As demand for deliveries rockets, how can we make packaging more sustainable?

Customers everywhere are demanding more sustainable packaging solutions. Catering to this demand is not just good for the environment – it’s good business as well.

The world’s use of packaging is surging. As demand for home-delivered goods continues to rapidly rise, intensified by the COVID-19 pandemic, so does the need for more packaging. Consumer goods shopping via ecommerce grew 41% in the first half of 2020 alone. But along with items that might traditionally have been bought on the high street, like clothes or books, there has also been a significant increase in items like groceries and ready-to-eat food, all of which come in a bag or a box.

For manufacturers and packaging businesses this creates a problem – how can they balance our insatiable demand for deliveries with the need to make packaging more sustainable?

Sustainable packaging is not just an environmental demand from governments or activists, it is a consumer demand – and one which people are willing to pay for. According to one study, 66% of global consumers are willing to pay more for sustainable goods, and a full 73% of millennials are. As a result, the value of the global sustainable packaging market is expected to hit $255 billion by 2026. It has therefore become essential that consumer packaged goods (CPG) companies find innovative ways to reduce the environmental impact and ecological footprint of packaging.

Why You Must Act Now

To start with we need to understand what is meant by sustainable packaging. What type of packaging is environmentally friendly? This is more than just revaluating the materials used, it is about understanding the lifecycle of both the product and its packaging, of what happens after consumers open and discard a paper or plastic package.

Virtual twin solutions could help the CPG sector save in product development, material costs and CO2 emissions

Design decisions can be linked to 80% of a product’s environmental impact, so there are major opportunities in rethinking what is sustainable packaging design. Plastics pose a particular problem. Single-use packaging that is quickly discarded accounts for 40% of plastic and less than 20% of it is recycled globally, so developing cleaner, more sustainable alternatives is crucial.

Bioplastics, for example, can deliver the same performance of virgin plastics, but avoid their environmental pitfalls. They can be produced from cellulose or lignin or obtained from non-food plants like giant reed.

However, if these plastic alternatives are to go to market, then knowing how new materials impact product performance is vital. Many packaged products, developed with the best intentions, fail to reach shelves thanks to inadequate testing and validation processes.

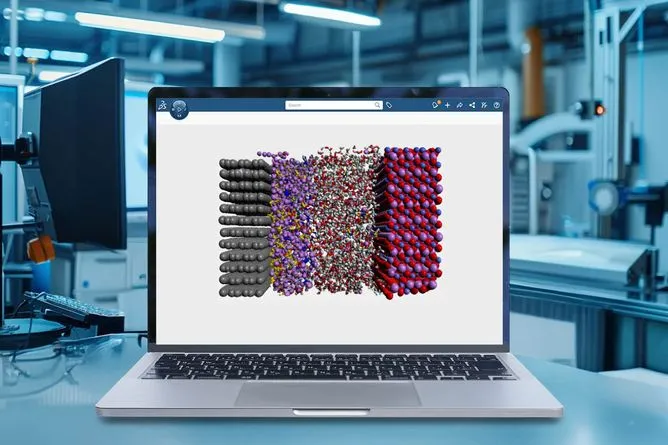

This is where digital solutions can help turn sustainable ideas into reality. With 3DEXPERIENCE® cloud-based virtual twin solutions, for example, manufacturers can digitally validate how products perform under a range of real-world variables, replicating the properties of new materials down to the molecular level.

Virtual twins can help designers check whether new plastics will react with the substances they contain; or whether new molds will be needed in factories; or whether their material tolerances will withstand the pressure when items are stacked on top of each other for transit. All this helps manufacturers get sustainable products to market faster and reduces the need for prototyping.

All told, it is estimated that virtual twin solutions could help the CPG sector save $6 billion in product development and $131 billion in material costs, and could help it avoid 281 million tons of CO2 emissions .

To integrate these new materials into the process, manufacturers need to be able to understand, design and test them through digital simulations. The Perfect Package solution allows manufacturers to design sustainability-optimized products, and test those products in simulations to see how they behave at each stage of the product life cycle.

