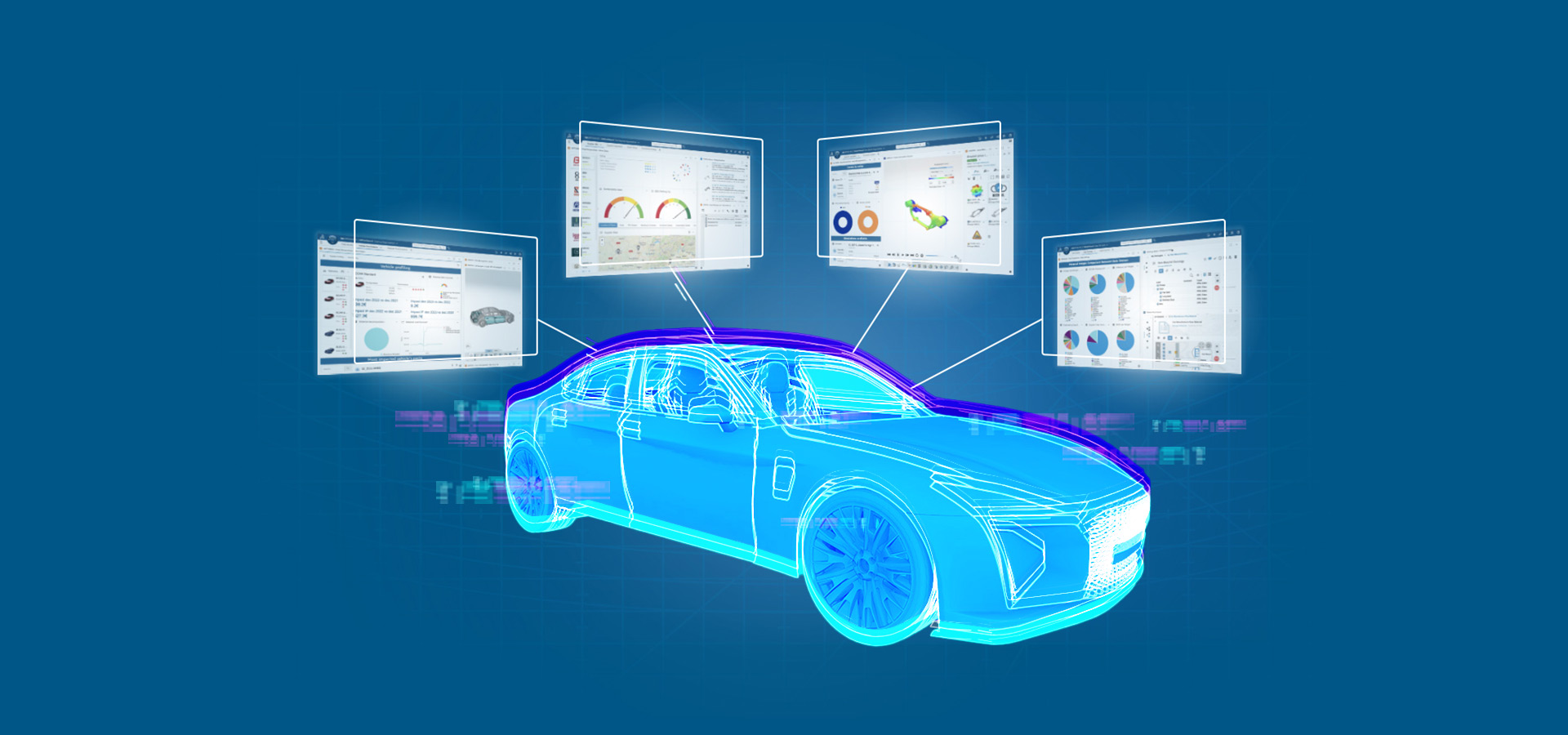

Laurence Montanari: Yes, for sure. So, the first example we have currently is with a French carmaker. We started with the virtual twin of their product but now we are moving to the virtual twin of their company. And the supply chain is important because it's an important virtual twin in order to manage the supply chain and to be sure that you have the right parts at the right moment in the production, at the right price. This is because cost is very important in mass production in the automotive sector. So, we started from the virtual twin of their supply chain, and we are able to manage risk.

In this model, we have real data. So, what is the increase in cost if the currency or the inflation rate changes? What are the impacts on the vehicle and its margin if there are shortages of metals or parts? We can support them in anticipating and better managing all those risks because these risks in the supply chain are real.

Morgan Zimmermann: I think it's a very interesting example. Very interesting because it's not obvious for everyone in the industry to see Dassault Systèmes modeling the supply chain. But in the example that you mentioned, the only single reason why we are the most legitimate in doing it is because we can match the supply chain to the vehicle to be manufactured. And because we are capable of matching that supply chain to the product to be manufactured, we are indeed capable of anticipating on each and every single configuration what the impact of an event in the industry is, whether shortages or cost improvements. Because we can do it on the vehicle and we can do it on the production so we can understand what's the impact on the entire budget of the company.

Laurence Montanari: Exactly.

Morgan Zimmermann: And this ability to mix and match the virtual twin of the product with the virtual twin of the supply chain, with the virtual twin of the enterprise, I believe, is putting us in a very unique position to transform and support the transformation of this industry.

Laurence Montanari: Yes. It's true. But it's not the only one. Let's speak about the standardization of parts, for example. Do you know how many parts are in the warehouses of carmakers in order to make repairs?

Morgan Zimmermann: I have actually no idea.

Laurence Montanari: Okay. So the minimum is 200,000 parts. So imagine that your car is coming to the dealer. So, imagine the dealer does not have your part; it's not possible. So, standardization is the way to be sure that the dealer will be able to repair cars in an efficient way and give your car back at the end of the day. So, the standardization of parts is a very important example.

Morgan Zimmermann: I agree. And by the way, that leads to two reactions from me. Reaction number one is, if I look at our portfolio, we already have a pretty large portfolio of industry process experiences in the automotive industry for planning optimization and vehicle program optimization with data on cost, LCA or value network optimization. But there is probably another area where we could learn from aerospace. In aerospace, we have used virtual twin experiences to enhance the quality and availability of fleet in operations. And of course, this is only for thousands of aircraft or tens of thousands of aircraft.

But in my dream, why don't we use virtual twin experiences in the automotive industry for millions of cars to serve exactly the problems that you just anticipated?

Laurence Montanari: Yes, it's a good idea. And clearly, there is industry cross-fertilization. We need to take the example of aerospace and defense, which is advanced in the maintenance of aircraft.

Morgan Zimmermann: Thank you very much, Laurence. I think not only do we already have a great portfolio in the automotive industry, but we can extend it and go into after-sales and operations. A bright future in front of us. Thank you again for your commitment to virtual twin experience and data-driven virtual twin experience.

Laurence Montanari: Thank you, Morgan. Thank you, all of you.

Narrator: Disruptors Unleashed is produced by Dassault Systèmes. For more episodes, follow us on Apple Podcasts, Spotify, Deezer or your nearest streaming platforms. To learn more about Dassault Systèmes, visit us at 3ds.com.