Zhaw

ZHAW School of Engineering provides theoretical and practical training on CATIA for multi-disciplinary systems design and documentation, ENOVIA for collaboration, DELMIA for manufacturing simulation and robotics, and 3DEXCITE for high-end 3D visualization.

CULTIVATING STUDENTS’ PIONEERING SPIRIT

Providing its students with a window into the future by making technology a cornerstone of its academic approach has enabled Switzerland’s ZHAW University of Applied Sciences to instill in them a forward-thinking and pioneering spirit. “At ZHAW’s School of Engineering, our goal is to teach our students the latest technologies and methodologies and how to apply them in a professional context,” Peter Hug, dipl.Ing. FH, lecturer, ZHAW school of engineering said. “Engineering students who graduate mastering the latest technologies are more likely to influence the industry by taking initiative thanks to their creativity and innovative approach. For example, there are many mid-sized companies in Switzerland that don’t use all the technologies our students have at their disposal. So when they do their professional internships, they can promote these technologies and inspire companies to use them as well.”

ZHAW proposes bachelors’ and masters’ programs in engineering as well as other areas such as life sciences, law, psychology, management and social work. “Our three-year bachelor’s program for mechanical engineering, for example, is over 100 years old and is well-known for promoting excellence through a combination of theoretical training and professional internships,” Adrian Burri, head of mechanical engineering at ZHAW said. “Students have the possibility to study abroad thanks to different exchange programs established with many partner universities worldwide.”

PREPARED FOR EMPLOYMENT

In terms of career opportunities, many of ZHAW’s engineering students find jobs very shortly after graduation. “A variety of industries in Switzerland that include manufacturers of machine products, household appliances, railway systems and of course, watches are interested in hiring our students because they have the ability to think out of the box,” Burri said. “We also provide qualification or certification programs for professionals to update them on new methods and technologies. In this way, they are better prepared to handle the business challenges their companies face. One of our currently more popular courses, for example, is about additive manufacturing and 3D printing. Classes are already pretty much booked for the year. Moreover, we are now part of the Dassault Systèmes Academy Member Label, a label that designates academic institutions that have made tangible efforts in promoting the benefit of Dassault Systèmes’ tools for student employability and curriculum quality.”

