Ten Tech

3DEXPERIENCE solutions on the cloud-enabled the TEN TECH team to access the full portfolio of SIMULIA simulation tools, collaborate effectively, and achieve results efficiently.

The days of the analog pay phone are almost over. Even if you can find one, it’s likely in poor condition, especially if located outdoors. The cell phone is now king of digital communications and major cities around the world are beginning to accommodate that reality with next-generation technology. The condition of the remaining battered and bruised pay phones is a reminder that any new public communications devices need to be able to stand up to a lot of hard use—and even abuse.

New York City’s hustle and bustle certainly creates a tough environment for innovative on-the-street phone technology. But that hasn’t slowed down the City’s zeal for replacing every pay phone with something completely different: the LinkNYC system of outdoor tech kiosks that provide free public wi-fi on a secure, private network, access to broadband, device charging, toll-free phone calls to anywhere in the U.S., a tablet for maps and city services, environmental monitoring and more. Plus big-screen advertising, which defers the City’s (and taxpayers) costs for the units.

Already numbering upwards of 1700, with 5 million users in just two years, the ultra-modern Link obelisks are popping up all over Manhattan and its neighboring boroughs (final goal: 7,500 units). Similar projects are now underway in other major U.S. and European cities as well.

A Military Background Creates a Mindset of Quality

The challenge of proving out the functionality and durability of the LinkNYC was a custom fit for TEN TECH LLC. Their experience delivering robust, top-quality design engineering solutions for military applications helped them win a support contract with Comark, part of the CityBridge Consortium in charge of designing and manufacturing the LinkNYC kiosks. Says TEN TECH LLC founder and VP of Engineering Will Villers, “’Failure is not an option’ may be a cliché, but it’s certainly true for us. A product recall on the battlefield is a lot more dramatic than the manufacturing recall of a cell phone. We build extreme reliability into everything we design or help design.”

Villers founded the company after leaving another firm where “their business model was more focused on quantity than quality, which is not what I wanted to do.” That strong emphasis on quality has kept TEN TECH LLC on an upward growth path into its eighth year now.

Designing for the Urban Battlefield

So how do you design a LinkNYC kiosk to withstand the rigors of the urban battlefield of both natural and human extremes? “Every city has its unique requirements,” says Villers. “In California it might be earthquakes, in Florida it might be hurricanes, but in cities like Boston or New York it’s temperature swings from 110 degrees in summer to well below freezing in winter. There are also common physical events (for which the City provided loads requirements) like being backed into by a car, hit by a bus, or—and we actually tested for this—struck with a baseball bat (by someone trying to break in assuming there’s cash inside, which is not the case).”

Before it takes on the rigors of city life, each LinkNYC needs to stay put where it’s installed. “For us this began as essentially a civil engineering project,” says Villers. “First we had to figure out what would be the ideal skeleton inside the box and how deep its steel beams needed to be anchored in cement. It was a lot like designing a small building."

