The intricacies of injection mold design

The majority of modern industrial sectors worldwide now use injection mold design, from the automotive and aerospace industries to consumer goods manufacturers and producers of medical equipment. Virtually every piece of equipment or product we use in our daily life has been produced using injection molding.

What is injection mold design?

Producing intricate components with injection molding is an integral part of the manufacturing process for all kinds of companies. The injection molding process itself involves transferring molten material, such as metal, plastic, or glass, into a fixed mold which then hardens or freezes to create a durable, highly complex object. Injection molding allows for the uniform mass production of parts and components with intricate geometries. Injection molding is fast, accurate, and reliable.

At first glance, many people assume that this remarkable manufacturing technology is a recent invention. Not so! It may surprise you to learn that the concept of injection molding was first actually introduced way back in 1872 by John Wesley Hyatt. Hyatt was an inspired American inventor who developed a specialized machine that used a piston to transfer plastic into a mold. His idea was refined by German chemist Arthur Eichengrün, who created the injection molding press in 1919.

The increased demand for components during the Second World War saw injection molding used on a massive scale. More recent advances in the injection molding process during the 1970s and the 1990s resulted in more efficient injection molding techniques such as screw injection molding, blow molding, compression molding, and vacuum molding.

Injection molding is now the most commonly used manufacturing technology in the world. It has been reported that the global injection molding market is now worth more than a staggering US$261.8 billion and is expected to grow at a tremendous rate with a compounded annual growth rate of 4.8% during the next decade!

Discover our injection molding solutions in the store

Designing customized injection molds requires highly sophisticated computer aided design (CAD) software. Dassault Systèmes is well-known as a global industry leader in developing versatile, innovative, and efficient cloud-based CAD injection mold design software.

Mechanical Designer

Design on your terms with expert applications that cover the end-to-end mechanical design process

Sheet Mechanical Designer

From mechanical design to manufacturing, accelerate your processes at an affordable price.

What are the advantages of injection molding?

