VLP+P

Italian engineering studio VLP+P provides technical assistance for complex surfaces, innovative steel structures and façades. They turned to the cloud-based Building Design for Fabrication industry solution on the 3DEXPERIENCE platform, giving all stakeholders simultaneous, real-time access to building data in the context of a 3D model.

Experts in complex architectural shapes

Rising boldly over the Marseille skyline, the head office tower for French shipping group CMA CGM is a dominant focal point for France’s second largest city. Designed by architect Zaha Hadid, the 147-meter-high tower stands out for its dramatic vertical geometry and striking glass outer façade, which sweeps and tapers down the building. On the south-east side, the glass windows curve and transform into the covering of the bridge to connect the tower with the adjacent building – a complex configuration of 2,700 different cells that mesh together perfectly.

This impressive feat of engineering was the work of VLP+P, an expert team of construction engineers specialized in engineering and design services for intricate steel structures and façades. The company, which has offices in Padova, Monaco and London, provided design assistance to define the geometry of the bridge and adapt the concept to meet construction requirements. Using CATIA, it developed a parametric 3D model that could adapt to each configuration and created the programming to quickly reproduce the models, construction tables and production data for each cell.

“We are the experts in very complex structures,” said Giovanni Patron, co-founder and partner at VLP+P. “Our business is one of the most skilled in the industry as we work with 3D models of façades. We’re very specific about what we do and are committed to being the best. As we’ve taken on larger and more complex projects, VLP+P has evolved into the company we are today, managing a group of 20 engineers and architects specialized in 3D modelling, as well as a team of structural engineers that take care of the thermal and steel calculations and façade claddings.”

VLP+P was founded on the belief that every architectural form, in spite of its complexity, has a constructive solution. The company’s goal is to manage this complexity and turn it into an orderly and achievable process, and help clients save costs along the way.

“Since the beginning, we have pushed the boundaries of innovation around our own ways of working to find new solutions to optimize the development of complex projects and buildings,” Patron said. “Our main focus is to reduce the time-consuming processes around project development. We combine the power of software with our expertise to handle the complexity. And as the cost of production goes up, we look for solutions to optimize production requirements, finding ways to reduce the weight of the structures and improve our processes and methods to solve new challenges.”

As the trend continues for spectacular high-rise buildings characterized by increasingly complex geometries, VLP+P’s role is to help bring these amazing structures to life.

“The next generation of designs are moving towards a search for new geometries, to create something that is even more challenging and beautiful,” Patron said. “When visiting a city, you’re drawn to and fascinated by the big buildings with strange geometries. We ask ourselves how it’s possible to build something like that. We want to make progress and be part of this exciting process.”

Committed to being the best at what it does, VLP+P needed an industry-leading technology platform to handle the increasingly complex projects it takes on. A user of CATIA design engineering software since it was founded, VLP+P found the 3DEXPERIENCE® platform on cloud a logical next step.

I’m sure change is happening. We’re learning to work in new, different ways and it’s leading to big changes. Here, the cloud definitely pays off; it’s the future.

Scaling up with the cloud

“We want to use the most advanced tools,” Patron said. “It was always in our mind to adopt the 3DEXPERIENCE platform to perform better and innovate our own way of working. These large projects require us to manage thousands of elements and the platform helps us to centralize and integrate all of our data and information.”

VLP+P worked with Dassault Systèmes partner and engineering specialist IDeCOM in Italy to implement the platform and learn how to take best advantage of it.

“They were the best partner for this role,” Patron said. “Not only do they speak the same language as us, but they work in the same field and can fully understand our needs. They could answer all our questions and find the solutions to our problems, helping us to take advantage of the platform’s rich functionality.”

Opting for a cloud implementation meant that VLP+P was able to get up and running on the 3DEXPERIENCE platform straight away without having to concern itself with the requirements of a physical IT infrastructure. It also will be able to scale its use of the platform with ease as its needs grow.

“We chose cloud because it doesn’t need a server configuration; it’s ready to use,” said Simone Lucangeli, co-founder and partner at VLP+P. “It’s the natural evolution in IT, constantly offering us new features and improvements. Once you’re used to having everything on the cloud and the convenience of accessing the latest 3D models and information you need with one click from any device, there’s no going back.”

