Bilfit AG

Bilfit chose Dassault Systèmes’ 3DEXPERIENCE platform including the Single Source for Speed industry solution experience to rapidly program and simulate the machining of complex parts.

From sanitary equipment to complex parts manufacturer

When Mr. Othmar Bilgeri and Mr. Georg Fitz created Bilfit in 1983, they never imagined the direction the company would take a few years later. Initially dedicated to installing sanitary equipment in the home, the owners realized that instead of relying on others to machine the parts they needed, they could be more efficient if they machined them themselves. So they invested in a CNC milling machine. “They then realized that to amortize their investment quickly, they could machine parts for other companies,” Marco Rohner, head of manufacturing at Bilfit, said. “As a result, they gained considerable expertise machining parts for various industries.”

“The company ultimately split into two entities. One dedicated to preventing and resolving problems that arise from water damage, mold and moisture and the other company dedicated to machining parts for multiple industries. In the machining company, our park of machines grew to 35, which enables us to be very flexible and to juggle projects from many industries. Our 5-axis machines can produce up to 30 different parts simultaneously. This differentiates us from our competitors, many of whom are unable to take on ambitious or complex projects. We, on the other hand, can machine just about any part at a reasonable price.”

“Our customers include small businesses as well as industry giants such as Swiss manufacturer of railway rolling stock Stadler Rail, Oertli medical equipment manufacturer, aeronautics supplier, Formula 1 Motorsport racing team and automotive supplier SFS Intec,” Rohner said. “While there are other manufacturers on the market, many of our customers prefer working with a company known for its quality and fast turnaround times, and which is also nearby. Bilfit fits all these requirements,” he said.

Since some of their parts are complex to program, Bilfit needed to improve its efficiency to remain competitive. “We were losing a lot of time programming our CNC machines with our old system,” said Rohner. “It was file-based and error-prone because files were sometimes lost or accidently deleted, which caused problems. So we decided to look for a better solution and chose Dassault Systèmes’ 3DEXPERIENCE® platform and the Single Source for Speed industry solution experience to optimize our production processes.” CENIT, a Dassault Systèmes business partner installed the platform at Bilfit and was responsible for employee training. “After a short introduction to the new system, the users felt comfortable with it,” Rohner said. “Their approach delivered the right solution to our business needs along with a rapid ROI. We have a very good relationship with CENIT.”