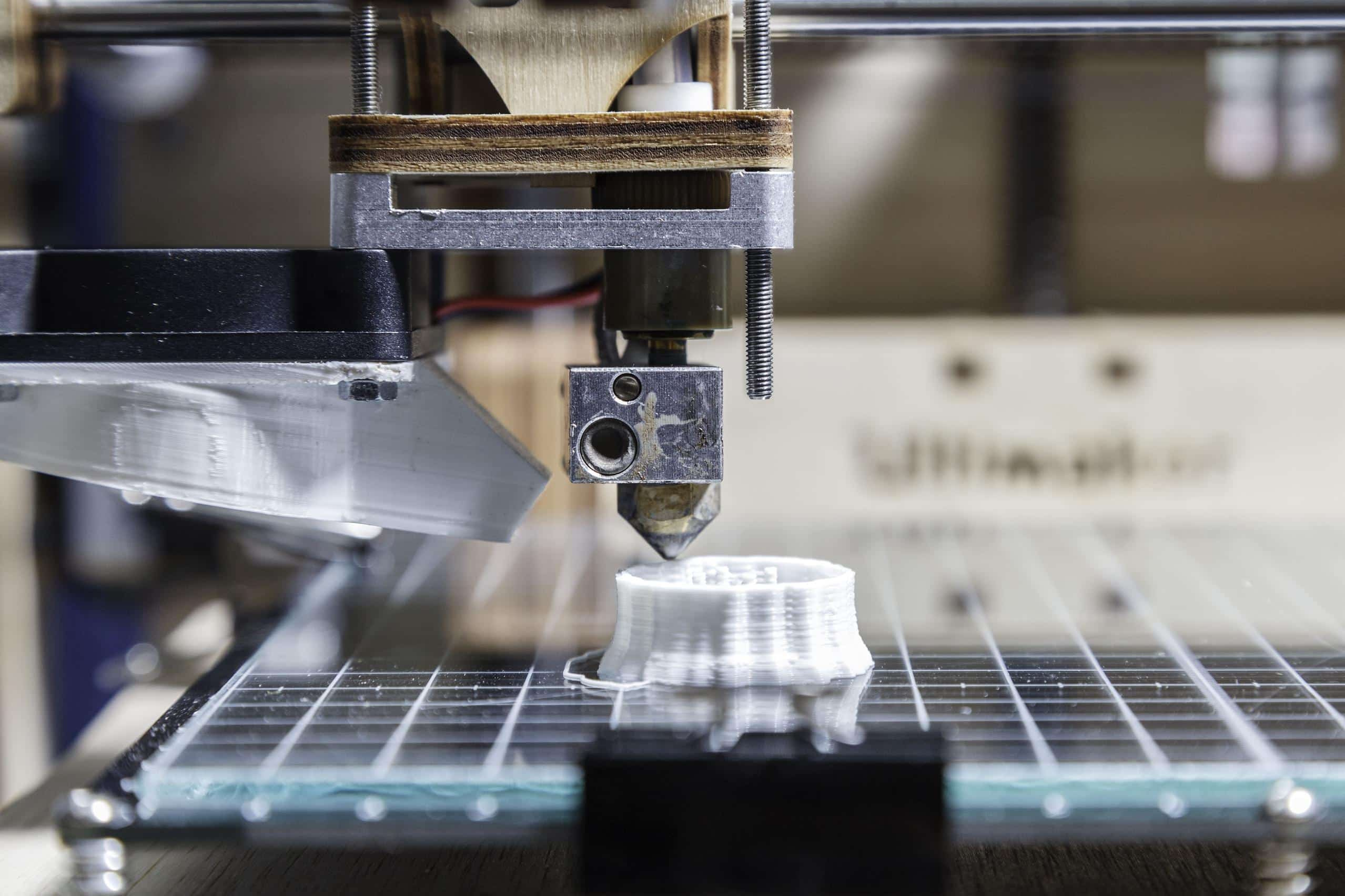

Products can be produced using injection molding techniques in a short space of time for a relatively low cost when compared to other methods, such as 3D printing, for example. The low cost per unit and rapid rate of production that injection molding enables cannot be achieved with any other manufacturing process.

Injection molding enables manufacturers to produce high volumes of products or components that are all uniform in shape. Once a mold has been created, a company can use it repeatedly to manufacture thousands of products without the need for retooling.

Many different materials can be used for injection molding. While plastics are the most common material for injection molding, thermoplastic, glass, metal, or composite materials can also be used. Excess material produced during the process can be collected and fed back into the injection molding machine, further reducing costs and eliminating waste.

The injection molding process

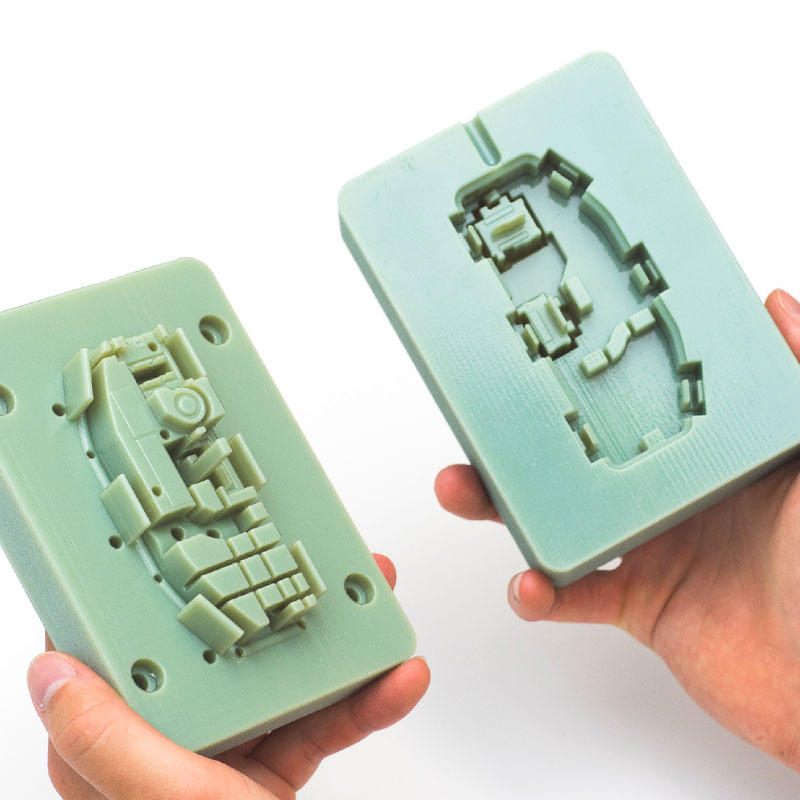

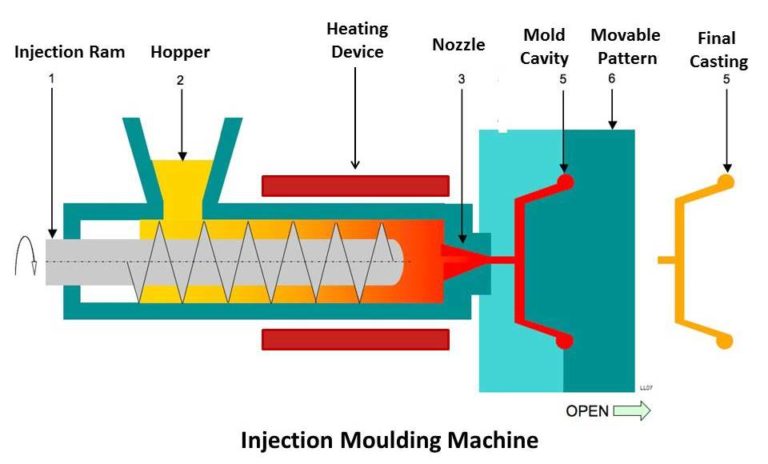

Sometimes referred to as a press, an injection molding machine produces products, tools, or equipment. The majority of these machines are used for plastic injection molding. An injection mold is the tooling machinery used to create components or products. It is part of a custom injection molding machine. It is made of two halves that form a cavity that can be filled with material.

