Vesper

Germany-based Vesper is a specialist in designing and manufacturing high-quality specialist tooling for the automotive industry. The company adopted the 3DEXPERIENCE platform to further optimize processes and realize new efficiencies.

Challenge

Over the course of the last 35 years, Germany-based Vesper has earnt a reputation for developing, designing and manufacturing high-quality specialist tooling for the automotive industry. This includes complex machines that are used to create interior parts such as door panels, center arm rests, seat backrests and side panels. Its patented ‘non-slider edge-wrapping’ technology sets it apart from the competition, delivering space-saving construction methods and providing customers with enormous cost savings over conventional laminating and wrapping tools, as well as minimizing downtime and maintenance requirements.

Creating bespoke machines is no easy feat, especially when they are designed to be compact and involve complex processes such as edge wrapping. It’s a time- and resource-intensive process requiring a significant amount of advanced planning to ensure projects move quickly from development in CAD through to construction, which takes place in Vesper’s purpose-built factory.

To successfully compete in a market dominated by big players, Vesper realized it needed greater agility. Since every project it works on is different, it wanted to achieve a more streamlined development and execution process. What’s more, it wanted to better visualize the size and dimensions of the machines it would be working on so that employees on the shop floor could allocate space for construction.

Ultimately, Vesper’s leaders wanted the company to be able to react quickly to new customer demands, and to deliver high-quality, customized products much faster than the competition. They realized they needed to deploy a new collaboration platform that would enable it to optimize processes and realize new efficiencies.

Thanks to the 3DEXPERIENCE platform, all legacy design data is integrated directly. We now have instant access to up-to-date information, as well as optimized processes right across our organization. The centralized location of all data and processes is allowing us to future-proof our business and deliver the high level experience that our customers expect.