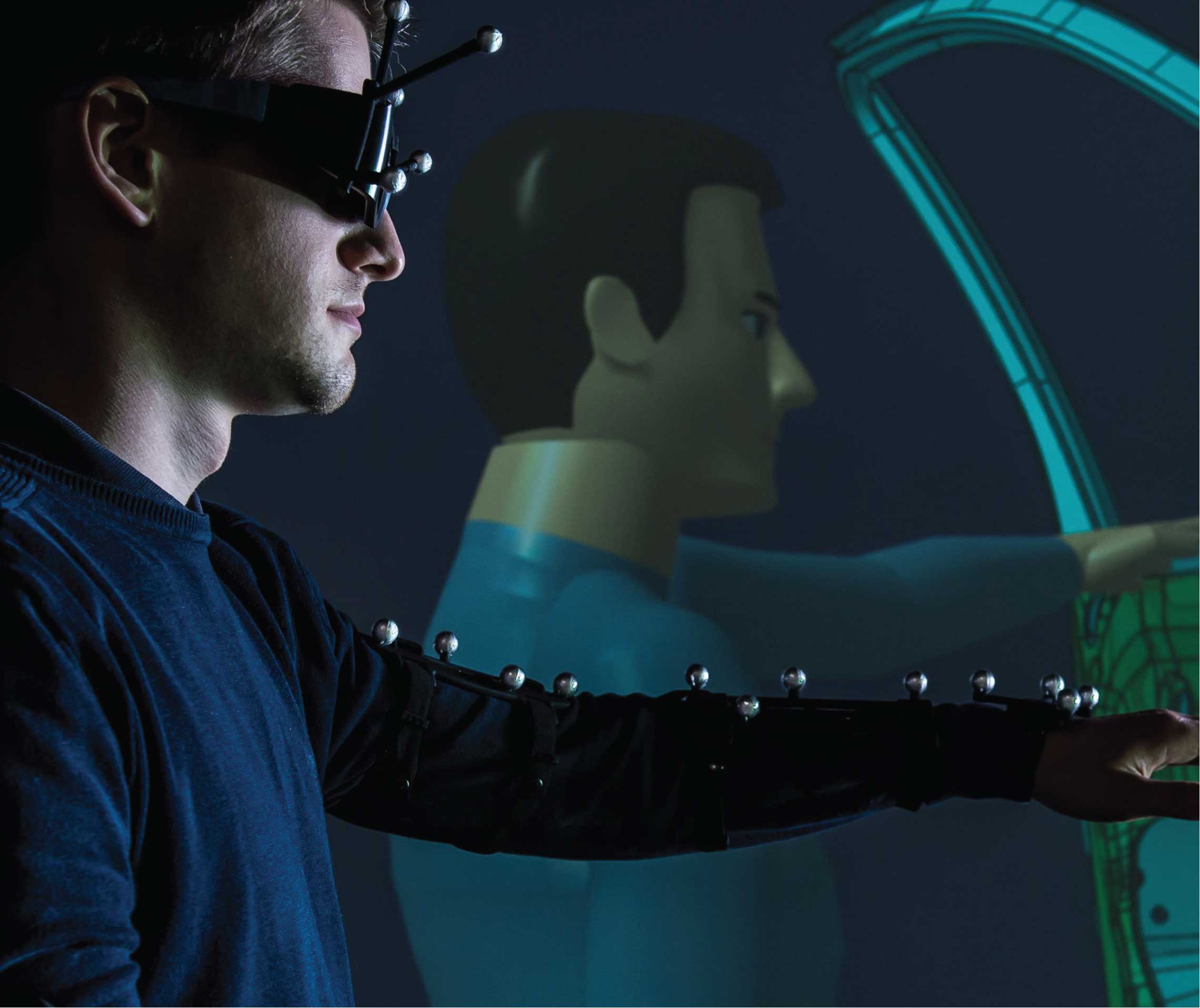

The Dassault Systèmes’ solutions have been a staple of ZHAW’s engineering curriculum for over a decade. More than 700 students in different engineering disciplines learn to use CATIA for multi-disciplinary systems design and documentation, ENOVIA for collaboration, DELMIA for manufacturing simulation and robotics, and 3DEXCITE for high-end 3D visualization. “We don’t only teach 3D modeling, we go further by integrating the notion of a company’s end-to-end process in the students’ training and how to best use the Dassault Systèmes solutions from design to manufacturing,” Hug said. “Understanding the entire product lifecycle facilitates their integration in a company because they speak the same language.”

The engineering school is often solicited to help students from other departments to realize their projects. One such project, initiated by the department of Facility Management, involved designing a hospital. “Our students used CATIA to generate the digital models, ENOVIA to manage project planning and DELMIA to perform maintenance simulations,” Burri said. Another example is in fashion where 3D is extremely popular with stylists and designers nowadays. “We use the Dassault Systèmes solutions to create a showroom in 3D, for example, or to reverse engineer accessories with our 3D laser scanning equipment. Once the digital model is generated, we can optimize the design before sending it to the shop floor, where the actual prototypes in plastic or metal are manufactured on our milling machines. Testing a model in a virtual environment helps us build a physical prototype right the first time.”

It is important to prepare our students for Industry 4.0 by incorporating the notion of multi-disciplinary collaboration in our classes. This is easy with the Dassault Systèmes solutions because different disciplines can work on a unique repository, which helps streamline and accelerate the development process.

