PLM: Drive Innovation with Product Lifecycle Management

Streamline product development from design to end-of-life.

What Is PLM Software?

Product Lifecycle Management (PLM) software systems have long been a standard for how businesses optimize the development, quality and profitability of manufactured goods. PLM provides a comprehensive approach to managing information across a product's entire journey, from initial concept to final retirement.

A PLM solution encompasses all aspects of a product's life, including design, development, manufacturing, marketing, support and recycling. PLM software is essential for businesses because it standardizes processes and connects stakeholders around a shared product definition.

The History of Dassault Systèmes in PLM

- Origin and evolution

- Dassault Systèmes' role

- PLM vs PDM software

- PLM on the 3DEXPERIENCE platform

Origin and evolution

The concept of PLM originated in the 1980s within the aerospace and automotive industries. As products became increasingly complex, these industries required sophisticated systems to effectively manage the vast amounts of data generated throughout the product lifecycle.

The initial phase of PLM was marked by the development of Computer-Aided Design (CAD) tools and Product Data Management (PDM) systems. These tools enabled engineers to create detailed digital models and manage product-related information systematically.

Dassault Systèmes' role

The ENOVIA brand of Dassault Systèmes was founded in 1998 to develop the first 3D PLM system as a way to transform product innovation across the value network and through all stages of the product lifecycle.

With the launch of the 3DEXPERIENCE platform in 2012, Dassault Systèmes expanded the PLM offering to go beyond products and include the experiences they provide.

PLM vs PDM software

PDM and PLM are both software systems used in product development, but they serve different purposes:

- PDM: Focuses on managing product data (CAD) through the design and engineering phases of development.

- PLM: Expands on PDM functionality by governing all product information across all stages of the lifecycle from conception to disposal, including data, processes and collaboration.

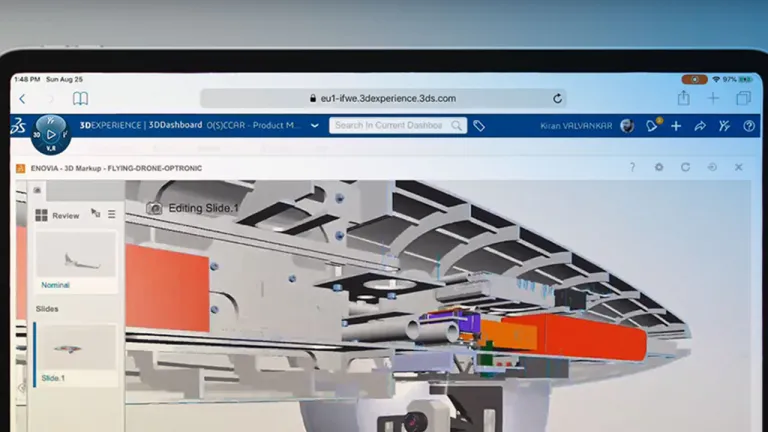

PLM on the 3DEXPERIENCE platform

The 3DEXPERIENCE platform, goes beyond traditional PLM by integrating design, engineering, simulation and manufacturing data. Connecting people, ideas and data into a unified environment, enhances collaboration across the value network and transforms traditional processes.

With the model at the core of all business processes, the platform enables efficient model-based systems engineering (MBSE) across the enterprise. As a result, the platform drives significant improvements in time-to-market, quality and operational agility.

Key Benefits of Product Lifecycle Management Software

Product Lifecycle Management and Sustainability

Enabling a generative economy and sustainable innovation through PLM.

Driving eco-friendly innovation

PLM is pivotal in driving sustainable practices and eco-friendly innovation across industries. By integrating sustainability considerations into every stage of the product lifecycle, PLM enables companies to reduce their environmental impact while improving efficiency.

Life Cycle Assessment (LCA) tools within PLM systems allow businesses to evaluate and optimize the environmental footprint of their products from cradle to grave.

This holistic approach helps identify opportunities for reducing resource consumption, minimizing waste and improving energy efficiency.

It will be possible to generate multiple lives of things — waste is becoming a resource for new products.

It’s the PLM of the 21st century: Dassault Systèmes invented Product Lifecycle Management in the 1990s and now we virtualize the multiple cycles of lives of things.

Product Lifecycle Management Across Industries

Discover how Product Lifecycle Management is applied in various industries and how our PLM solutions stand above the rest.

