VIRAVER

Viraver in Italy develops and manufactures custom and complex glass structures for the yachting, automotive and architecture industry sectors. Implementing the 3DEXPERIENCE platform, Viraver’s engineers can define, simulate, analyze and validate an optimal design for each client with full traceability.

Reimagining glass structures

Visually striking and versatile yet structurally strong, glass has long been the material of choice for designers and architects as a means of opening up the interior of a super yacht, car or building to its outside environment. Modern advancements in the way glass is produced have led to ever-growing applications. It’s both a key design feature, infusing structures with fluidity and transparency in a way that no other material can, and a critical structural element capable of bearing large loads.

Founded in 2000, Viraver was set up to deliver innovative curved and high-strength glass for the next generation of yachts, cars and buildings being designed.. It is the company of choice for many leading shipyards, automotive manufacturers and architects, thanks to its industry-leading chemical strengthening processes and sag bending techniques to produce large glass sheets with complex curvatures. Since its foundation, it has built a strong global reputation around its ability to deliver large, thin glass applications to reduce weight, without compromising on resistance or structural and optical quality.

“Glass production has changed dramatically,” said Marco Mazzarolo, CEO of Viraver. “In the past, glass was fragile; today it is a structural, functional and styled element in a project. Our ability was to look ahead and understand what glass needed to do for each project and work closely with our clients to overcome their design challenges. We encourage our teams to find smart and reliable solutions. An example is the windshield developed for one of the most renowned shipyards in the world: a single six-meter sheet of glass with double curvature on the sides, which for the first time joins the central glass and the side windows of the wheelhouse. It’s a masterpiece.”

Viraver is driven by its vision - “Limits are where to begin, never where to stop,” - and its research and development efforts have led to the production of glass of ever-growing dimensions, applications and strength. In recent years, the company has invested heavily in its production facilities to support this goal, but recognized that it must also invest in its technological capabilities to maintain its position as industry leader and continue to fulfil clients’ expectations. The company needed an industry-leading technology platform to enable real-time and efficient information sharing during projects. It also needed to be capable of supporting and bringing together multiple disciplines to help them work together seamlessly. Viraver found the answer in the 3DEXPERIENCE® platform, including CATIA for design, DELMIA for bill of materials and production lifecycle management and ENOVIA for project management, which is now the backbone of its digital transformation.

“With the 3DEXPERIENCE platform we’re capable of gathering all the needs of a project and boosting and simplifying interaction between our departments,” Mazzarolo said. “Many of our customers, in yachting and automotive industries, already use the platform, and they’re very impressed we’ve invested in the same tool. It will allow us to share information, technical parts and drawings, in a matter of seconds, to resolve design issues and keep projects on track. We also hope the platform will help us strengthen our presence in competitive sectors, like that of the giga-yachts, automotive prototyping and special series as well as buildings, establishing ourselves as a leader in the development of technologically advanced products of the highest quality. We do not know today what we will create tomorrow, but we can create every day the conditions to imagine it.”

Viraver has constantly grown its business with targeted investments. We are committed to further speed up our transformation and the 3DEXPERIENCE platform is essential to our vision.

Driving a digital transformation

As Viraver embarked on its digital transformation, it needed a platform that is intuitive to use and could bring together all of its business processes to achieve digital continuity and empower everyone across the company to work together more effectively.

“To grow the business, we must have a vision, and Viraver is committed to being faster, more connected and efficient,” Mazzarolo said. “Through our digital transformation, we want to improve time to market, boost our production activities and empower our teams to work together seamlessly. We are confident the 3DEXPERIENCE platform will support to achieve our objectives.”

It was important for Viraver to choose technology that is industry-leading and would appeal to its employees.

“A digital transformation isn’t just about implementing technology; it’s a cultural change too, and we wanted our employees to embrace our new approach,” Mazzarolo said. “When we told our technicians that we had signed the contract to use the 3DEXPERIENCE platform, including the design application CATIA, they were all thrilled.

Viraver worked with Dassault Systèmes business partner Design Systems to lead the implementation and bring its digital vision to life.

“Design Systems is the leading partner, thanks to the flexibility they offer in the configuration and application of the 3DEXPERIENCE platform,” Mazzarolo said. “Their role is to manage the execution, configuration and analysis of the platform in collaboration with our key users.”