4TH INDUSTRIAL REVOLUTION AND MULTI-DISCIPLINARY COLLABORATION

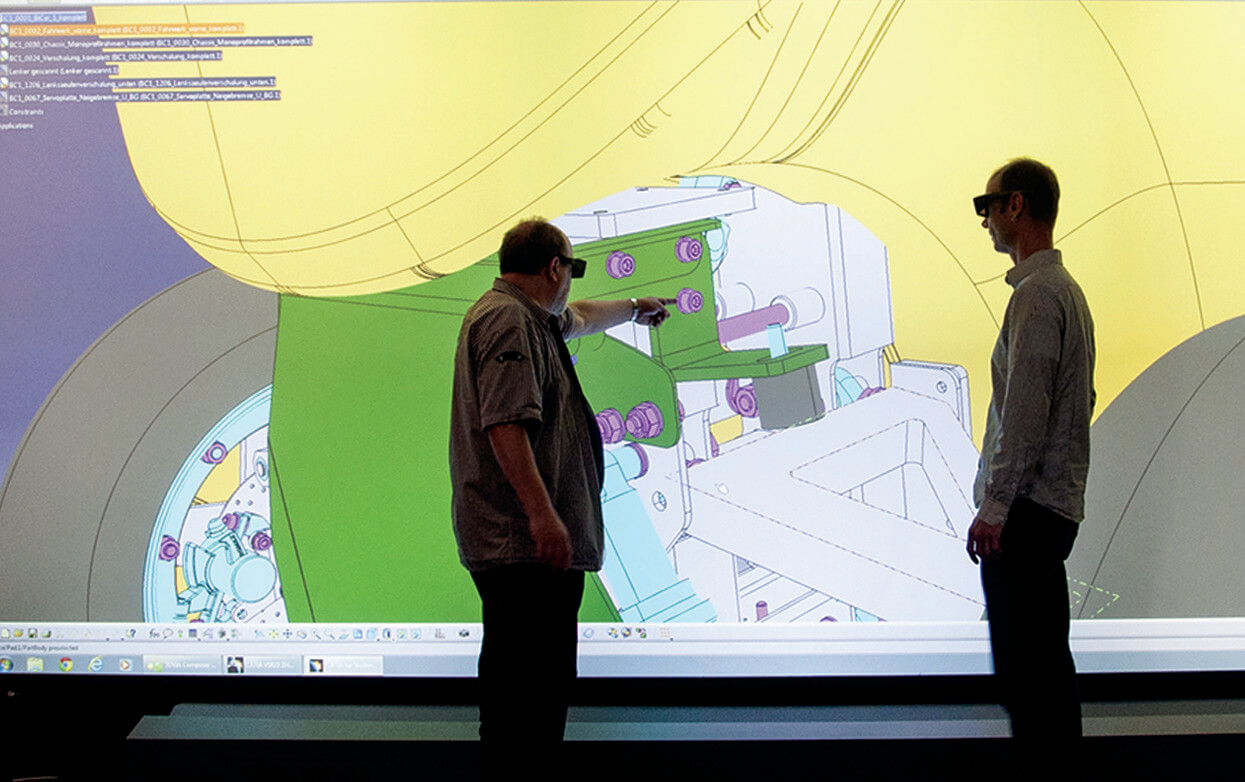

The design of any product calls for a multi-disciplinary approach involving different departments each with their specific expertise. Enabling electrical, structural, software and other disciplines to seamlessly work together on the same data facilitates decision-making and helps avoid errors that can drive costs and project schedules in the red. “The Fourth Industrial Revolution is upon us, where equipment and humans collaborate in real time,” Burri said. “It is important to prepare our students for Industry 4.0 by incorporating the notion of multi-disciplinary collaboration in our classes. This is easy with the Dassault Systèmes solutions, thanks to CATIA Systems in particular, because different disciplines can work on a unique repository, which helps streamline and accelerate the development process.”

