Tezmaksan

Struggling to manage the large and complex assembly data for its robotic automation systems, Tezmaksan Robot Technologies relies on Dassault Systèmes’ solution for its powerful design and data management capabilities. The Digital Equipment Continuity industry solution experience provides a centralized environment through which the engineers can work concurrently in real time, reducing duplicate data and improving efficiency.

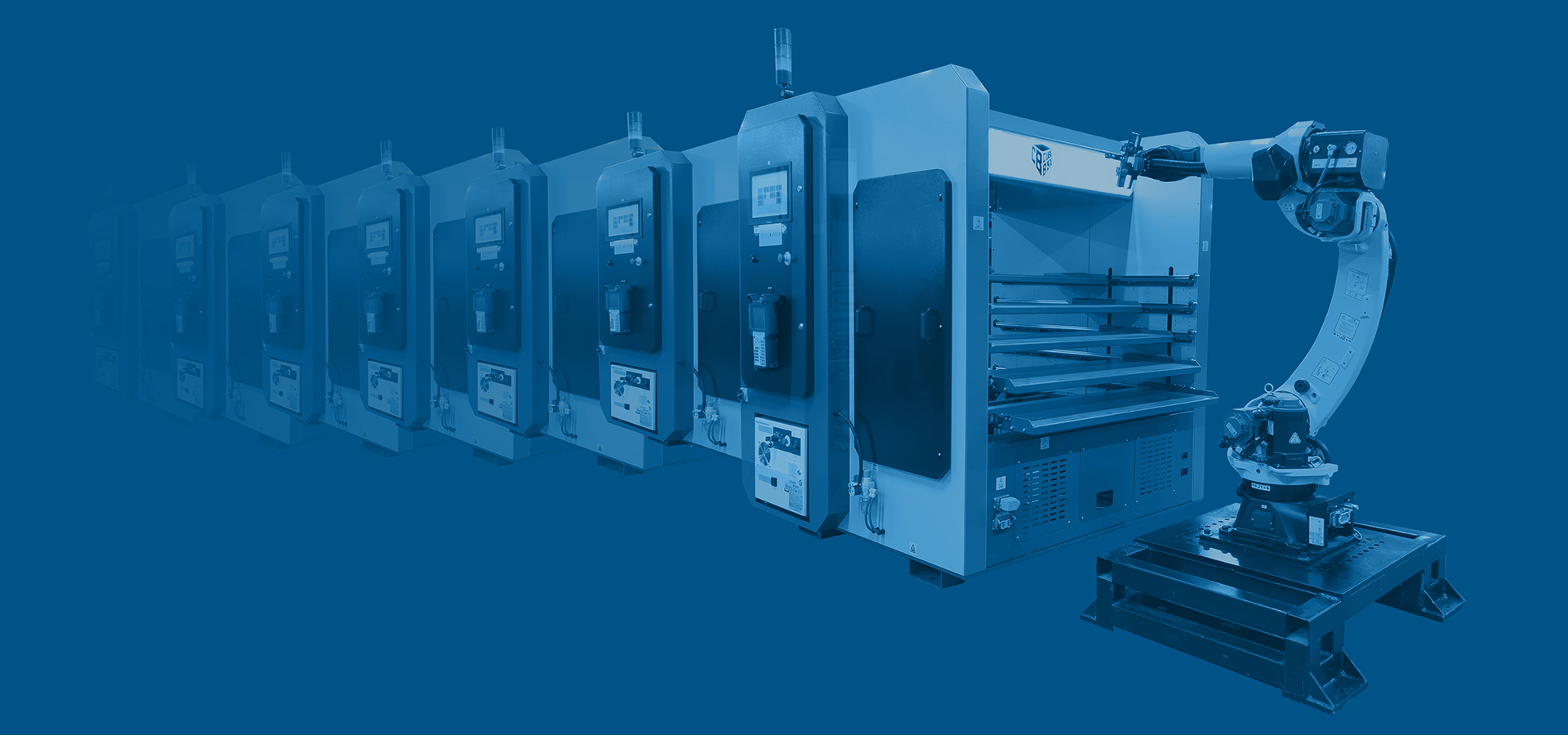

A revolution in robotic automation systems

Robotic automation systems are transforming factories worldwide, delivering precision and speed to intricate, repetitive tasks. The effective implementation of these technologies relies on machine operators and skilled software engineers who code, program and optimize robots for specific manufacturing needs. However, with recent Deloitte research revealing that almost two-thirds (65%) of manufacturers struggle to attract and retain talent, finding these experts is becoming increasingly difficult.