Working in new ways

Backed by the 3DEXPERIENCE platform, VLP+P’s team of engineers is empowered to work more flexibly and interact with clients seamlessly.

“The cloud enables us to interact with our clients in more innovative ways and enable teams from different locations to work together with ease,” Patron said. “When we travel, we can still access all the latest models we need. And, of course, during the COVID-19 pandemic, when we were forced to work in isolation, we could still continue to operate with minimal impact on our productivity.”

Indeed, had VLP+P not implemented the 3DEXPERIENCE platform before the pandemic, information sharing would have been far more challenging.

“When we had to work from home from one day to the next, the platform was invaluable to us,” Lucangeli said. “It was as if we had the office in our laptop. The models we use are usually very heavy, they are gigabytes of memory, but with the platform we’re able to work on the same model from different locations at the same time. With the cloud we can download the models fast. We’ve been lucky to have this new technology.”

Just as the pandemic has been a catalyst for many businesses to rethink the future role of the traditional office and embrace remote working, VLP+P hopes that these changes also signal wider transformation within the construction industry. In the future, it expects to see more of its customers and partners take advantage of modern, cloud-based technologies.

“I’m sure change is happening,” Patron said. “People realize that being face to face isn’t the only answer anymore. With the sudden crisis, we’re learning to work in new, different ways and it’s leading to big changes. Here, the cloud definitely pays off; it’s the future.”

The software gives us the freedom to obtain the geometry and develop a strategy to optimize surfaces according to the technologies and materials we’re using.