Rethink your packaging with the cloud

Learn how cloud-based digital solutions can help you develop, test, and integrate sustainable packaging solutions across the supply chain

Build a circular economy

Sustainable packaging is as much about recyclability and reuse as it is about reducing material usage and waste. It is a whole system approach that is built on the principles of circular economy.

Achieving this requires involvement from every step of the value chain to ensure systems are in place that allow for packaging to be broken down into its original components and sent back to be reused as packaging again.

And once again, digital solutions enable these ideas to become a reality. The Holy Grail project, a collaboration between more than 80 European CPG companies, is an example of this in action.

The project aims to fit consumer plastics packaging with a small “digital watermark” the size of postal stamp. When this is passed in front of a high-definition camera in a recycling facility, this watermark allows operators to precisely identify the plastic in question, allowing it to be more accurately sorted, and overall recycling efficiency improved.

The cloud-based 3DEXPERIENCE platform can powerfully augment these kinds of approaches by giving multiple stakeholders a single source of truth from which they can work from. This enables them to collaborate and innovate on new products and processes and then track them throughout their whole life cycle, from design to disposal.

Change at pace

Transforming packaging systems for sustainability is a matter of urgency, as pressure from both consumers and new government regulations and targets come to bear. However, responding and innovating with speed is challenging when many manufacturers are still relying on traditional processes and legacy systems that result in an inability to bring new ideas to market quickly and effectively. A fully efficient circular system requires all stakeholders to have visibility into processes, not just the manufacturer.

End-to-end digital transformation is therefore essential in having an umbrella view of the current manufacturing operations, what potential bottlenecks might arise, and which processes could be best improved to best integrate a more sustainable approach.

3DEXPERIENCE’s virtual twin solutions can help here too, enabling multiple stakeholders to model and test the potential impact of their innovation. From helping refine the design and development of new consumer product packaging to making sure supply chain operators can optimize behaviors right across the product lifecycle, improving workflow and reducing waste.

It can also help them see how multiple parts of the supply chain interact. For example, while a manufacturer may be changing one plastic for another for recyclability reasons, full visibility over supply chain operations could also let them see how altered designs affect the weight of units, and how this could impact fuel efficiency.

Bringing truly sustainable backpacking solutions to market requires a holistic approach. Through a cloud-based digital platform, consumer packaged goods (CPG) companies and manufacturers can work together to turn their ideas into reality and deliver truly circular, low-waste approaches to product development and delivery.

Top articles on Sustainable Manufacturing

Explore our Industry Solution Experiences

Learn more about how our industry solutions can help you to achieve your professional ambition and business objectives

6 Steps to Smart, Efficient Tires

Ready to unlock speed and precision in tire development? Here’s how to achieve it with our integrated platform.

- Accelerate Materials Innovation

- Model and Simulate From the Start

- Maximize Production Efficiency

- Foster End-To-End Collaboration

- Ensure Digital Continuity

- Embrace Sustainability

80% of tire innovation stems from materials. Predict and optimize existing tire formulations through platform-driven simulation and collaborative material management to develop new, sustainable materials quickly and precisely.

Shorten design cycles by integrating multiple design factors into virtual prototypes from the start. Optimize the ‘Magic Triangle’ and reduce the need for check tires by up to 85% through modeling and simulation.

Streamline operations to improve plant availability and boost productivity. Integrate 3D design and simulation to optimize processes — reducing development and testing time by up to 25%.

Incorporate data from all stakeholders for a seamless and integrated tire development process. Real-time collaboration improves communication, reduces supply chain disruptions and optimizes manufacturing operations.

End-to-end digital continuity shortens the testing and evaluation process from weeks to hours. This single source of truth boosts right-first-time rates, speeds up time to market and aligns every development phase to business objectives and customer demands.

Embed sustainable practices throughout the tire development lifecycle. Optimize resource and energy use, minimize waste and reduce greenhouse gas emissions to meet regulatory standards for a sustainable future in tire development.