Driving Innovation with Dassault Systèmes’ PLM Solutions

Empowering innovation and efficiency, ENOVIA transforms business with the 3DEXPERIENCE platform’s scalable, cloud-based PLM solutions. This connected approach enhances collaboration, streamlines workflows and drives data-driven decisions to optimize operations and maintain a competitive edge.

Next-Gen PLM on ENOVIA

Innovation is essential, but balancing efficiency with rapid breakthroughs is challenging. ENOVIA PLM solutions transform operations, enabling scalability and accelerated innovation. Lead your industry's future with ENOVIA.

Cloud-Based PLM solutions

The 3DEXPERIENCE platform on the cloud offers scalable, flexible solutions accessible from anywhere. It enhances global collaboration, reduces IT costs and helps businesses quickly adapt to market changes.

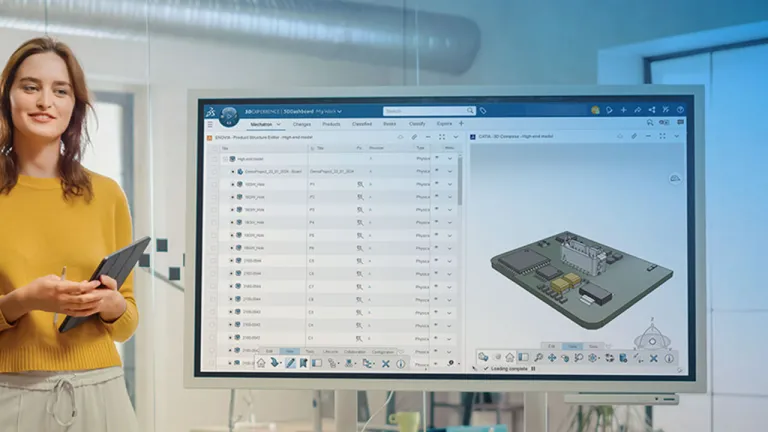

One Platform, Endless Possibilities

The 3DEXPERIENCE platform unifies product lifecycle management, enabling real-time collaboration across teams. By breaking silos, it fosters efficiency, innovation and a single source of truth for all product data.

Experience the Real-World Value of PLM Solutions

Explore how companies of various sizes have benefited from implementing Product Lifecycle Management solutions.

Use Cases: Key Business Functions of PLM Software

Discover how PLM enhances key business functions — from quality assurance to cost management — by streamlining processes, improving collaboration and ensuring compliance across the product lifecycle.

BOM: bill of materials management

BOMs specify the components incorporated into a product. Effective BOM management serves as the cornerstone for evaluating and implementing changes within the product structure, thereby ensuring consistency, quality and regulatory compliance throughout its lifecycle.

Quality assurance & compliance

Successful product innovation requires strategic portfolio management. PLM allows companies to define, track and align product roadmaps with business goals. Dassault Systèmes’ solutions connect portfolio management with product development, ensuring projects stay on schedule and aligned with market needs.

Supply chain optimization

A complex global supply chain requires visibility and agility. PLM enables real-time supplier collaboration, allowing businesses to model sourcing scenarios, anticipate risks and align decisions with cost and sustainability goals. Dassault Systèmes’ solutions help optimize supply chain flows, reduce lead times and improve resilience.

Cost management & profitability

Managing costs from design to production is key to profitability. PLM integrates real-time cost tracking, helping teams anticipate financial impacts early. Dassault Systèmes’ solutions provide a unified view of expenses, enabling proactive adjustments and profitability optimization across the product lifecycle.

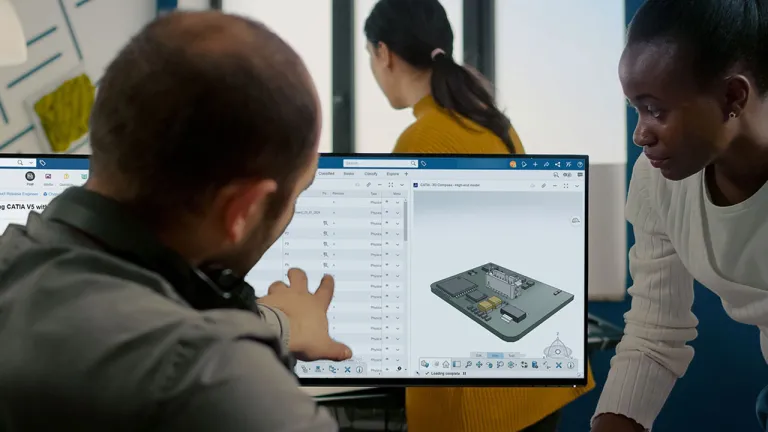

Multi-discipline design collaboration

Modern products require seamless collaboration between mechanical, electrical and software teams. Dassault Systèmes’ PLM solutions break down silos, providing a unified digital environment where engineers can work in parallel, ensuring data consistency and accelerating development cycles.

