Key Skills for Sustainable Innovation in Manufacturing Revealed in Study from Dassault Systèmes

Listen to this press release

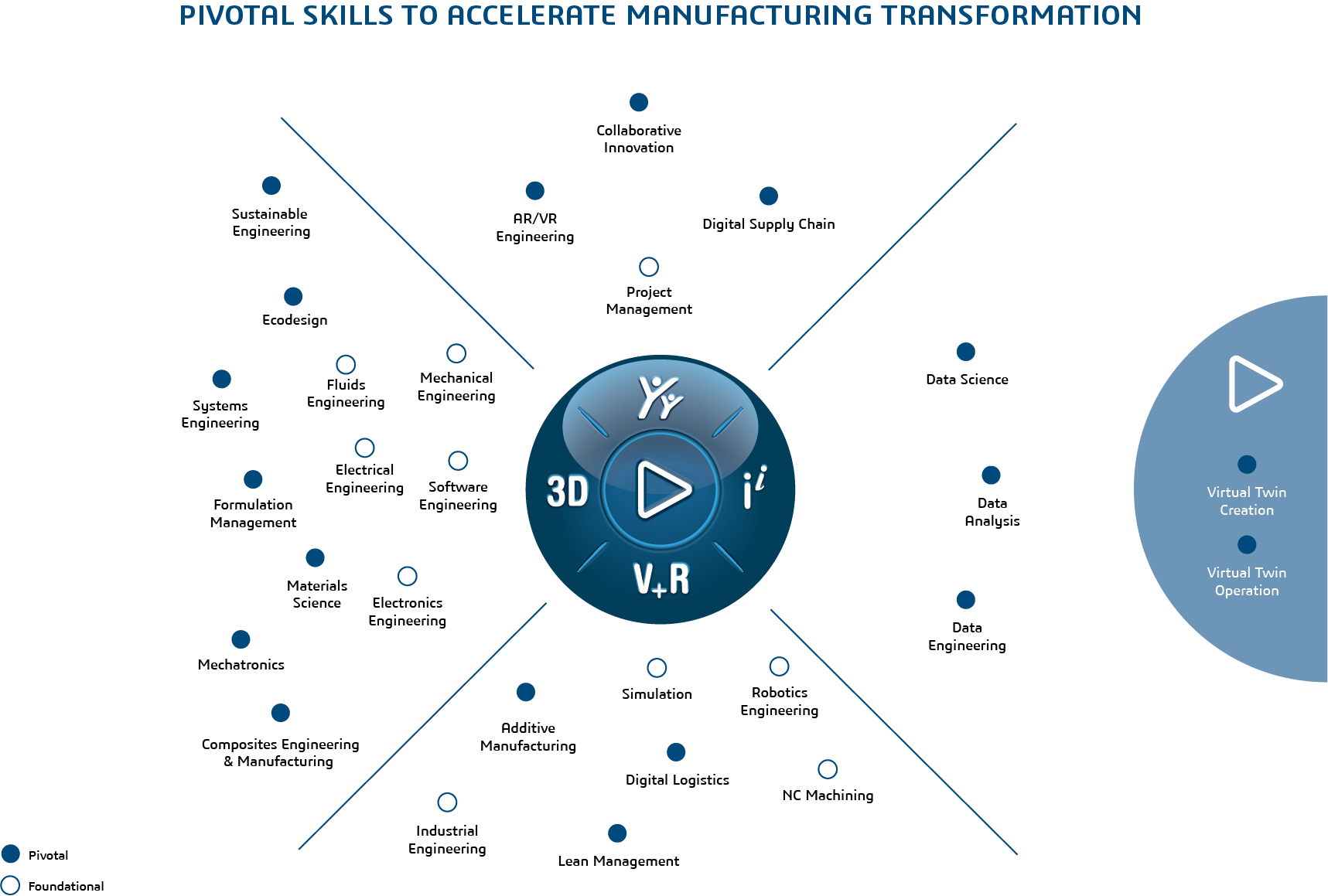

- Design for sustainability, mechatronics, additive manufacturing, data science and model-based systems engineering are core or emerging areas of opportunity for accelerating the manufacturing sector’s transformation