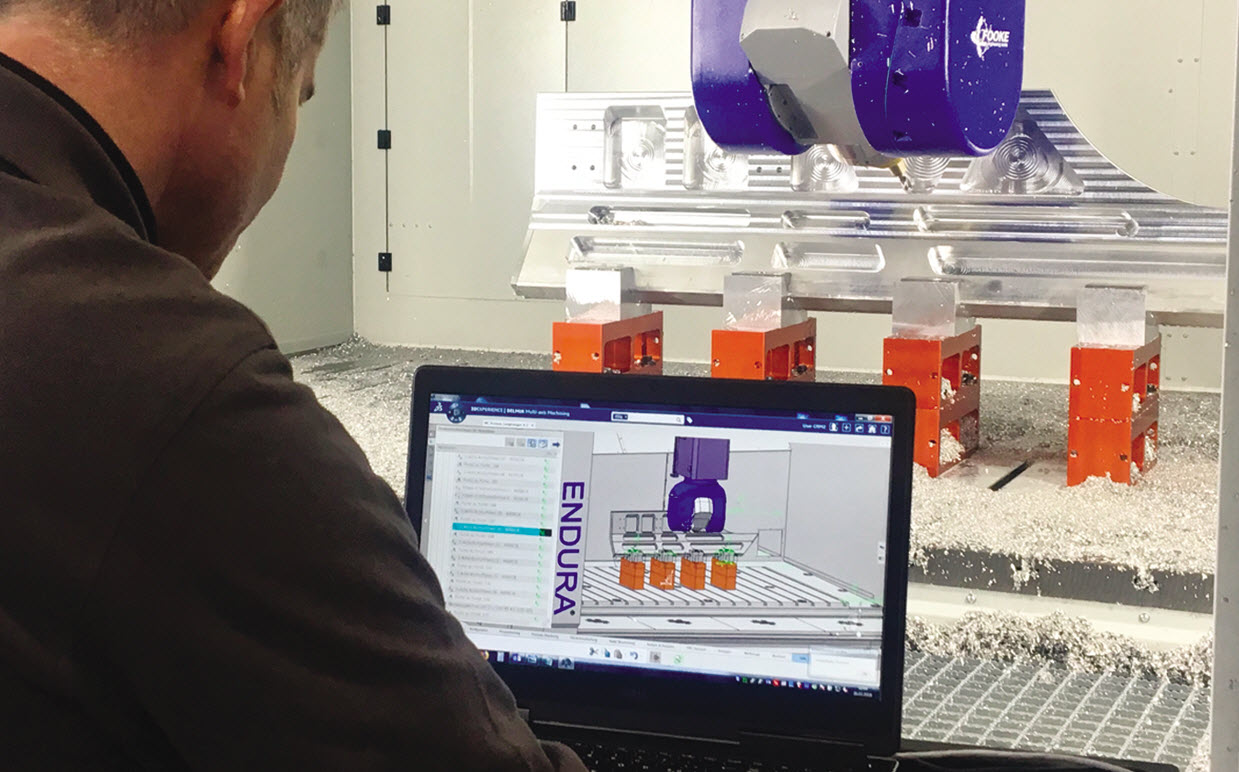

“With Single Source for Speed , we can rapidly program complex parts and store all our information, from the designed part to the manufactured end-product, all in one integrated platform,” Rohner said. “Our intellectual property is safe and can be reused years from now on new projects. For example, when we receive a new design we map it against an existing one to try and reuse already-developed NC programs as much as possible to increase our productivity and deliver parts faster to our customers. Another advantage is that many of our customers also use the 3DEXPERIENCE applications, so exchanging information with them is fast and easy.”

Expanding its business

To attenuate the effects of economic downswings, Bilfit has expanded its business to become a full solution provider for its customers, also assisting them with their engineering needs. “Our core business is manufacturing a part entirely designed by our customer. However, we understand that to continue to play an important role in this market, we need to evolve our business,” Rohner said. “We can also design the part for them using the 3DEXPERIENCE platform’s design application CATIA,” Rohner said. “Thanks to our extensive machining experience, we can design for manufacturing, in other words, incorporate manufacturing constraints in the design. In this way, we save time and money during actual production. This is made possible thanks to the fact that design and manufacturing information is integrated in the 3DEXPERIENCE platform.”

To ensure toolpaths are optimum and scrap is kept to a minimum, Bilfit relies on digital simulation to verify machining programs before actual production. “Simulation enables us to avoid tool crashes that can damage machines and parts alike,” Rohner said. “Simulation also saves us time because we can detect errors or interferences along the toolpath before it’s too late and correct them prior to machining the part. There’s less back and forth because we have a machine program that works right the first time. It’s easier for programmers to simulate a five-axis machine in 3D rather than in 2D because they can visualize what they’re doing. They can also verify from the beginning that a part isn’t too big for the machine. Finally, if the customer makes a design change, we can import it in CATIA and the system automatically updates the NC program. This, too, is an advantage of an integrated solution,” he said.

Bilfit has three different production sites and before transferring its machines from one building to another, previsualizes their installation in a digital environment. “We lay out the shop floor and equipment digitally and simulate the trajectories of the machines when installing and moving them around to make sure they fit,” Rohner said.

We’re well prepared for our future challenges thanks to the 3DEXPERIENCE platform.

Embracing the 4th industrial revolution

The advice Rohner has for small or medium-size companies considering a transition to an integrated platform with 3D design and simulation tools is to look at the big picture and not be afraid of big systems. “Industry 4.0 (or the 4th Industrial Revolution) is upon us and an integrated digital platform will enable companies to negotiate their digital transformation. The benefits far outweigh the risks such a transition can engender. We must transform our way of working if we want to be part of this new digital community and capture new business opportunities.”

For Bilfit, the 3DEXPERIENCE platform helps the company modernize its approach to manufacturing in line with the market’s expectations, says Rohner. “Parts are more complex than before. Take the rail or car industries, for example. In the past, wagon or automotive parts were very easy to manufacture. They were a series of basic, straight-edged shapes. Today, expectations are different. Companies want lighter more stylish wagons or cars to seduce their customers, which means designing parts with less material and more sophisticated shapes. Machining such shapes is complicated and can only be efficiently and cost-effectively done with a high-performance 3D system.”

In the future, Bilfit will extend the use of the 3DEXPERIENCE platform to generate manufacturing bill of materials (MBOM) and to implement role-based management of their workflows. The company also wants to reinforce collaboration between its three production sites using the platform as their unique access point. “These are all part of our Industry 4.0 strategy,” Rohner concluded.

Focus on Bilfit AG

Bilfit AG is specialized in machining, CNC turning, CNC milling and engineering services.

Employees: 40

Revenue: 15 Mio CHF

Headquarters: Diepoldsau, Switzerland

For more information www.bilfit.ch

Focus on CENIT

CENIT empowers sustainable digitalization. Our solutions are based on innovative technologies in product lifecycle management, the digital factory and enterprise information management. CENIT consultants provide customers with end-to-end advice to ensure that solutions are implemented with an understanding of the entire value chain. With a holistic approach and based on trusted partnerships, CENIT takes responsibility for solutions on behalf of our clients. CENIT has been helping prestigious customers in key industries to gain competitive advantages for over 30 years.

For more Information: http://www.cenit.com/