Ruroc

To meet the exacting demands of extreme sports enthusiasts, UK helmet brand Ruroc needs to innovate quickly. Acting as a central repository for all design data regardless of format, the 3DEXPERIENCE platform, along with the Perfect Consumer Product industry solution experience, provides a powerful multi-CAD environment that allows Ruroc’s teams to collaborate more efficiently and bring its products to market faster.

(Photo © Ruroc)

Developing high-performance helmets for thrill seekers

Extreme sports enthusiast Rob Gavin incurred severe face injuries in a 2008 snowboarding accident, when an avalanche left him buried in snow. Realizing his wounds could have been prevented if he was wearing a more protective helmet, but unable to find anything suitable on the market, Gavin set about designing his own. This led to him founding Ruroc – a UK-based company with a following of over four million extreme sports enthusiasts.

Ruroc’s debut product, the RG1-DX, was the world’s first full-face ski and snowboarding helmet. Designed using Dassault Systèmes’ SOLIDWORKS software, it boasts unique features such as a patented airflow system and integrated anti-fogging goggles and remains a bestseller to this day.

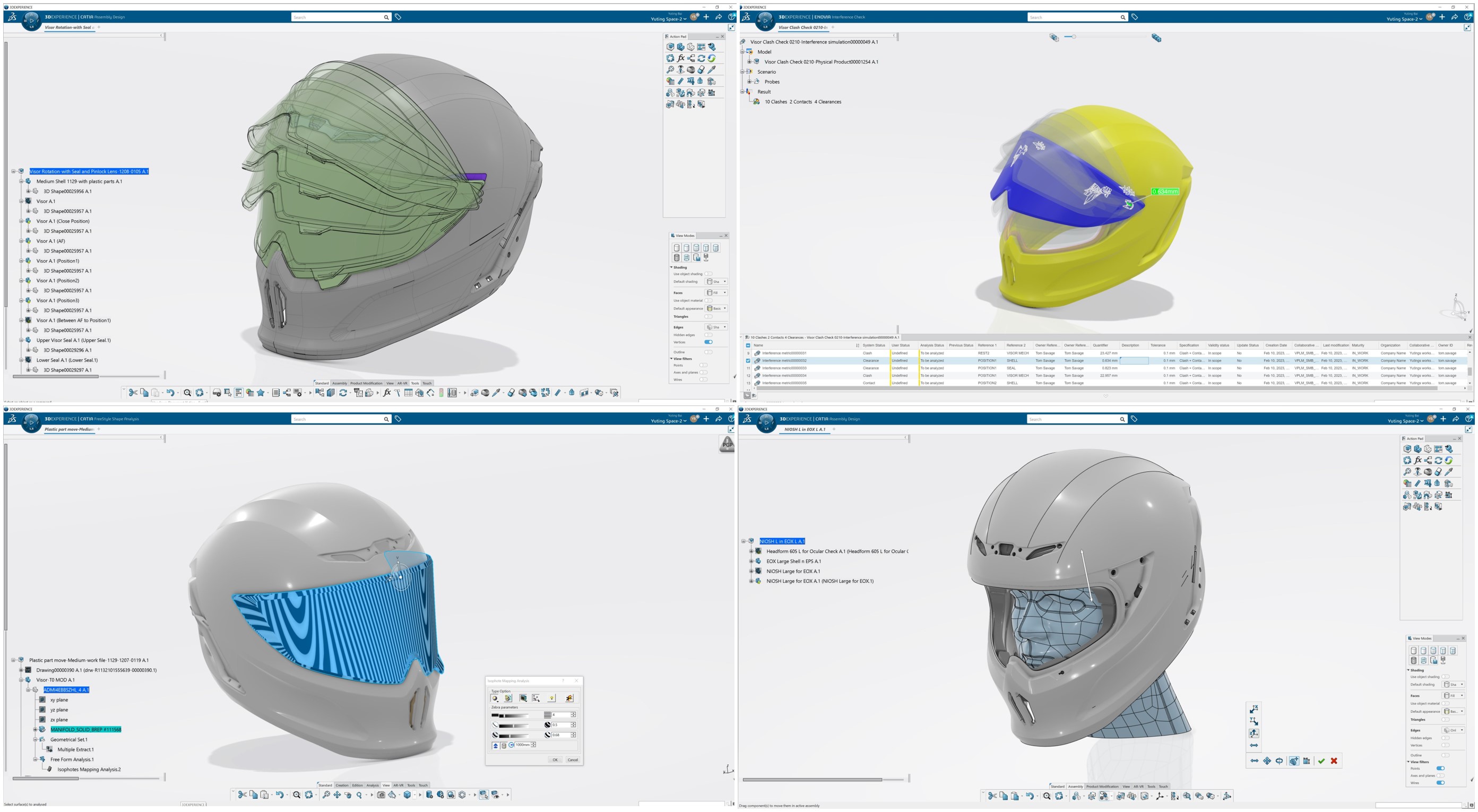

Selling directly to end users, rather than through retailers, Ruroc prides itself on reacting to direct customer feedback. To develop ideas and iterate designs faster than the competition, Ruroc sought a single integrated design solution that would make collaboration easy. The 3DEXPERIENCE® platform on the cloud stood out, offering a multi-CAD environment that would allow designers to import various CAD formats.

