From Classroom to Racetrack Success: Inside the Polimi Motorcycle Factory Racing Team

Polimi Motorcycle Factory leverages the design and simulation capabilities of the cloud-based 3DEXPERIENCE® platform to increase collaboration and save time.

Challenge

The Polimi Motorcycle Factory, a racing team made up of students at the Polytechnic University of Milan (Politecnico di Milano) needed a tool to design and develop a motorbike to compete in the MotoStudent International Competition where motorcycles undergo rigorous static and dynamic trials before racing at MotorLand Aragón in northeastern Spain.

Solution

The PMF team began a sponsorship with Dassault Systèmes to leverage CATIA for CAD and SIMULIA simulation technologies, including Abaqus, PowerFLOW, Isight, fe‑safe, Fluid Dynamics Engineer, and Simpack for advanced design optimization, leveraging the cloud-based 3DEXPERIENCE® platform for streamlined collaboration and data management.

Result

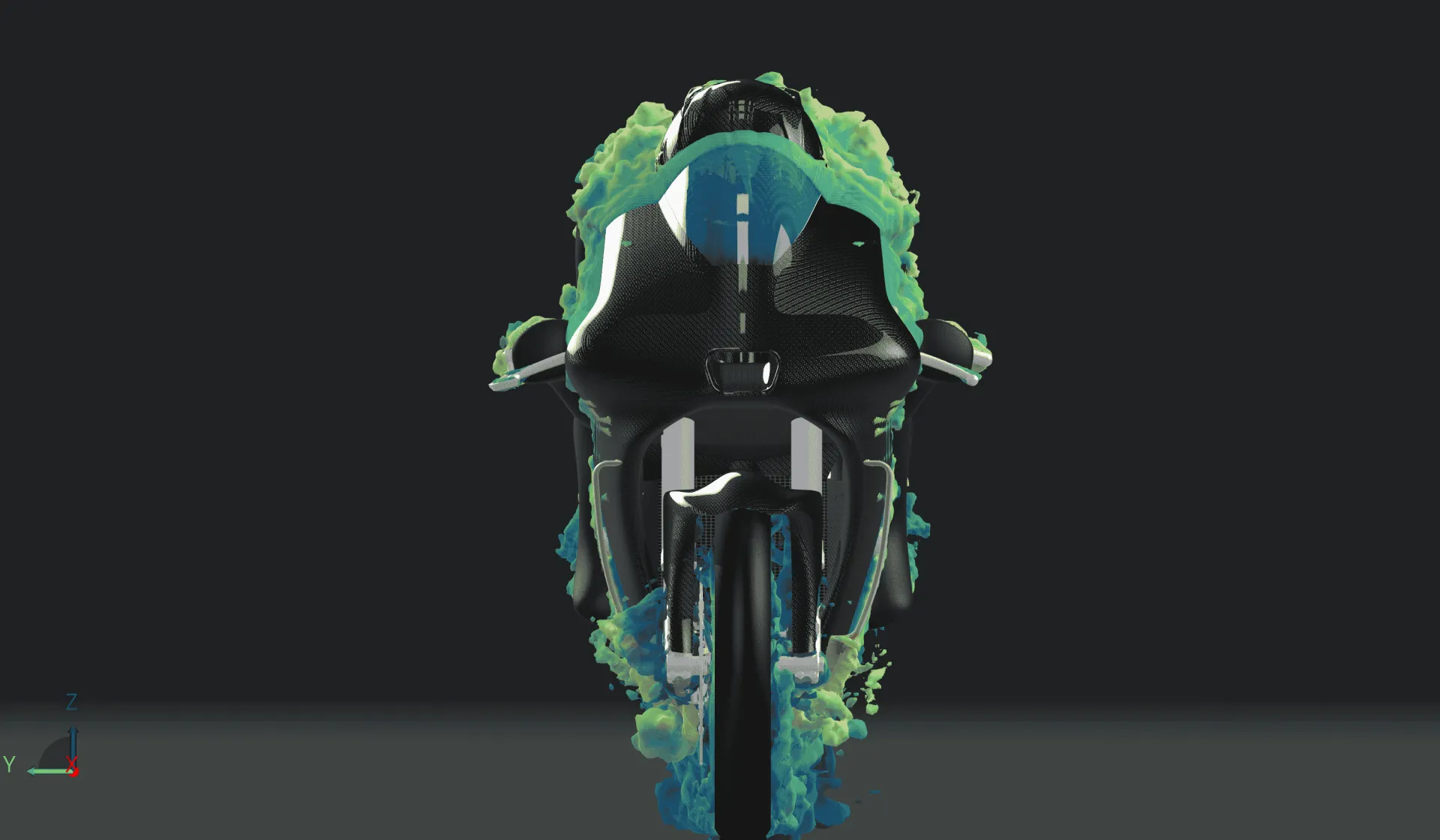

The Polimi Motorcycle Factory team has seen great success over the years, winning several MotoStudent competitions. Developing an aerodynamic airbrake device that disrupts airflow during braking is one of PMF’s most significant achievements. The airbrake efficiency on straights has been enhanced by the presence of C-wings: PowerFLOW enabled PMF team to simulate the entire prototype down to the smallest details. Another significant game-changer is a nearly 50% weight reduction of the rear swingarm compared with its predecessor, using of Abaqus for topology and sizing optimizations.

Polimi Motorcycle Factory (PMF) team members are students in the Department of Mechanics at the Polytechnic University of Milan (Politecnico di Milano). The team was formed to participate in the MotoStudent International Competition, where universities worldwide compete in designing, developing, and manufacturing combustion engines and electric racing motorcycles. The competition culminates in a MotoStudent event at MotorLand Aragón in northeastern Spain, where motorcycles undergo rigorous static and dynamic trials before racing.

The PMF team was established in 2015 by five mechanical engineering students driven by a passion for motorcycles. Developing a motorcycle for the MotoStudent event from idea to competition requires an interdisciplinary team of students from mechanical engineering, energy technology, aerospace, electrical and civil engineering, as well as disciplines such as management, design and architecture.

The MotoStudent event draws top-shelf competitors from university teams around the world for good reason: Students get to drive innovation into a product they build with their own hands. Theoretical learning becomes reality as research and development, design, testing, engineering, and almost every aspect of bringing a product to market, along with the inherent pressures, must be managed. Each and every team experiences the challenges of communication and collaboration: Along with celebrated successes, mistakes become valuable lessons learned that students take into the real world.