Solution

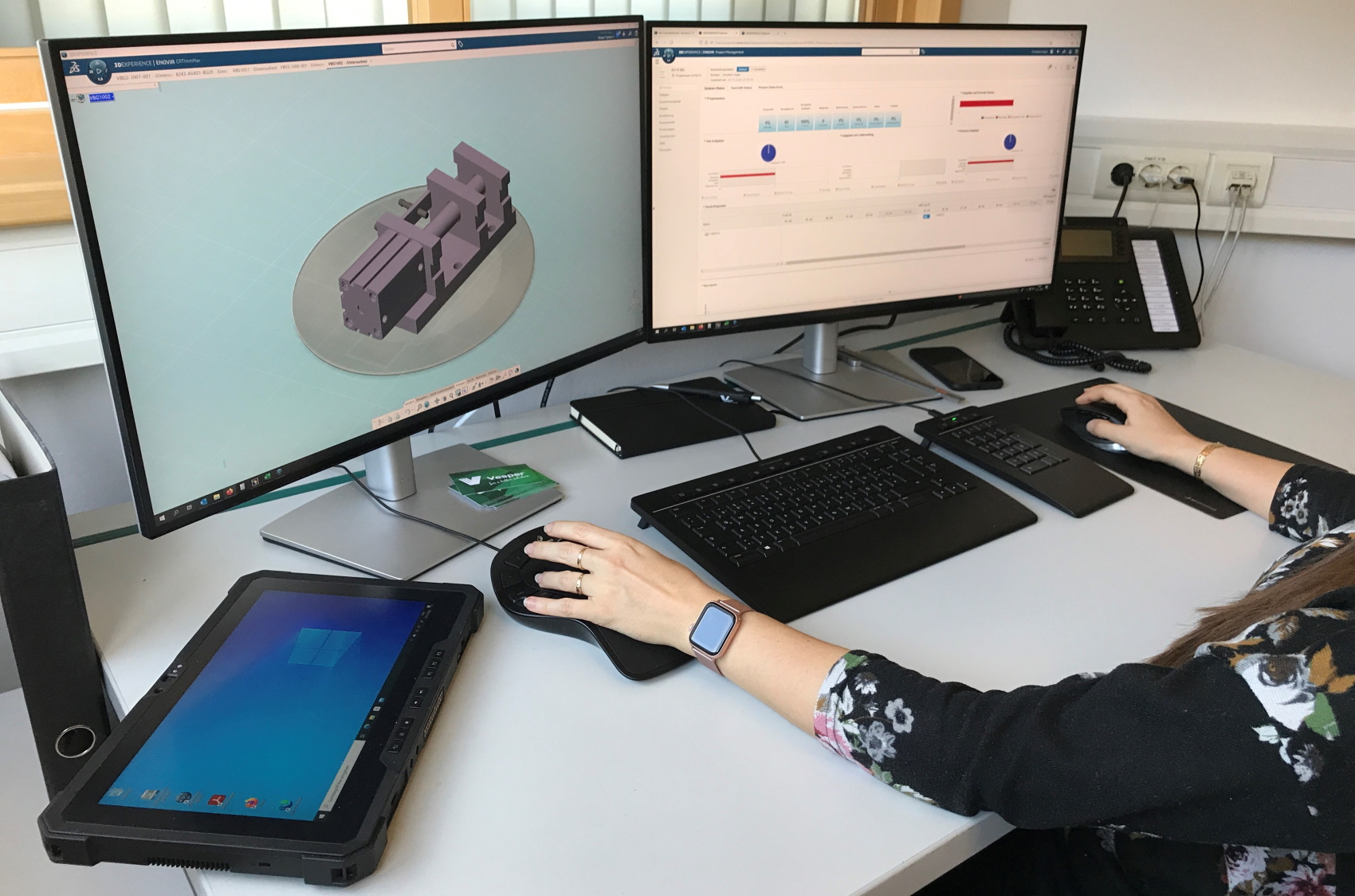

Vesper was already using Dassault Systèmes’ CATIA V5 solution, so the 3DEXPERIENCE platform was a natural choice, since it had the same familiar look and feel that employees were used to. The company is using POWER’BY to connect its CATIA V5 data to the 3DEXPERIENCE platform. ENOVIA provides the collaborative functionality and Vesper can reveal the design data for enterprise-wide sharing, easily search for components and access related documents – all from a centralized location.

Benefits

With the 3DEXPERIENCE platform, all Vesper employees benefit from instant access to up-to-date information and can immediately see the status of a project. This means they can allocate resources appropriately and ensure more productive use of time on the factory floor.

Efficiencies are being realized in multiple areas. With information silos eliminated, designers benefit from full version control. This means they always have access to the most up-to-date design files and, as a result, can prevent errors in production. Meanwhile, with an improved access to data engineers can reuse parts from existing designs. This cuts down design time, reduces the chances of creating duplicate parts and, as a result, helps reduce waste.

The ability to work collaboratively on designs has improved communication, reduced time spent communicating via different platforms, and resulted in more effective customer service. As a result, Vesper has been able to deliver on its commitment to deliver high quality customized products, and faster

This isn’t the end of the story. In the future, Vesper hopes to make greater use of the 3DEXPERIENCE platform by using ENOVIA for bill of materials management, and to streamline its processes further.

Discover more about the Digital Equipment Continuity industry solution experience.

Focus on Vesper

Established in Germany in 1982, Vesper supplies tooling and equipment for the automotive industry, including specialist machines for the production of various interior components such as door panels and backrests. All of its equipment is designed and manufactured in-house, and produced to the latest technical standards.

For more information: https://vesper-werkzeugbau.de/?lang=en

Focus on systemworkx

systemworkx is a long-term partner of Dassault Systemes, and prides itself on its ability to implement and support the full range of 3DEXPERIENCE solutions, according to individual customer needs. The company also offers a wide range of value-added services including training, consulting, workshops and implementation support.

For more information: https://systemworkx.de