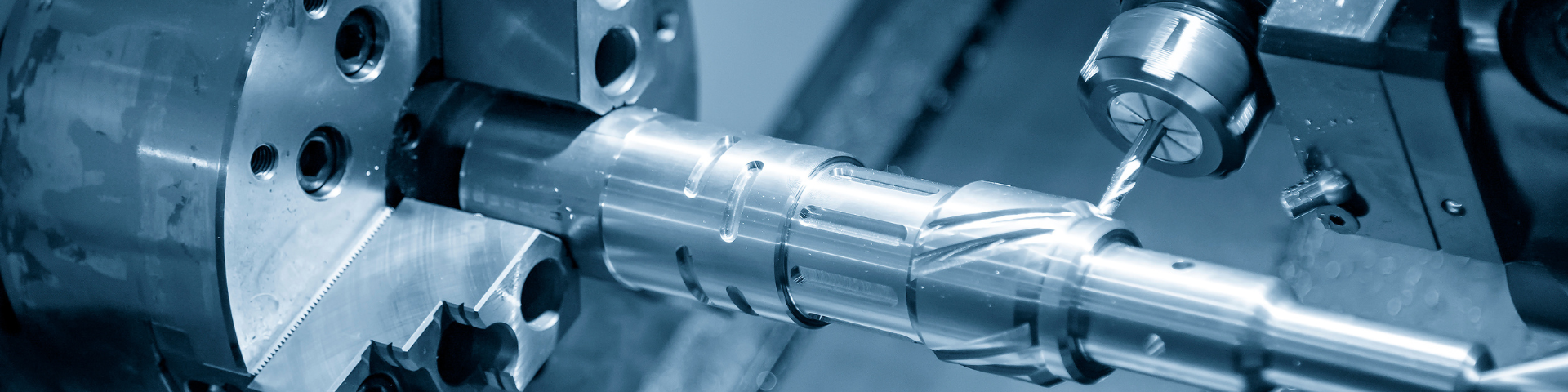

Ep: 34 How to Excel Seamlessly in a Wide Range of Machining Operations

In this episode, Dominique Galmel, DELMIA Fabrication Roles Portfolio Director, discusses the need for DELMIA solutions for machining operations and computer aided manufacturing (CAM) along with insight on industry trends.

Gain shopfloor confidence on a wide range of machining operations

Tune and discover DELMIA Fabrication and how it can help you with a wide range of machining operations. Dominique Galmel explains in detail the workings of DELMIA Fabrication and the machining portfolio. You’ll learn how it is composed of two sections to measure lines of products dealing with the machining CAM programming and additive manufacturing. The portfolio is so vast that it will pique your interest in everything machining from milling, turning, mill turning, or milling with a robot—just to name a few.

As so many are utilizing the convenience of a phone or other multi-media device, find out how our DELMIA applications will follow this trend, helping to increase efficiency, as well as other plans to make your job easier. Learn how DELMIA is pushing the envelope in terms of programming various types of machines, including offering the capability to manage laser water jet cutting or a wire EDM machine.

Discover more:

DELMIA Machining and Fabrication

Join the DELMIA Fabrication Community (for FREE)

Meet Our Speaker

Dominique Galmel

You can follow the DELMIA "Global Operations on the Go" podcast on Apple podcasts, Spotify, YouTube Podcasts, Deezer, by RSS or wherever you get your podcast

![]()

Take full advantage of knowledge management capabilities: Standardize, Elevate, Transform

Guest/Author: Dominique Galmel, DELMIA Fabrication Roles portfolio Director

Introducing Dominique Galmel

Therese (00:00):

Welcome to our DELMIA podcast, Global Operations on the Go. I'm your host, Therese Snow. Today our guest is Dominique Galmel, DELMIA Fabrication Roles portfolio Director. Welcome, Dominique!

Dominique (00:22):

Hello, Therese. I'm really glad to be here explaining about DELMIA Machining.

Therese (00:29):

Absolutely. So glad that you can make it today. So Dominique, before we get started, why don't you tell our listeners a little bit about yourself?

Dominique (00:39):

Okay, so am I'm quite a long time Dassault Systems employee, something like 20 years experience over here. Before that I worked for a small software company in the CAM domain already. So I joined Dassault Systemes as the solution manager for fabrication process engineering and then move for a while to the industrial equipment industry, taking care of machines of all kinds. And now we're back to DELMIA for the fabrication wholes portfolio director in charge of the machining and additive portfolio.

Discover CAM and Fabrication Solutions

Therese (01:18):

That sounds fantastic. So it sounds like we're going to have so much to discuss today as you're an expert in that field. I think that the best way to go forward in this discussion is to have you explain the Dassault Systemes solution for CAM (Computer Aided Manufacturing) and fabrication in general.