Recognizing this issue, Turkey-based company Tezmaksan Robot Technologies has created its CubeBOX systems – revolutionary robotic automation solutions that can operate around the clock without an operator. This continuous operation maximizes production output, enhances productivity and reduces lead times. In fact, according to Tezmaksan, users can boost night shift efficiency by 50% compared to manual machine tending.

ROBOCAM, Tezmaksan’s intelligent automation software, is the foundation of its CubeBOX systems. It enables manufacturers to integrate CubeBOX with any compatible robot, eliminating prior robot programming expertise. Users simply upload product drawings and ROBOCAM translates them into a robot-friendly language, enabling seamless communication and task execution.

The company has inaugurated its state-of-the-art factory in central Turkey. This, along with the productivity gains it is realizing by adopting Dassault Systèmes’ 3DEXPERIENCE platform, will help it ramp up the production of CubeBOX in the coming years, and reach its goal of achieving a €100 million turnover by 2030.

Thanks to the 3DEXPERIENCE platform, we have increased our productivity in design, production and automation processes. By enhancing communication between our departments, we have minimized errors and started to accomplish more in less time. As a result, the price of CubeBOX products has been reduced, making it even more competitive on the market.

Challenge

Tezmaksan’s CubeBOX systems are complex and contain a large amount of assembly data. The company’s engineers found that managing this data in their existing environment was becoming increasingly challenging. Loading and saving the various part files was sluggish, costing the company valuable time.

The company’s file management system was also hampering productivity. Engineers, situated in various spots and all working in different ways, were saving design files in a multitude of places. There was no consistent way of numbering parts. This led to a huge number of duplicate designs spread across many locations – and this caused errors, as it was impossible to know which design was the most up to date.

Tezmaksan realized it needed a powerful design solution capable of handling complex data as well as a better document management system. It turned to local Dassault Systèmes business partner Yenaplus for advice.