Optimizing surfaces and geometries

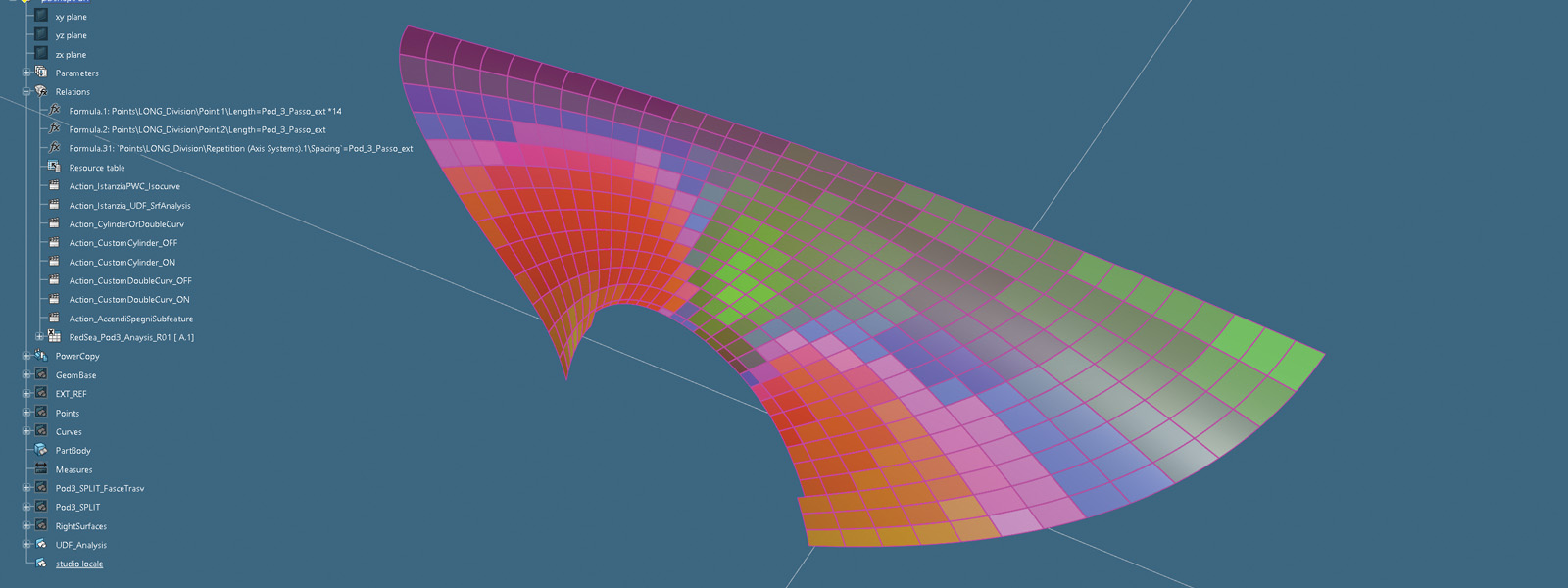

The intuitive and powerful modeling capabilities of CATIA on the 3DEXPERIENCE platform support VLP+P’s engineers to manage complex custom designs. It allows them to match the architect’s idea with the right production techniques without compromising on the aim and identity of the original project.

“Thanks to CATIA, we are able to translate the clients’ criteria, the principles and rules of the project, into a mathematical formula and relationships between elements that create and optimize the geometries,” Patron said. “For example, when we worked on the Europa building in Brussels, we optimized the double curvature glass with cylindrical ones, which are much cheaper and easier to produce. But the final shape of the cladding was exactly the same as designed by the architects. When working on other complex designs, we can optimize twisted geometries into simple cylindrical ones to bring costs down, without compromising on the final design.”

With all project information managed with ENOVIA on the platform, VLP+P’s engineers can find the optimal solution to each new design challenge by referring to previous designs and analyses.

“The software gives us the freedom to obtain the geometry and develop a strategy to optimize surfaces according to the technologies and materials we’re using with that particular element,” Lucangeli said. “Glass reinforced concrete (GRC) panels have some constraints and glass does too, and our surface designs must respect these constraints. Every formulation from 3D geometry and coding of these materials is governed in the platform and we can reach all this information whenever we need it. We’re able to automate product templates, determine whether we use existing design components or create new ones. ENOVIA allows us to reuse our previous designs, share our knowledge with colleagues and define best practices, learning from what we did in a former job to help solve new, complex challenges. Having everything within a common data environment makes it easy for us to retrieve critical information.”

This capability is also invaluable for managing the lifecycle of a building as well as changes and revisions efficiently.

“Working on complex buildings means managing thousands of components and we need to track the lifecycle of every piece,” Lucangeli said. “The role to manage the engineering of building structures in the 3DEXPERIENCE platform is really useful for tracking revisions.”

Building with BIM for the future

Innovation has lead VLP+P to where it is today, and the company plans to continue adopting the latest design methodologies and industry best practices to achieve the best results.

“We’re currently developing the BIM for the French university ESPCI Paris,” Patron said. “We plan to use the platform to manage the BIM and use it to obtain a construction model with the highest level of detail. We’ve already developed a visual mockup for this building and designed a section of façade that delivers all construction requirement information, including shop drawings and bill of materials, to the client.”

Going forward, VLP+P hopes that it will inspire more of its clients to embrace BIM.

“We always aim to define with our clients the best methodology for interacting quickly and effectively, and the platform will certainly help us with this,” Lucangeli said. “We can now share our 3D models with clients in the cloud and we hope that they will increasingly choose this approach to interact with us, share information and find the best solutions.”

“We are constantly innovating the way we work,” Patron concluded. “When we started our business, we worked directly in 3D. Even now, it’s still not the industry standard. But we’re making progress and we’re encouraging more of our clients to move to the 3D era.”

Focus on VLP+P

VLP and Partners is a team of highly skilled engineers and architects, specialized in curtain wall 3D modeling, structural and thermal engineering of steel and façade cladding. The company’s expertise covers all phases of the building lifecycle, including assistance to architectural design, conceptual design, constructional design, production and installation. It helps clients predict the critical points of a project, analyze construction issues and identify patterns that optimize design and production. VLP+P’s programming knowledge makes it possible to achieve complex results in a short time, reducing the overall cost of the project.

For more information: www.vlpandpartners.com

Focus on IDeCOM

IDeCOM provides a portfolio of services combining its scientific and engineering capabilities. Its consultancy business vision is to be the partner of choice for high-value services to the civil infrastructures, energy and real estate sectors by delivering innovative solutions with a practical approach.