“Everyone at Ruroc has different skillsets,” said Tom Savage, Ruroc’s head of design and engineering. “Some people are brought up on CATIA V5 and others prefer to use SOLIDWORKS. Meanwhile, our design for manufacturing sub-contractor Generative Parametrics was using Dassault Systèmes’ 3DEXPERIENCE platform on the cloud with CATIA as the design application."

Ruroc found that adopting the 3DEXPERIENCE platform itself could enable its designers to utilize the application they are most comfortable with.

“Everyone can lean into their own skills,” Savage said. “Learning the platform was straightforward. Each member of the team had personalized onboarding. We also had help from the Dassault Systèmes User Communities, a forum where we can post questions and get answers back incredibly quickly.”

Whether it’s motorcycling, skiing or snowboarding, we aim to be the go-to head protection brand. And we see Dassault Systèmes as a partner to help us reach this goal.

Meeting high regulation and consumer expectations

To remain ahead of its competitors, the company needs to act on its users’ feedback quickly, while meeting stringent regulations. There have been a lot of changes and modifications to industry standards.

“The latest Economic Commission for Europe (ECE) 22.06 safety standard, for example, pinpoints rotational energy absorption,” Savage said. “It also requires high levels of penetration resistance and positional stability. This means our helmets must be tested under various angles of impact at a range of different speeds.”

For Ruroc to succeed, it needs close collaboration between its multidisciplinary teams as well as with Generative Parametrics. However, until recently these parties were working independently using a file-based system. With designs stored locally and in different formats, collaboration was proving difficult. Moving towards a data- and process-driven environment based on the 3DEXPERIENCE platform has turned things around.

“Because the 3DEXPERIENCE platform is cloud based, we now have good cross-collaboration between teams,” Savage said. “We can work together with Generative Parametrics seamlessly in real time and from the same file structure.”

A streamlined approach to helmet design

With 3DEXPERIENCE as a solid foundation, Ruroc continuously innovates. As soon as a brief has been formulated, initial sketches are made and customer feedback is incorporated. Using the 3DEXPERIENCE platform’s bookmark function, Ruroc teams were able to organize critical 3D data by project, ensuring that design information from various sources is stored in a logical way. Ruroc’s design process is now much more streamlined.

“My goal is to listen to customers' feedback and develop something in a conceptual space,” said Jason Esson, Ruroc’s senior industrial designer. “And then, when that data does go over to the other design engineers, they will use the platform to take the designs through to manufacturing without having to backtrack too much.”

Esson’s sketches are imported into SOLIDWORKS or CATIA so that complex surfaces can be developed. Once the surfaces are created, the helmet’s design is further refined. Using CATIA’s Part Design and Generative Shape Design apps, for example, designers can engineer precise 3D mechanical parts and assess the comfort and thermal properties of the helmets.

“By comparing some of the 3D data, we’ll know for example whether the location of headphones inside the helmet would be comfortable for the user,” said Yuting Bai, Ruroc’s design engineer.

By generating a products library of existing parts on the 3DEXPERIENCE platform – including the Bluetooth communication system, spoiler, nose vent and visor – Ruroc can simply drag and drop components into new designs, rather than starting from scratch.

“Even the visor is used across all three shells,” Esson said. “We found it quite helpful to only have to build those components a single time.”

Once finalized, the design can be easily scaled to create various helmet sizes.

“The good thing with the 3DEXPERIENCE platform is that, when we’ve built one size of helmet, we can use the parameter function to scale the design up and down to create other helmet sizes,” Bai said. “That saves us a lot of time.”

The path to virtual prototyping

Ruroc is now focused on building its material library inside the 3DEXPERIENCE platform, which will allow it to calculate the weights of the components within the different helmets’ shells. In the future, this data, along with the platform’s computational fluid dynamics capabilities, would help Ruroc calculate drag and flow, as well as thermal and acoustics properties. By virtually simulating product performance, Ruroc could reduce its reliance on physical prototyping.

“It currently takes a long time to get prototypes from the factory,” Bai said. “With physical prototyping, we can only test a helmet once – after that it is ruined. It's just like with car crash testing. It will be interesting to see how simulation compares to the real live results.”

“It will be great to see the initial first analysis of what we can expect from the performance of our 3D parts when we go into the wind tunnel and start collecting real world data,” Savage added. “Virtual testing through the 3DEXPERIENCE platform would help us to correlate that data and make more informed decisions rather than waiting for the first prototypes.”

This will enable Ruroc save time and money, and also diversify its product portfolio quicker to meet demand from new markets. Its latest motorcycle helmet range – the EOX – has been completely developed on the 3DEXPERIENCE platform and with the help of over 150,000 riders and is described by the company as ‘defining a new dawn for Ruroc’.

It’s an exciting time for Ruroc, and – thanks to the 3DEXPERIENCE platform – the company is on the way to realizing its vision: to become the go-to brand for head protection, for every extreme sport.

Focus on Ruroc

Founded in 2007, Ruroc offers unique products designed to take rider experience and safety to the next level. What began as a team of three people passionate about revolutionizing the world of snow-sports protection in Gloucester, has become one of the fastest-growing brands in the UK. The Ruroc headquarters are still based in Gloucester, along with its expert engineering team responsible for design, development and testing, as well as marketing, customer experience and quality control teams. The company now ships to over 100 different countries and employs over 160 members of staff.

For more information: https://www.ruroc.com