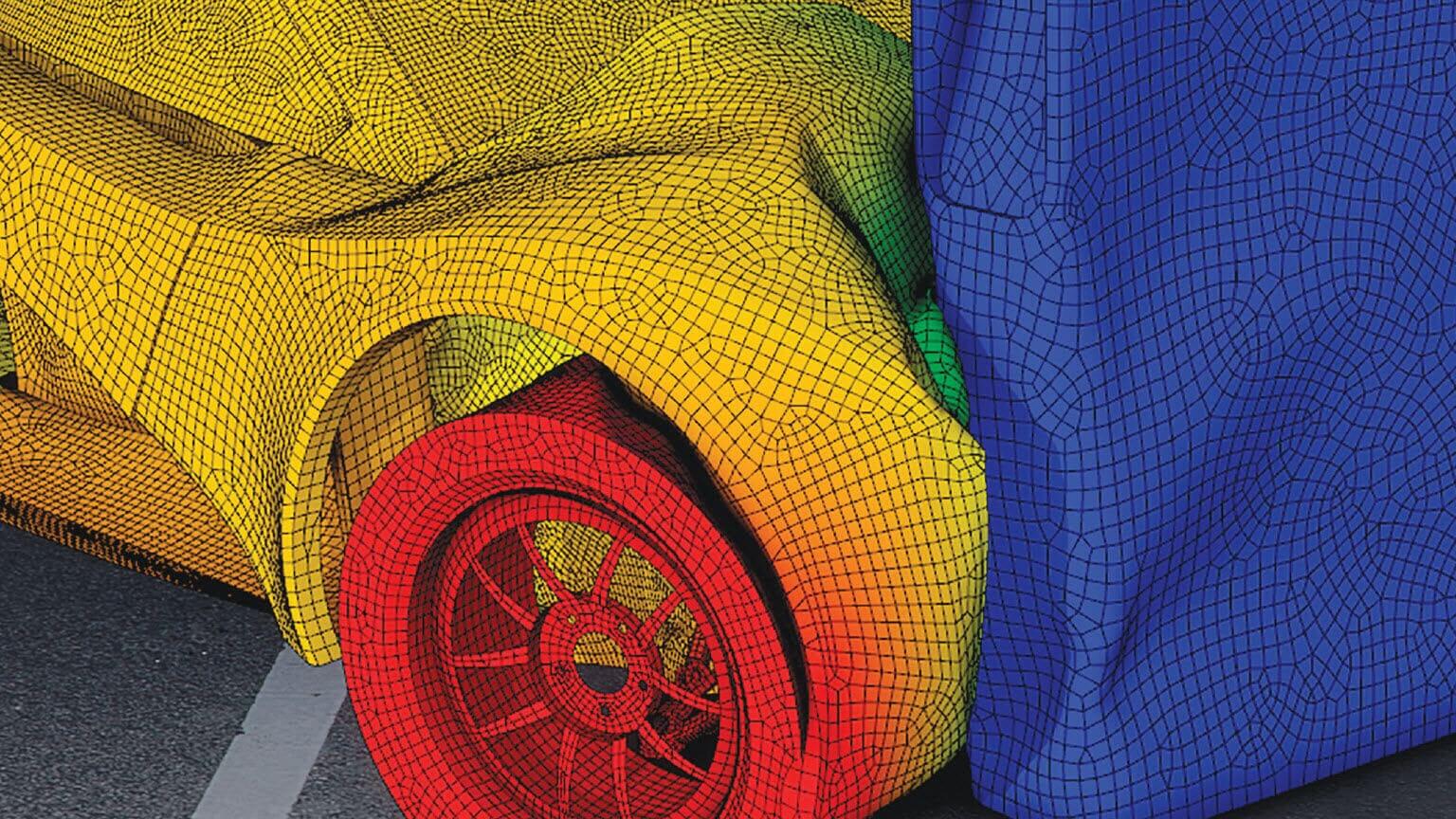

Once properly anchored, the “small building” also has to act something like a side-of-the-road traffic barrier, able to repel a certain amount of vehicular impact without being crushed. “The exterior material was aluminum for durability,” says Villers. “To survive these types of loads you want to offer the right balance between flexibility and strength: flexible where possible to dissipate energy and strong where you can’t allow deformation. Simulation is a great tool for finding that sweet spot in the design. We used Abaqus here for structural mechanics to assess stress, deflection, buckling and so forth.”

The exterior, obelisk-like shape of each kiosk was created by the renowned industrial designer Masamichi Udagawa. It is both compact and sweeping, with simple, clean lines and easy access for users at ground level, but significant height (9.5 feet) for visibility on a crowded sidewalk. “Creating an aesthetically pleasing exterior is one thing,” says Villers. “But making sure if can also withstand the environment, including snow load in the winter, is another challenge.”

Creating an aesthetically pleasing exterior is one thing. But making sure if can also withstand the environment, including snow load in the winter, is another challenge.