Dominique (01:36):

Yes, absolutely. Fabrication is the domain that we are using at DELMIA to organize our portfolio, which is quite wide. It is composed of two sections to major lines of products dealing with the machining CAM programming and the additive manufacturing topic. Machining is quite a complete wide solution. We do milling, we do turning, we do mill turn, we do milling also with a robot, which is becoming really important for the industry. But we go a little bit further in terms of programming any kind of machines with capability to manage laser water jet cutting. Also a wire E D M (Electrical discharge machine). Overall, the goal of the solution is to provide a kind of a virtual workshop for the NC programmer with the path the machine tooling and any kind of tools, let's say, to do programming in this context. And of course with the realistic simulation that we can provide.

(02:45):

In addition, we need to generate NC code and we also provide post-processing capabilities in the machining portfolio. And the solution relies on our 3DEXPERIENCE platform, which is a collaborative environment enabling very nice collaboration as well as safety and security for the data. So that's for the machining part.

For additive manufacturing, we have started a few years ago now historically to cover metal part production with ED techniques or technology that we are covering. But now we are also covering some new processes, especially to produce polymer parts. In addition, we also have the capability for metal deposition and that that's as those applications for additive or machining are relying on the same infrastructure. This is again our platform to provide our customers a common environment to develop products or to program parts, those different capability that we are fully compatible. So we can mix within a single process, additive machining wire, E D M and all that kind of technology we are carrying more or less this is what we are doing for the machining portfolio.

The CAM Market Evolution

Therese (04:10):

No absolutely sounds really fascinating. Dominique, can you explain a little bit what is Dassault Systemes vision for the CAM market evolution?

Dominique (04:21):

Yes, the vision today, what we're seeing, especially in the CAM market, which is becoming quite a mature environment, we see, especially in Western countries, most of the people that have the knowledge retiring. So it's an issue for those company to be sure that the next generation of people will be able to produce parts as efficient as it was in the past. So we'll come back later in the discussion I think on the optimization, but this is a really important topic for us to enable the management of knowledge to help those users to those new users, let's say, to continue to program as efficiently as the previous generation was doing. In parallel to that, we'll also work on the automation and in also simplification of the user interface to be sure that those new users will be able to work as efficient as they can in this complex environment. And also I think the way users are now expecting software to work is a little bit different. We are all used to use our own phone device or all that kind of media. Modern media and our application should also follow this trend, allowing any kind of users to be efficient.

Dominique (06:20):

So in the future also we believe that having artificial intelligence embedded into our application will allow us to provide advice, let's say to do some kind of a generative programming for those new users based also on the knowledge that experts will have put into the system. And this is really where we want to go in this vision of the CAM market.

Optimization in the CAM domain

Therese (06:56):

I think those are really good points and an excellent vision. AI I think is really taking over so many areas, so I'm happy to see that this is a part of that. So what are the possible optimizations that you see in the CAM domain?

Dominique (07:12):

Well, I think this is really important to have it in mind. There is different ways of declining this optimization. I think we talked about it a little bit earlier within the vision. I think this is the most important we can say today. And being able to capitalize on the knowledge of the company, trying to store all those kind of best practice we can say, and we call it some kind of a machining template that can be reused across the different products and parts, leveraging all the necessary parameters for cutting tools and the appropriate cutting tools for a given operation. So that will really optimize at the hand the result on the machine stabilizing, let's say the different programs, whatever the programmer will be. As we talked about it, there is a challenge on this population, which is retiring. So this is really important that we can reuse this knowledge where to optimize the creation of the toolpath then it's not the only point.

(08:34):

We need also to optimize on the machine. This is really, really important. And to do that we are working really close with cutting tool makers, trying to increase the capability of our tool path to be more compatible, let's say with the performance of the tools, developing eventually some specific tool paths like in turning application for example with some leaders in terms of cutting tool vendors. So that's the second aspect, really optimized on the machine because at the end the cost for production will be on the machine itself with the reduction of the machining time that we can expect. But also stop here, we'll stop here. I will not add anything from there.

Therese (09:32):

Well that sounds really interesting, Dominique. Some very good points you made in the vision optimization. It was very clear. So thank you so much for taking the time to speak with me today. Yes,

Dominique (09:51):

I hope our audience will be happy to listen to us. And of course if there's more question that needs to be taken, I'm here to answer whatever the channel. Thank you. The

Therese (10:08):

Oh, my pleasure. Absolutely. And for our listeners' sake, I will go ahead and be putting some information at the bottom of this podcast should they have any questions, they'll have a way to contact us. So thank you to our listeners for tuning in. I'm your host THERESE Snow, and you've been listening to DELMIA's s Podcast, Global Operations on the Go!.