Achieving Sustainability With Additive Manufacturing

Sustainable manufacturing has become critical in securing a competitive advantage. Discover what’s in it for manufacturers and how they can shift to this new manufacturing technique seamlessly.

Sustainability as a Business Strategy

With growing public pressure for manufacturers to introduce more visibility into their products’ sourcing and production processes, sustainability is no longer a long-term goal but a strategic imperative. Manufacturers must also pay close attention to the total energy consumption, supply chain requirement and overall environmental impact of their products.

This is where additive manufacturing (AM) can play a crucial role. By leveraging AM on the 3DEXPERIENCE® platform, manufacturers can consistently deliver products that consume less material, produce less waste, cost less and function better than their conventional counterparts.

Plan to Succeed, Execute to Win

Additive manufacturing (AM) offers many benefits. Find out how manufacturers can successfully execute AM initiatives and avoid potential pitfalls.

How Additive Manufacturing Further Enables Sustainability

Manufacturers seeking to become more sustainable can do so by reducing their inventory, lowering energy consumption and lessening transportation requirements.

Let’s have a closer look at the broad range of sustainability benefits that can be derived through AM:

- Less material waste

- Carbon footprint reduction

- Lighter, more efficient parts

- Mass personalization

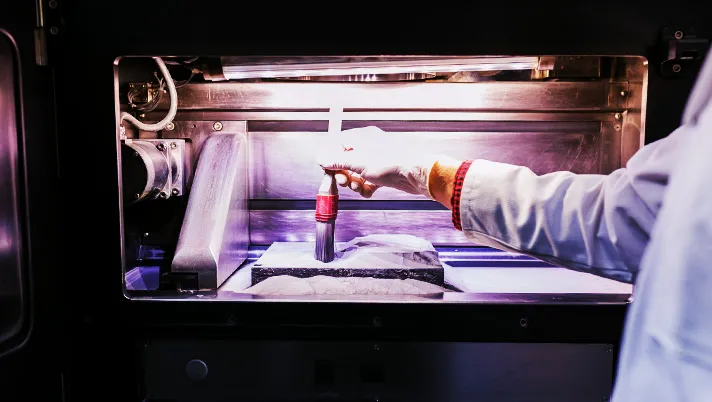

Less material waste

Manufacturers can develop optimized design dimensions that minimize waste and reduce energy consumption. Parts can be created entirely bespoke to suit customer needs and avoid wasteful large-batch production. With AM, raw materials can be recycled or converted into AM-grade powder, reducing storage space while raising material value.

Carbon footprint reduction

When parts are made in-house instead of imported, manufacturing carbon emissions are reduced as less material usage and transportation are needed. Complex parts can also be printed in one piece, eliminating the need to produce multiple parts that are assembled later. This significantly minimizes factory on-time and transportation requirements.

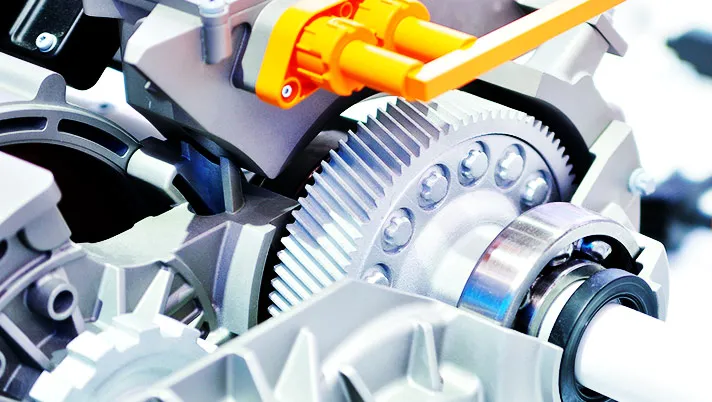

Lighter, more efficient parts

Weight reduction is a constant key issue, driven both by fuel cost and carbon footprint. By utilizing AM technologies, vehicle manufacturers can develop lighter, more fuel-efficient vehicles through innovative design features. In the aerospace sector, weight reduction from AM processes can result in energy savings of up to 25%. Additionally, each kilogram of weight loss on a flight can save up to US$3,000 in fuel annually.

Mass personalization

With AM, manufacturers can offer more variations on a given product without additional tooling or other infrastructure investment. Sufficient input data, paired with software manipulation, can be converted into a file that’s ready to be used for AM. Manufacturers can combine this information with customer input to produce a range of personalized items.

Additive Manufacturing Powered By the 3DEXPERIENCE Platform

AM supports ongoing product development and flexible changes that empower product stakeholders to arrive at better products more quickly. The right digital business platform can significantly speed up this process. Dassault Systèmes’ 3DEXPERIENCE platform enables manufacturers to seamlessly merge design, simulation and manufacturing. This creates new product development opportunities:

Production cost

Anticipate the cost of parts production while taking into account print speed, the number of parts printed and the size of printable parts.

Traceability

Digitally model components and parts within a single virtual environment for greater accountability and traceability between stakeholders and reduced intellectual property counterfeiting.

Quality control

Ensure parts are made of high-quality materials through better control of manufacturing parameters.

The 3DEXPERIENCE platform helps manufacturers visualize their machines working together with materials, and enables them to calculate the right parameters for production. This information can then be shared across the enterprise, allowing for reliable and trustworthy operating wherever the component is printed.

Sustainability will soon become a core tenet of manufacturing, thanks to more powerful and less expensive AM technologies. By utilizing solutions that cover the full breadth of AM processes built right into the 3DEXPERIENCE platform, manufacturers can implement and enjoy the full benefits of sustainable manufacturing with minimal impact to their product development workflows.

Read our top articles on Future Proof Systems

Explore our Industry Solution Experiences

Learn more about how our industry solutions can help you to achieve your professional ambition and business objectives