Solution

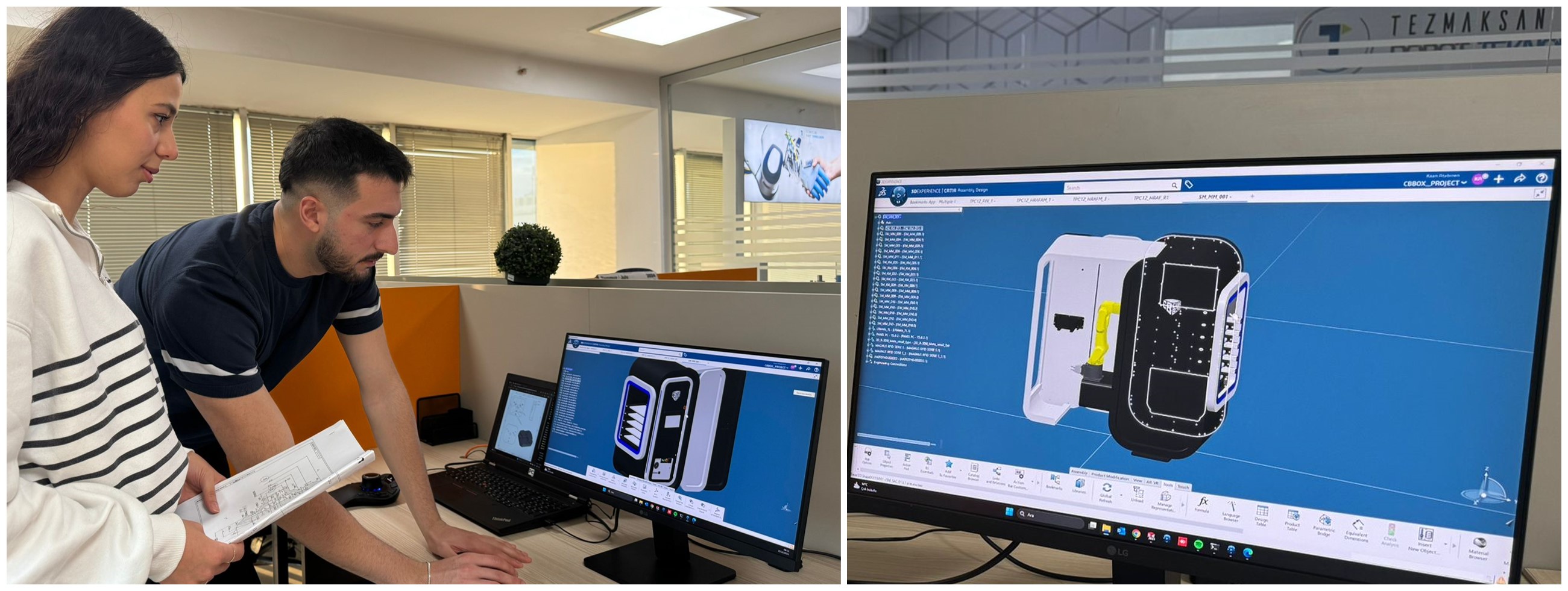

Yenaplus met with the Tezmaksan team and analyzed its existing architecture, key requirements and expectations before presenting the 3DEXPERIENCE platform capabilities. Once the team saw the potential of CATIA for design, along with the product data management capabilities of ENOVIA, it realized it could benefit from leveraging the 3DEXPERIENCE platform.

The partner set to work configuring Tezmaksan’s on-premise services and testing them on the company's servers. The installation of CATIA was straightforward and took around a week. Following a brief training period – and with Yenaplus on hand to provide technical support – Tezmaksan’s engineers were able use the application effectively.

Yenaplus then began customizing and implementing ENOVIA. Overall, the full deployment was completed in around seven months.

Benefits

Now collaborating on the 3DEXPERIENCE platform, Tezmaksan’s engineers benefit from a unified user experience for all processes.

Design data is organized in a logical and orderly fashion. No matter where engineers are located, ENOVIA’s product lifecycle management capabilities mean they can work concurrently in real time from a single source of information. Duplicate parts are now a thing of the past and, as a result, errors are reduced.

Tezmaksan’s engineers enjoy CATIA’s user interface. With every application within the design application benefiting from the same logic and workflow, users have found it easy to learn how to use specialized functions.

Productivity and efficiency have increased thanks to time-saving benefits. Because CATIA has been designed to work with large assemblies, there are no delays in opening or saving parts. Moreover, by adding frequently used commands to an action pad, users can navigate between applications without changing the interface.

Further time is saved thanks to CATIA’s parametric features, which allow engineers to make changes to a specific part’s dimension or constraint, and then apply those changes to new designs, thus benefiting from the same part in a single click. Existing parts can be used in new products by simply dragging and dropping them into a design.

Buoyed by the benefits it has realized so far, Tezmaksan is keen to leverage more of the 3DEXPERIENCE platform in the future. It has recently begun exploring how the Structural Designer role might help it simulate the performance of its automation solutions, and easily and efficiently test product designs. It is also looking to adopt the Piping and HVAC Engineering and Electrical Wire Harness Engineering roles so that it can more effectively analyze and validate its products’ systems and create intelligent schematics for a complete detailed system definition.

Additionally, it hopes to leverage ENOVIA’s sophisticated project management capabilities so that all stages of its projects are carefully planned and monitored, ensuring customer needs are always met on time and within budget.

Discover more about the Digital Equipment Continuity industry solution experience.

Focus on Tezmaksan

Founded in 1981, Tezmaksan Robot Technologies is at the forefront of innovation in the CNC automation industry. With a global presence and worldwide dealer network, the company aims to empower manufacturing businesses with automation solutions that enhance efficiency, productivity, and overall performance. For more information: https://tezmaksanrobotics.com

Focus on Yenaplus

With over 25 years of experience in the software industry, Yenaplus is a Dassault Systèmes channel partner with a focus on delivering exceptional customer service. By integrating the full capabilities of the 3DEXPERIENCE platform, including the ENOVIA, CATIA, SIMULIA and DELMIA solutions, Yenaplus ensures that its clients remain one step ahead of their digital transformation journey. Thanks to its purpose-built Yenaplus software called Yenatools, the partner can complete the tedious work that used to take days in seconds, saving its customers both time and money.