- The insights were revealed in a one-year analysis of social media discussions on manufacturing skills and disciplines, commissioned by Dassault Systèmes’ 3DEXPERIENCE Edu and conducted by Bloom

- Dassault Systèmes, with 40 years of industrial expertise, federates its ecosystem to prepare the workforce of the future for new and evolving jobs

VELIZY-VILLACOUBLAY, France — September 29, 2022 — Dassault Systèmes (Euronext Paris: FR0014003TT8, DSY.PA) today revealed key skills to accelerate the manufacturing sector’s transformation to create sustainable experiences. Design for sustainability, mechatronics, additive manufacturing, data science and model-based systems engineering are among the core and emerging areas presenting opportunities for industry and academia to prepare the workforce of the future for new and evolving jobs in the sector.

The findings came from an analysis of social media activity that was commissioned by Dassault Systèmes’ 3DEXPERIENCE Edu. The aim was to provide insights on how manufacturing skills are discussed, and to empower its ecosystem to reduce the skills gap in a sector that accounts for 41% of global GDP and whose transformation presents a major opportunity for minimizing impacts on the environment and creating more sustainable systems. For 40 years, Dassault Systèmes has been the catalyst and enabler of unparalleled industrial innovation, connecting and strengthening the efforts of industry and academia to collaboratively nurture the continuous learning environments needed to deliver innovations that improve quality of life for consumers, citizens and patients.

Findings from the analysis of discussions about the manufacturing sector include:

- Design for sustainability is becoming part of the everyday day conversation from consumers to companies, with academic institutions trying to become leaders in this space by featuring short programs and informational lectures.

- Mechatronics has the most active community on social media with more emotion and engagement than all other skills combined, revealing how technical topics can be highlighted primarily through videos or other engaging formats to attract a younger audience.

- Additive Manufacturing accounted for 55,100 discussions with more than 278,000 engagements in English, dominated by companies and universities around academic publications, new innovative usage methods, ongoing projects and promotional corporate material.

- Data science is primarily discussed at a high level focused on industry certifications or open positions offered for data scientists. Few universities and companies talk about this skill on social media, although it is critical for their future business.

- Few actors or communities are engaging on the topic of Model-based System Engineering, revealing opportunities to increase conversations and awareness of such a critical discipline for the future of many industries.

“We launched this study to get a glimpse into the discussions trending on social media across a diverse horizon of stakeholders: students, teachers, businesses, experts and others. With this insight, we can federate our ecosystem to help prepare students and the workforce to work efficiently, collaboratively and productively to solve major sustainability challenges,” said Florence Verzelen, Executive Vice President, Industry, Marketing & Sustainability, Dassault Systèmes.

In addition to this analysis, Dassault Systèmes is taking action to develop the skills required to transform the development of products into the development of sustainable experiences within its ecosystem of schools, training organizations and customers through multiple channels such as a series of e-books on skills and an online academic community where experts share best practices.

These channels also include the 3DEXPERIENCE Edu Centers of Excellence global program, which accelerates experiential lifelong learning by providing businesses and governments with a network of centers to develop the 3DEXPERIENCE platform expertise needed for the digital transformation of industry. The program now counts 11 members, most recently: Instituto Maua de Tecnologia, a private non-profit technical university in Brazil; L’Industreet, a technical college in France to provide young people who have left school with training in the field of industry of the future; ZHAW, a university of applied sciences in Switzerland; and Trier University of Applied Sciences, in Germany.

“We offer our learners multiple opportunities to consider the broad context of engineering. Central in such a context is the imperative of design for sustainability,” said Michael Hoffmann, Director of the Laboratory for product development & manufacturing, Trier University of Applied Sciences. “Minimizing material and energy consumption, enabling the use of biomaterials and optimizing the lifecycle with a virtual twin are some of the methods we promote and the 3DEXPERIENCE provides countless opportunities to develop the competencies required, for our students and our industry partners as well.”

About Dassault Systèmes

Dassault Systèmes is a catalyst for human progress. Since 1981, the company has pioneered virtual worlds to improve real life for consumers, patients and citizens. With Dassault Systèmes’ 3DEXPERIENCE platform, 370,000 customers of all sizes, in all industries, can collaborate, imagine and create sustainable innovations that drive meaningful impact. For more information, visit: https://www.3ds.com