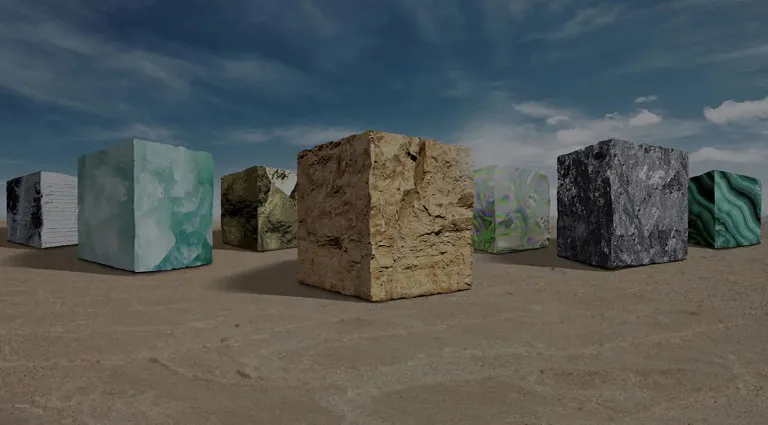

Metals & Minerals

Optimize Production and Productivity. In addition to supporting actors in both the Mining and Metals and Minerals industry segments, Dassault Systèmes solutions link both together to encompass the full value stream - from extraction to final product and delivery.

Challenges faced by the Metals & Minerals Industry

Discover how you can master them

- Maintaining Profits

- Energy Costs

- Sustaining Productivity

- Customer Satisfaction

- Environmental Impact

Maintaining Profits

Volatile market prices and fluctuating demand are outside the control of metals and minerals producers. It therefore becomes mandatory to avoid common obstacles to profitability such as high inventory levels, poor delivery performance, low yield, and excessive waste. The ability to optimize and re-optimize processes and operations to meet demand achieves this by balancing production and enabling more nimbleness in the allocation of inputs and assets.

Energy Costs

One of the greatest expenses and impacts on profits metals and minerals producers face is energy costs. By understanding holistically how processes work together across production and supply chains, schedules and routings can be optimized and made more efficient. This minimizes the steps involved and along with it associated energy consumption while still yielding the highest throughput levels.

Sustaining Productivity

From refining to smelting, and on to customer delivery, there are many resource and labor inputs feeding plants and logistical processes that impact productivity. By enabling collaboration and greater visibility across all planning time horizons, planning processes become integrated, allowing for better insight into production constraints and anticipation of bottlenecks. The resulting master production schedule and process optimization, including what needs to happen now, reduces lead times and enables more effective execution.

Customer Satisfaction

Maintaining customer satisfaction is more imperative as competition increases. Greater visibility into the state of their operations in real time allows metals and minerals companies sales teams to be confident that they are making accurate delivery promises to their customers. Management of customer orders through to fulfilment ensures that supply is available and delivered to quality specifications and on time.

Environmental Impact

At a time of increasing environmental regulations, society’s move to use more recycled and lower environmental footprint materials is putting more pressure on metals and minerals producers to adapt to new business realities. By following strategies that optimize the use of production outputs and plant utilization, scrap can be minimized and re-incorporated into production more efficiently. With a more collaborative and comprehensive planning view of its ecosystem, in eco-industrial parks for example, producers can also divert more energy or materials from ending up as waste.

Decarbonizing our world's building blocks

Process industries make up the modern world, but they are also responsible for around a fifth of global CO2 emissions. Digitalization can create a clear pathway to decarbonization.

Discover our Customer Stories

Explore our Industry Solution Experience

Learn more about how our industry solutions can help you achieve your professional ambition and business objectives.