Demonstrating Expertise with 3DEXPERIENCE

The value of aesthetics extended beyond looks when TEN TECH LLC had to periodically present results to the LinkNYC project managers and stakeholders. “The ‘coolness’ factor of showing the project via the 3DEXPERIENCE® onscreen was definitely something that caught their attention,” says Villers. “Simply being able to visibly demonstrate our advanced capabilities, instead of presenting an overly complicated engineering equations and diagrams, made them realize how advanced our methods were.”

The Platform also facilitated creating all the documentation that TEN TECH LLC’s client needed to demonstrate qualification and facilitate certification, which was critical for final approval from the State of New York’s Professional Engineer (PE).

Rain, Snow, Sun - and Electronics

Inside the LinkNYC there were a myriad of design challenges to overcome: a variety of electronics needed to be protected from the elements, fit together optimally, and function properly without overheating. “Ensuring the survival of everything inside—all those wires and pins and electronics that nobody sees, plus 55-inch LCD screens that generated a lot of heat, as well as environmental load from the sun and rain—this created all sorts of interesting requirements,” says Villers.

Moisture protection and water ingress were also very important, he notes. “We did a lot of work on rubber gaskets, because all these electronics were running outdoors and we had to make sure everything was watertight.” Each unit’s ingress protection is put through its paces in indoor test showers mimicking heavy rain.

But interior heat was the most widespread concern. With the main power source provided by the City’s underground cables, “special attention needed to be paid to an internal cooling strategy; some components would shut down if they became too hot, others could potentially even catch fire,” says Villers. “We used design strategies based on things we see in the defense industry that consumer product designers aren’t necessarily aware of.”

While the solution involved a large number of fans, it also hinged on appropriate placement of all the electronics so they didn’t interfere with each other, plus strategically located vents to let hot air out without it hitting any users or passers-by. Decisions about interior layout were part of the overall design loop, since cooling requirements also impacted the geometry of the exterior.

Putting the Portfolio to Work on the Cloud

The capabilities needed to manage all this design complexity came through TEN TECH LLC’s license for the 3DEXPERIENCE Platform on the cloud. “I have only good things to say about the cloud for this kind of project,” says Villers. “We could access the full SIMULIA portfolio of simulation tools from wherever we were, whenever we wanted. Our team could work together at all hours of the night, even from a hotel room with lousy wi-fi when we were travelling, and still be able to retrieve assemblies, do reviews, all without any problems.”

Design changes were easy when working on the Platform on the cloud, Villers says. “We had access to the full suite of SIMULIA tools for structural, linear and nonlinear statics, CFD, fatigue and durability, even some shape optimization for brackets (which we could have done by hand but it was fun to see what the computer would come up with). We did some optimization as well. Because everything was integrated, the tools all worked very well together.

“So when you changed something in CATIA, it would be reflected in SIMULIA, and everyone on your team would be instantly updated and could coordinate their work. As the main design was an assembly in SolidWorks it was so easy just to shift to the 3DEXPERIENCE for analysis. We found a lot of benefits in working together this way on the cloud.”

Virtual Installation Provides a Realistic Look

Live rendering of near-final designs helped communicate with all the different audiences involved in the project, the engineers found. “The graphics quality of 3DEXPERIENCE is noticeably better than a lot of CAD applications,” says Villers. “We were able to demonstrate how the kiosks would look in place, with the city in the background. When you can show something that way to people who are not necessarily technical they are very impressed. Engineering can seem boring to some, but if you can make it cool at the same time, people pay more attention!”

Confidence in the final designs was high and prototyping was minimal. “Our clients can now go straight from CAD directly to fabricating,” says Villers. The kiosks are being manufactured in Massachusetts and trucked down to New York City. Every installed LinkNYC kiosk is standing up well to whatever the City’s lively environment comes up with. Says Villers with noticeable pride, “We’ve had no complaints from our client. As far as we’re concerned it was designed right the first time using 3DEXPERIENCE Platform on Cloud.”