The MotoStudent organization provides the same two types of engines to every team in the competition. The petrol (gasoline combustion) engine outputs about 35 kilowatts of peak power, whereas the electric motor outputs about 48 kilowatts. Other than the motor and braking system, all prototype parts must be either bought or produced by the student teams. This hands-on project requires that students apply their academic knowledge in a realistic industry setting, including facing deadline pressures and direct competition.

Revving Up Motorcycle Production

In their debut, the PMF team achieved significant success by quickly creating a compliant motorcycle prototype that finished well in their first competition. By 2018, the team expanded to more than 80 members and won the world champion title in the Petrol category with their Sciura prototype. In 2019, the team of more than 100 members began a sponsorship with Dassault Systèmes to leverage CATIA for CAD and SIMULIA simulation technologies, including Abaqus, PowerFLOW, Isight, fe‑safe, Fluid Dynamics Engineer, and Simpack for advanced design optimization, leveraging the cloud-based 3DEXPERIENCE® platform for streamlined collaboration and data management.

In 2021, the PMF team showcased its versatility and growing dedication to the MotoStudent Competition by entering two prototypes: one petrol and one electric – demonstrating its commitment to embracing sustainable technology. The team placed first in the Best Industrial Project competition that year. Then, in 2023, PMF became world vice-champions (second-place winners) in the Electric category race with its Tatanka prototype. Building two different motorcycles was not an easy task as the team designed and manufactured twice as many parts.

"The electric prototype chassis was one of the most challenging components to design since it differs from the petrol's in many aspects, such as the need for mounting support for the primary transmission and the battery pack. Fitting all those components together was not easy," emphasized Luca Ambrosini, head of Finite Element Analysis and mechanical engineering student on the PMF team.

The PMF team must learn to use industry-standard engineering tools to build every component during this process. The Fairings and Aerodynamic department relied heavily on advanced surface modeling tools available on the 3DEXPERIENCE platform, using xShape and CATIA's ICEM to design components such as fairings and mudguards. The team relied significantly on Abaqus' Finite Element Method (FEM) simulations to validate the integrity and performance expectations of their designs, including detailed analyses like frequency and fatigue assessments on key structural elements.

Full Throttle Product Development

The most monumental challenge for the PMF team is coordinating numerous working groups that handle training, research, development, design, and production, all condensed in a tight two-year timeframe.