It was important for Viraver to choose both a technology and a partner it could rely on in the long term – capable of truly understanding and delivering a solution for its ongoing business needs.

“We strongly believe in team spirit, especially for this kind of project,” Mazzarolo said. “We are talking about a virtual system, but it is always people who define the needs, habits and developments. That’s the reason why Viraver believes in creating and building a strong human and professional relation – a real partnership, and that’s what we have with Design Systems and Dassault Systèmes.”

Virtual experience twin for better solutions

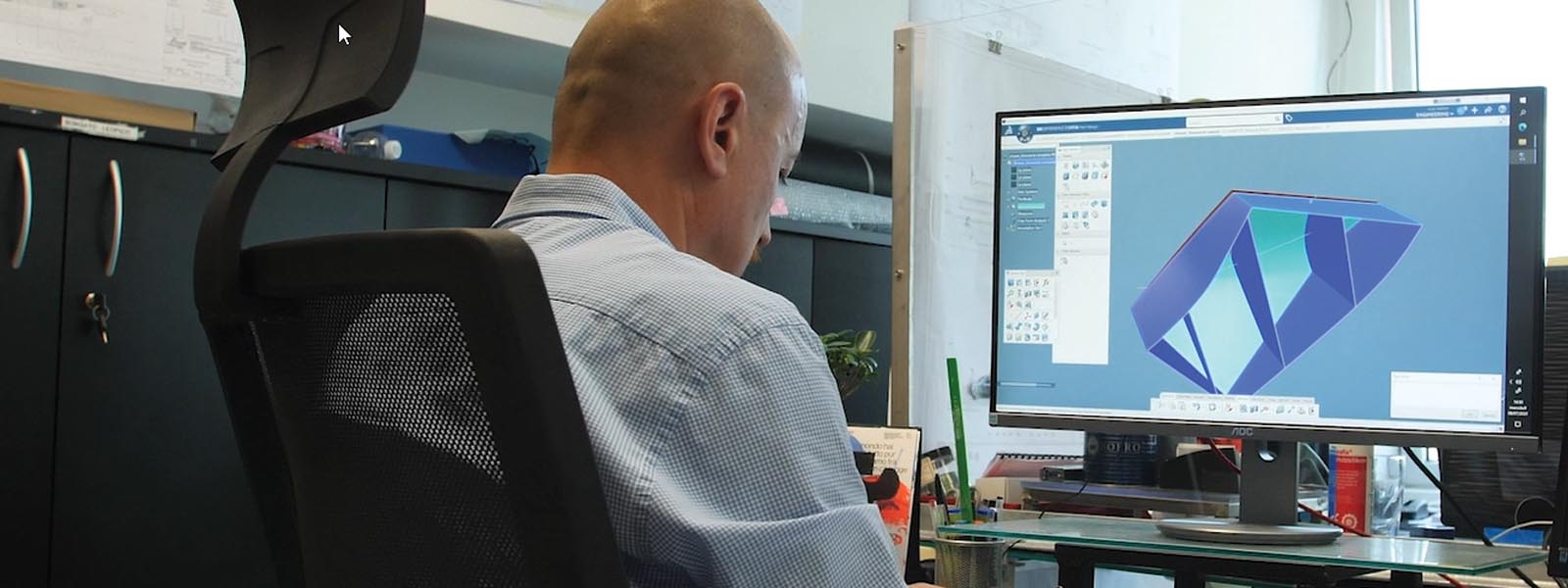

Viraver’s clients approach the company with increasingly complex and challenging design and structural demands as they seek to use glass at an ever-growing scale and in more applications. Each glass product is tailor-made, underpinned by hours of design innovation and research to create the best possible solution. Previously, this approach was very time intensive as engineers explored and tested multiple prototypes before finalizing each design. Now, using CATIA on the platform, they can design and simulate designs in 3D and create a virtual experience twin in DELMIA and ENOVIA, which they can share back and forth with the client before committing to building the physical product.

“Our aim is to optimize time and improve our production process to reduce the amount of trial and error in the prototyping stage, and waste,” Mazzarolo said. “We realized we were losing a lot of time looking for paper. We’re confident to be more efficient by digitalizing and streamlining our design processes as we can then spend more time on research, new product innovation and customer care. The 3DEXPERIENCE platform supports our design team to be more efficient, reliable and creative.”

