

01:20 – 01:38

Wang Mengran, Product Manager, CNBM Triumph Robotics:

Project managers can log in to ENOVIA's Project Management section to review the cost and risk of the entire project at the planning level.

All our team members can see their daily tasks at a glance and collaborate on design, thus improving our overall design efficiency.

01:39 – 02:05

Zhao Man, Proposal Engineer, CNBM Triumph Robotics:

Now our engineers can simply log in to the 3DEXPERIENCE platform and confirm the production program before the actual production.

Previously, our engineers had to be on-site to verify the program.

Now, with the 3DEXPERIENCE platform, we are able to do this quickly and easily without having to leave the office, which significantly reduces the overall project cycle time.

02:06 – 02:30

Gao Changqi, CEO, CNBM Triumph Robotics:

Our next goal is to realize innovative breakthroughs, such as focusing on applications in composite robotics.

At the same time, we will concentrate our efforts in two major fields: new glass materials and facility agriculture.

We will continue to rely on the 3DEXPERIENCE platform to scale up and expand.

Focus on CNBM Triumph Robotics

CNBM Triumph Robotics started out in 2003 as Shanghai Eminent Automation Systems. In 2011, CNBM Group Co acquired 70% of the company, making it a state-owned enterprise. Since then, the company has opened its R&D center in Songjiang and earned national awards for its innovative and intellectual property achievements. The company is focused on shaping new developments in industrial automation and robotics through innovative scientific and technological research. It provides robotic automation services and solutions for glass manufacturers, agriculture system solutions, intelligent solutions for information display systems, intelligent logistics, new energy solutions and new material intelligent solutions.

For more information: http://www.shemt.com/

Focus on DAS Tech

As one of the business partners of Dassault Systèmes in Greater China, DAS Tech provides mature product-specific software to various users such as manufacturing enterprises, technology companies, research institutions and universities. It uses advanced CAD/CAE/CAM/PDM/PLM solutions for design, simulation, and manufacturing processes. This significantly improves product invention, design, testing, manufacturing, service and management, helping customers accelerate innovation, improve quality, shorten cycles and save costs.

For more information: http://www.dastc.com/