The steps involved in the injection molding process are as follows:

- Step 1: Design the mold

- Step 2: Create the mold

- Step 3: Inject the molten plastic (or other material)

- Step 4: Cool the plastic (or other material)

- Step 5: Remove the part

Filling and stamping

Material such as metal, glass polycarbonate, or polypropylene is fed into the hopper. The material can then be mixed with an additive. It is then fed to the barrel where the heating unit melts the material. Next, the screw or injector ram compresses the material and pushes it through a nozzle into the mold cavity itself.

At this point, a hot stamping process may be used to add colors, logos, or even information to a product. A molding company may choose to forgo the stamping process if, for instance, they are producing a prototype that is not meant for sale.

Another form of making an injection-molded product is overmolding. Often called two-shot molding, this process involves molding multiple components together to produce one final product.

Typically, an injection molding machine is made up of:

- A material hopper

- A barrel

- A screw plunger or injection ram

- A heating unit

- A mold cavity

- A mold core

- A mold base

- A runner system

- A cooling unit

- A gate

- Ejector pins

Browse all the Dassault Systèmes store applications

We feature in our store some of our best software to design, collaborate and innovate throughout the entire product lifecycle.

Content related to injection mold design

The basics of injection mold design

An injection mold can be made using hardened or pre-hardened steel, aluminum, or a beryllium-copper alloy. It takes high levels of skill and experience to design an injection mold that can be used to produce thousands of quality products molded to a uniform size and shape.

Creating reliable, durable, and complex molds requires the use of powerful CAD injection mold design software. Top designers and engineers from across the globe turn to Dassault Systèmes for proven, professional, and precise injection mold design software.

Injection molding, simply revolutionizing manufacturing

There is absolutely no doubt that injection molding has revolutionized the way we produce goods. It is an incredibly effective method of manufacturing even the most complex tools, parts, or products.

Injection molding enables manufacturers to use a variety of materials and guarantees reliability and uniformity. As an added benefit, they can reuse waste materials. Anything from common consumer goods we use every day to automotive parts to specialized medical equipment can be made cheaply and quickly.

Making products that are sustainable and less resource intensive is now a priority for companies and governments across the globe. Advances in CAD design software have expanded the possibilities of injection mold design and enabled the production of more environmentally friendly products. It is clear that industries of all types will continue to rely on injection molding in the years to come.

Explore Dassault Systèmes solutions

Discover the powerful browser-based modeling solutions from Dassault Systèmes. You can design whatever you wish, wherever you are with 3DEXPERIENCE.

Connecting data & people to foster innovation

The 3DEXPERIENCE platform on the cloud gives you access to a various set of applications that allow you to design, simulate, inform and collaborate on a project.

Discover Dassault Systèmes store solutions for injection molding

Designing customized injection molds requires highly sophisticated computer aided design (CAD) software. Dassault Systèmes is well-known as a global industry leader in developing versatile, innovative, and efficient cloud-based CAD injection mold design software.

Dassault Systèmes’ store solutions for injection molding include:

- CATIA Sheet Metal Designer

- CATIA Mechanical Designer

- SOLIDWORKS Cloud Offer

CATIA Sheet Metal Designer

This easy-to-use, entry-level mechanical design program is perfect for solid and surface geometry for mechanical and industrial projects. CATIA Sheet Metal Designer works together with the innovative 3DEXPERIENCE, delivering awesome collaboration capabilities that are simply unmatched by any rival piece of software!

CATIA Mechanical Designer

Used by manufacturing professionals across the planet, CATIA is an incredibly agile and advanced mechanical design program. This astounding CAD software is powerful enough to be suitable for everything from aeronautical to industrial applications. CATIA Mechanical Designer delivers efficient solutions for complex end-to-end mechanical and object design.

SOLIDWORKS Cloud Offer

Dassault Systèmes SOLIDWORKS Cloud Offer combines two of our most powerful software solutions: 3D Creator and 3D Sculptor. These SOLIDWORKS applications are ideal for non-complex mechanical design and are flexible enough so they can be used by students, first-time designers, or experienced engineers!

Why choose Dassault Systèmes for your injection moldeing needs?

The power of the 3DEXPERIENCE

The 3DEXPERIENCE from Dassault Systèmes gives engineers and designers the tools they require to achieve their design goals.

No matter what industry you work in, Dassault Systèmes provides you with next-generation design solutions. The 3DEXPERIENCE store is your gateway to the phenomenal cloud-based 3D CAD design softwares from Dassault Systèmes. You can create complex shapes in 2D or 3D and collaborate with your colleagues securely and safely in real time.

The 3DEXPERIENCE Marketplace

The 3DEXPERIENCE from Dassault Systèmes gives engineers and designers the tools they require to achieve their design goals.

You can also connect with industrial injection molding service providers via the Make marketplace available on the 3DEXPERIENCE platform. Dassault Systèmes incorporates an on-demand manufacturing platform experts can use to develop complicated products and parts for any application. Expert engineering and design professionals use the 3DEXPERIENCE marketplace to create an incredible array of complex components using a variety of materials.