In their final semester, students are required to complete a real-life project submitted by a company for their Bachelor’s thesis. “This is very motivating because students feel that they are really doing something useful,” Sascha Hänzi, lecturer, said. “There are roughly 30 professional projects per semester and 50 research projects every year,” Burri said. “For example, students designed and manufactured testing equipment for an electric car with CATIA to verify if the battery is charged. Another project that students were enthusiastic about was designing a set of headphones. CATIA’s Imagine and Shape application received rave reviews because of its powerful surfacing capabilities and the ability to manipulate the digital model as if it were a clay object. Students were able to try out many different forms in a very short amount of time and to virtually simulate using the headset. Finally, they applied high-end rendering to show-off their new design,” he said. Some students even use CATIA in their free time to design objects just for fun. “One of our students designed and simulated a robot opening an oven door, taking a chicken out and placing it on the counter. She was having fun but I don’t recommend using a robot to do this for real, it’s too dangerous,” Burri laughed.

A RESEARCH PLATFORM TO IMPROVE URBAN MOBILITY

Another subject that is attracting increasing interest today is sustainable mobility. ZHAW’s engineering students are currently designing the BICAR, a one-seater, electric urban vehicle that they hope to prototype by 2017. The idea behind the BICAR is to enable any citizen to use the vehicle to transport them over short-distances. “For example, if you come to a city by train and need to get to your hotel, which is one kilometer away, you can rent the BICAR to take you there. Once at the hotel, someone else can use the car to drive to their destination. The concept of sharing a vehicle is a very popular concept nowadays because it can help reduce pollution and traffic in our cities,” Burri said. “We plan to post our designs on a public research platform on the Internet to inspire other companies or research facilities to use them to come up with their own concepts and technologies,” Burri said.

The BICAR was entirely designed with the Dassault Systèmes’ solutions and ZHAW students continue to implement new ideas to their design. One is to include a weatherproof shell made of biodegradable wood fibers. “The BICAR project started out as a school project but has since grown into a collaborative effort between the school and 20 partner companies because we want to take the project to the next level by building a fleet of 20 BICARs to test them in the real world,” Burri said. “To promote our version of the BICAR to potential partners, we used Dassault Systèmes’ rendering technology to realistically illustrate the way the vehicle will look when finished,” Burri added. “We also used DELMIA to simulate a manikin in the car to verify its ergonomics before building a physical prototype. The virtual simulation tools helped us zero-in on the best design.”

Teachers at the engineering school are supported by CENIT, a Dassault Systèmes business partner that provides them with consulting, training and programming services. “CENIT is a very good partner; they develop our NC post processors, provide us with implementation support and even participate in our classes as guest speakers. Their knowledge of the Dassault Systèmes’ solutions is a valuable asset for our students,” Burri said.

The School of Engineering soon plans to transition to the 3DEXPERIENCE® platform to benefit from its unique environment and intuitive user interface. “Students learn using self-training and video lectures in addition to classroom training. Although they are also exposed to other software during their studies, they would learn faster if they had one solution and one user interface for all their design, analysis and manufacturing needs,” Burri said. The school also plans to instruct students on how to use the Dassault Systèmes solutions to incorporate manufacturing constraints in a design to verify its manufacturability before submitting it for production. “This would enable them to test, from the earliest stages of development, that the product can be manufactured, which is faster and less expensive than testing and redoing a physical prototype each time.”

Focus on ZHAW

Leading Swiss university of applied sciences.

Schools: Applied Linguistics; Applied Psychology; Architecture, Design and Civil Engineering; Engineering; Health Professions; Life Sciences and Facility Management; Management and Law; and Social Work.

Students: 10,234

Headquarters: Winterthur, Switzerland

For more information www.zhaw.ch/de/hochschule

Focus on CENIT

CENIT empowers sustainable digitalization. Our solutions are based on innovative technologies in product lifecycle management, the digital factory and enterprise information management. CENIT consultants provide customers with end-to-end advice to ensure that solutions are implemented with an understanding of the entire value chain. With a holistic approach and based on trusted partnerships, CENIT takes responsibility for solutions on behalf of our clients. CENIT has been helping prestigious customers in key industries to gain competitive advantages for over 30 years.

For more Information: http://www.cenit.com/