Product development & portfolio management

Successful product innovation requires strategic portfolio management. PLM allows companies to define, track and align product roadmaps with business goals. Dassault Systèmes’ solutions connect portfolio management with product development, ensuring projects stay on schedule and aligned with market needs.

Engineering data management & security

Managing and securing engineering data is essential for innovation. PLM centralizes design files, simulations and documentation, ensuring controlled access and regulatory compliance. Dassault Systèmes’ solutions offer data encryption, version tracking and collaboration tools, reducing risks and improving efficiency.

Virtual Twins: Expanding PLM Beyond Design and Engineering

A virtual twin represents a product or system as it exists now, but also how it was designed, tested and manufactured in the past and how it could be operated and maintained in the future.

Virtual Twin Experiences

Virtual twins are everywhere, for everything.

They model the full lifecycle, behavior, and evolution of a product, starting with a 3D representation of its shape and properties. They optimize design, materials and processes while ensuring traceability and supporting PLM throughout the lifecycle.

Virtual twins bridge the physical and digital!

In order to generate and protect the most valuable intellectual property, it is of critical importance to create virtual twin experiences of everything for everyone that harmonize product, nature and life.

Dassault Systèmes' Key Values in PLM

Innovation-driven solutions

Dassault Systèmes prioritizes cutting-edge technology to drive product innovation.

Sustainability focus

The 3DEXPERIENCE platform integrates eco-friendly practices throughout the product lifecycle.

Industry-specific expertise

Dassault Systèmes offers tailored PLM solutions for industry-specific needs.

End-to-end integration

The platform provides seamless, real-time connectivity for all stakeholders and across all product lifecycle stages.

Customer-centric approach

Dassault Systèmes focuses on meeting unique client needs and fostering long-term partnerships.

Anytime, anywhere availability

Break free from IT constraints and unify your business with real-time collaboration on a cloud-based platform.

Want to Go Further?

Explore the content below to learn more about Dassault Systèmes and Product Lifecycle Management.

Get in Touch with Our Experts

Fill in the form to have a Dassault Systèmes expert contact you to answer your questions and discuss any of your needs.

Let’s transform your PLM journey together — contact us today!

Product Lifecycle Management FAQs

Yes, small and medium businesses can benefit significantly from PLM. Modern cloud-based PLM solutions offer scalable and cost-effective options that can help businesses of all size improve efficiency, reduce errors and compete more effectively with larger companies.

The main stages in PLM software include concept development, design, manufacturing, distribution and end-of-life management. Each stage involves specific processes and tools to optimize product development, quality and performance throughout its lifecycle.

Here's how a PLM system typically works:

- Centralize product-related data.

- Facilitate collaboration and workflow management.

- Support design and engineering with tools for modeling and simulation.

- Manage change and configuration throughout the lifecycle.

- Enable supplier collaboration and procurement processes.

- Manage quality and compliance.

- Provide traceability and analysis of product information for informed decision-making.

PLM benefits all industries. Historically, it has been adopted in engineering-intensive industries such as aerospace, automotive and industrial equipment. However, modern PLM systems have evolved to support adoption by all industries and organizations of any size.

Key challenges include resistance to change, data migration and integration with existing systems, ensuring user adoption and aligning PLM strategy with business goals. Overcoming these requires strong leadership, comprehensive training and a phased implementation approach.

PLM software contributes to innovation by facilitating collaboration, streamlining processes and providing a centralized platform for idea management. It enables faster prototyping, efficient testing and data-driven decision-making, accelerating the development of innovative products.

Cloud-based PLM offers several advantages over traditional on-premises solutions, including lower upfront costs, scalability, remote accessibility and reduced IT maintenance. Cloud-based PLM allows teams to collaborate in real-time from anywhere, facilitating greater flexibility and responsiveness.

Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP) are both software systems used in businesses, but they serve different functions within an organization:

- PLM (Product Lifecycle Management): Manages product development lifecycle, focusing on design, manufacturing and collaboration.

- ERP (Enterprise Resource Planning): Integrates core business processes like finance, HR and supply chain management across departments.