Engineers use the advanced surface modelling functionality within CATIA to define the complex glass shapes. They can access all the data they need without having to switch between software, saving them time searching for information, and empowering them to design within context and in close collaboration with the client. Within DELMIA, they can define the production cycle early on, using the client-approved 3D design to produce the mold, plan the assembly process and produce work instructions. A process that used to involve many different software applications now takes place on one platform and is entirely digital.

“We used individual software to develop the drawings, another to produce the bill of materials and define the thickness of glass, the interlayers and tempering and so on,” Mazzarolo said. “In production, we had one laptop where employees could check information. But this wasn’t enough. They need to know all of the related information about each part as they work, such as the dimensions of the black band around the edge of the glass. This is particularly important in the nautical business as it protects the installation and guarantees the life of the glass. It’s where the glass is glued to the ship’s structure and it protects the adhesive bond. Now, they can verify these kind of specifications as they go.”

This new, more efficient design approach will also empower Viraver to deliver on its long-term sustainability goals. “Glass is a sustainable material and we are committed to being a truly sustainable company,” Mazzarolo said. “It’s part of everything we do, starting from our design concepts where we are always seeking to cut down on the materials we need to use, all the way through to production. We send 200 tons per year for recycling and use recycled glass in the form of new sheets in our factory for new projects. The 3DEXPERIENCE platform will support us to cut down on the number of gauges and control templates we need to make. We will also be able to reduce our raw material consumption by making fewer physical prototypes. Our yachting and automotive clients really like this push from us to become more sustainable.”

Clarity across disciplines

The 3DEXPERIENCE platform is being rolled out across multiple departments at Viraver, including its technical office, production, sales, procurement and project management teams. As each department is trained how to use and benefit from the platform’s capabilities for their day-to-day processes, they will be able to work more effectively on projects together.

“Our expectation is that the 3DEXPERIENCE platform will create synergies and guarantee modernity, leading to the instantaneous sharing of information, the readiness of answers and the creation of an interactive community,” Mazzarolo said.

Viraver expects the use of ENOVIA’s project management capabilities to improve efficiency across its business processes and lead to even higher quality products and better results for its clients.

“The pluses are to be found in an overall increase of quality and efficiencies of the information in the development process of the project, reduced production time, optimized consumption and quantity of materials used, and finally, high customer satisfaction,” Mazzarolo said.

Improved customer intimacy

One of Viraver’s greatest strengths is the relationship it develops with each of its clients to understand their design and structural requirements. It works together with them to overcome their unique challenges and deliver a tailored solution that delivers in terms of visual appeal and structural integrity.

“The relationship with our clients starts with the mutual knowledge of what we are able to do,” Mazzarolo said. “We shape and give functionality to glass and this is not something that is trivial. Our twenty years of experience allow us to support both the design and the engineering phases, and deliver bespoke products that challenge the laws of physics. This requires us to set production and quality standards that reflect customer expectations and comply with all classification companies and technical standardization committees.”

“We will be able to share information based on the same software as our clients,” Mazzarolo said. “We will share information and data through the platform. And with all the information at the project managers’ fingertips, we can achieve a ‘5G’ speed connection between us and our customers. The result is a seamless process, which reduces time and costs, and makes life simpler for the customer and relieves them of some heavy responsibilities. The 3DEXPERIENCE platform will be strategic for the ongoing interaction we have with our clients. Already, we are more efficient in meetings outside the company, because we always have with us, in real time, the overall project vision.”

Focus on Viraver

Viraver designs, develops and manufactures flat or curved sheet glass, laminated security glass and other bespoke glass products. Founded in 2000, the Italian company has grown to become a global leader specializing in glazing tailored to the yachting, automotive, architecture, industrial and armored sectors.

For more information: www.viraver.com

Focus on Design Systems

Design Systems is a leading CATIA, ENOVIA, DELMIA, and 3DEXPERIENCE platform reseller in Italy, recognized as a Dassault Systèmes Platinum Partner. Taking a consultative approach, Design Systems works with its clients to propose the most suitable and specific solutions for modeling, 3D simulation, and social and collaborative innovation.