Agile Mass Customization Is a Must With No Ifs, Ands or Buts

Manufacturers must leverage end-to-end visibility and attain production agility to meet mass customization challenges head on.

"You can have any color you want, as long as it's black," Henry Ford once said. The industrial revolution has come a long way since the Ford Motor Company founder uttered this famous line and went on to develop the assembly line technique to mass-produce identical cars in 1913. Today, the manufacturing world sees a distinct shift from mass production to customized production. Customers are now better informed and want products tailored to their preferences.

With more than 50 percent of customers keen on purchasing customized products, it's not an option but a necessity to adopt an agile mass customization strategy to stay competitive. However, it’s challenging to juggle diverse portfolios, deliver more variants and maintain speed to market without end-to-end visibility that drives efficiency at every step. This is where an integrated platform can help build agility without compromising efficiency, cost or quality. Download our ebook to find out more.

The Rules of the Game for Agile Mass Customization

A well-implemented agile mass customization strategy allows manufacturers to create value-added products while maintaining economy of scale. However, to remain competitive, manufacturers must shift to new approaches that are customizable, highly flexible and resource-efficient.

Manufacture on the Cloud

Until recently, manufacturers had to circumvent manual processes and legacy systems that offered limited flexibility, scalability, integration and visibility.

With agile mass customization, manufacturers can incorporate an on-demand manufacturing model that leverages an online ecosystem to support production from floor to door. By connecting creators to partners and providers on the cloud, it becomes easier to get instant quotes, transact globally, manage projects and track inventory from any browser at any time.

Waste Not, Want Not

Waste production is increasing worldwide, with a projected 70 percent increase over the next 30 years. Despite bringing economy of scale to the table, mass production also contributes to high energy waste. A study revealed that 20 percent of shoes produced worldwide annually are never sold. Unsold products that do not meet market demands are disposed of, representing wastage in material, time, equipment use and inventory.

On the other hand, agile mass customization is epitomized by resource efficiency and flexible processes. By accurately forecasting demand, manufacturers reduce waste and avoid having excess inventory, overloading assembly lines and factory space. Agile mass customization also supports overall waste reduction through lean global operations and supply chain processes.

Small Batches for a Big Payoff

Small batch production is a key component that accelerates the shift to agile mass customization. The transition to this model requires an integrated cloud platform that enables collaboration across multiple project teams and timelines.

Developing goods in small batches at cost and scale allows manufacturers the flexibility to maximize resources. They can also execute concurrent production processes and multiple parallel activities that feed into a final assembly stage.

Besides manufacturing more diverse products with shorter life cycles, small batch production offers payoffs in cost control, new product testing, production scale-up and waste reduction.

Quality Is Never an Accident

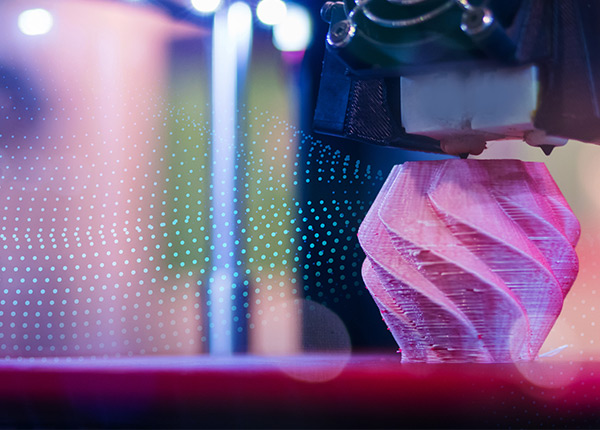

The advantage of implementing an agile mass customization strategy is evident in product development. By using advanced 3D design capabilities that drive agility, manufacturers can optimize product design, speed up design iterations, accelerate product launches and deliver customized, high-quality products to the market.

In addition, manufacturers can use a virtual twin-enabled platform to:

- Optimize customized products' manufacturing without physical prototypes

- Better manage process disruptions

- Swiftly effect changes to meet individual market demands

Mass customization is a global trend because the market demands it. This goes beyond addressing market segments and niches. It's about acknowledging that every customer is an individual market.

Agile Mass Customization Powered by the 3DEXPERIENCE Platform

The ability to flexibly meet ever-changing customer preferences is central to mass customization success.

Here's where Dassault Systèmes' cloud-based 3DEXPERIENCE® platform comes in. The platform allows manufacturers to implement an agile approach powered by real-time information visibility that covers procurement, logistics, accounting, merchandising, sales, production planning and supply chains.

By connecting information and people on the platform, stakeholders can collaborate effectively. This allows manufacturers to:

- Identify and solve issues to continuously improve processes

- Adjust operations on demand

- Reorganize production lines to serve individual customer needs

With the 3DEXPERIENCE platform, manufacturers can successfully transition to a future-proof agile mass customization strategy.

Read our top articles on Future Proof Systems

Explore our Industry Solution Experiences

Learn more about how our industry solutions can help you to achieve your professional ambition and business objectives