AURORA

A new dawn for sustainable innovation... by design.

An installation by architect Arthur Mamou-Mani & Dassault Systèmes Design Studio.

Design in the Age of Experience: unveiling the AURORA installation

To coincide with the UN Climate Change Conference (COP26), the Design Museum will host an exhibition entitled “Waste Age: What can design do?” showing what design can do to tackle the critical problem of waste and its environmental consequences across the globe.

Dassault Systèmes is proud to be unveiling the AURORA installation for the opening of the exhibition in London. AURORA was born out of a collaboration between Dassault Systèmes Design Studio & Arthur Mamou-Mani, a formidable architect who is passionate about parametric design, experimentation, digital fabrication and sustainable architecture. The perfect mix for our Design for Life program.

Welcome to our 3rd installment of Dassault Systèmes’ Design in the Age of Experience initiative, exposing visitors to design’s transformative power in action. In the past years, we addressed air pollution with Kengo Kuma’s magnificent “Breath/ng” installation, and data-driven design with Morphosis’ “Interfaces,” both revealed at Milan’s Design Week.

AURORA manifests the convergence of art, science and industry, united and empowered by technology, inspiring a new aesthetic for a renewable world. Find out more.

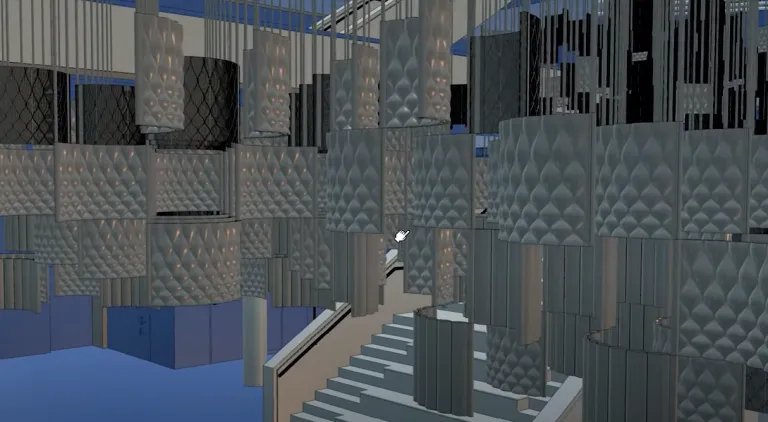

VirtualAURORA Installation

Push the button to launch the experience and discover it as if you were in the museum!

Sustainable design in practice

Discover how our collaboration unfolded… get inspiration for your own transformation for more sustainable innovation processes.

- #MaterialForLIfe

- #DesignForLife

- #FabricationForLife

Switching to Sustainability

Material Sourcing

Our quest for alternatives to fossil-based plastics led us to PLA, a mechanically strong, non-toxic & 100% recyclable thermoplastic derived from renewable and traced resources (potato, wheat & corn starch).

Sustainability intelligence

We took advantage of Life Cycle Assessment tools to evaluate the sustainability impacts of every choice made throughout the design & development process.

3D-Print Testing

PLA is an ideal material for circular experimentation, as it can be crushed and 3D printed repeatedly. From the start, we embraced the inevitable printing irregularities, celebrating their unique aesthetics.

Molecular Analysis

We compared PLA to regular ABS, the most ubiquitous of fossil-based plastics. PLA demonstrates similar mechanical strength and plasticity but requires less energy to produce, thanks to a lower melting temperature.

Material Rendering

We could refine lighting & textures early in the design process. Live Rendering capabilities allowed us to deep dive into a photo-realistic look & feel of our material in context.

New Patterns for assembly & modularity

Upstream Thinking

Identifying disruptive creative propositions that have positive impacts cannot happen in a vacuum. We reached out to our online collaborative communities of innovators to build a comprehensive body of inspirational architectural concepts on shared dashboards.

Generative Design

For us, design is a digital craft. After crafting the modules in 3D, we went on to design the larger architectural system. Our xGenerative Design solution allowed the team to formalise architectural concepts, with a creative focus on assembly, disassembly & modularity.

3DEXPERIENCE Twin

The modules were assembled in a virtual 3D model of the Design Museum, creating a virtual twin experience of AURORA. With the 3DEXPERIENCE® platform, we could run precise scientific simulation and Life Cycle Assessment on our artwork-in-progress.

Light Design & Light Simulation

Live Rendering & Ambiance tools made it possible to develop high-end, photo-realistic visuals at any stage of the process, enabling us to make fully informed decisions on colour and material in context.

Airflow & Physical Simulation

Aesthetics and functionality work hand in hand. With PowerFLOW, we simulated the airflow around the structure to ensure a safe and enjoyable experience for visitors.

Regeneration, not pollution

3DS Marketplace

AURORA is made in London, courtesy of Mamou-Mani’s fabrication hub FabPub – a member of our 3DEXPERIENCE Marketplace. The marketplace, which operates on the 3DEXPERIENCE® platform, connects designers, engineers and production planners with 3D-print and manufacturing service providers.

Reuse and Repurpose

Re-use of a system saves energy and resources, so it is far more efficient than recycling. Our community of makers and designers is working on ways to repurpose modules and allow them to continue delivering value.

Crush & Reprint

Remarkably, PLA can be 3D printed, crushed and printed again… Follow our designers-in-residence, Kate Reed and Jason Pohl, as they use principles of biomimicry to create new forms – in full circular mode.

Compost - A new dawn

PLA is a natural material that also is industrially biodegradable, thanks to a clean-compost process. Modules that cannot be re-used, repurposed or recycled will be turned into biomass — an optimized end of life to our architectural artwork.

Discover more

Dassault Systèmes & the 3DEXPERIENCE platform

Dassault Systèmes’ 3DEXPERIENCE® platform is the catalyst for uniting artists, scientists and makers in a dynamic process of renewable innovation. By collecting and displaying knowledge from dozens of disciplines via virtual twin experiences – scientifically accurate simulations of objects and the world in which they will exist – the platform provides a space for collaboration. For the first time, virtual twin experiences enable us to conceptualise and fully understand our creations’ renewal potential.