"We use the 3DEXPERIENCE platform for CAD and PLM, managing the whole prototype lifecycle with the huge range of apps provided. For example, we use Member Control Center and Project Planning to get a top-down view of the development process of the prototypes," explained Roberto Trani, aerodynamics Technical Director and aeronautical engineering student on the PMF team. "The 3DEXPERIENCE platform solutions accompany each design phase of our prototype: project management, design, simulation and validation. For us, the platform is a solution that fully integrates the motorbike project."

The PMF team, now 120 students and growing, immediately harnessed the power of the 3DEXPERIENCE platform, leveraging its cloud-based collaboration capabilities with virtually no training. As one might imagine, the highly motivated students access the platform 24/7 from various locations. The platform enables each interdisciplinary group to select the applications they need, which means everyone leverages the same environment for product development. This translates into vastly more effective collaboration and less wasted time.

Participating in the PMF team is not required for their bachelor's or master's curriculum but is an additional undertaking. Therefore, passion and the desire to learn more about design, creation and simulation, now and in the future, are key to the team's dedication and success. Due to their academic schedule, which includes three years of bachelor's studies followed by two years of master's studies, students on the PMF team experience rapid turnover similar to that of major, dynamic consulting firms. However, sharing and tracking knowledge and internal best practices is not an issue when working within the 3DEXPERIENCE platform. From day one, all the data, past and present, is captured on the platform in one secure location that is easily accessible by new team members.

"Since our production is one-shot, the simulation aspect is fundamental for our team," Trani continued. "We conduct structural, dynamic, frequency, buckling, multibody and CFD analyses. For example, PowerFLOW was essential for us to assess the transient instability of the petrol prototype's aerobrake; fe‑safe was used for fatigue analysis of the transmission shaft; and each structural component was dimensioned using Abaqus for topological optimization, static, frequency and buckling analysis."

Engineering Victory Lap

Developing an aerodynamic airbrake device that disrupts airflow during braking is one of the PMF team's most significant achievements. This innovation increases drag, allowing the driver to brake later in turns without compromising efficiency on the straights.

"PowerFLOW was particularly useful in providing rapid transient simulation results as we developed the airbrake," stated Francesco Buffoli, head of CFD Analysis and aeronautical engineering student on the PMF team. "It also enabled us to simulate the entire prototype down to the smallest details, with a very time-efficient mesh generation process." "Furthermore, by analyzing PowerFLOW's results, we could identify flow separations precisely. This led to the development of C-wings on the sides of the fairings, which enhanced efficiency on straights. We also employed the Fluid Dynamics Engineer role on the 3DEXPERIENCE platform to conduct a parametric design study then validated by PowerFLOW simulations."

The PMF team functions much like an industrial company, with various departments responsible for distinct roles. The structures department, for example, focuses on optimizing designs to achieve a lightweight yet more functional design. They frequently use Abaqus for topology and sizing optimizations, leveraging it to achieve specific rigidity and weight goals iteratively. For more complex tasks, they use Isight. A stellar example of the team's success with these strategies is the nearly 50% weight reduction of the rear swingarm compared with its predecessor. The team's internal research into materials, which enhanced their ability to model composites with greater precision, made this significant improvement achievable.

The Power of Experience

The real-world experiences gained from the 2023 competition challenged the team members to be resilient as they learned to navigate new environments and adapt to diverse situations. Real-world experience not only reinforces learning but also helps students appreciate the relevance of their coursework. Beyond academic skills, the students get the opportunity to develop critical soft skills essential in any professional setting, such as communication, teamwork, problem-solving and time management.

"Participating in the competition was quite an emotional roller coaster," explained Federico Noli, lead aerodynamics designer and materials engineering and nanotechnology student on the PMF team. "Between the joy of finishing the prototypes on time, the exhaustion from the intense work in the days leading up to the race, and the happiness of taking part in an international competition, it was a whirlwind of emotions. If I could go back, I wouldn't change a thing because, despite the problems we faced, everything helped me gain experience and taught me how to handle various situations, whether simple or complex."

"The hard work was repaid with great results," said Francesco Prodi, lead fairings designer and energy engineering student on the PMF team. "The best moment of the weekend was the final electric race, where our bike, Tatanka, secured second place in the competition after starting from seventh. During the event, we inevitably faced some technical issues, but learning is the main goal of these competitions, and the difficulties we encountered will help us make some good steps forward with the next bikes. I feel very proud of what we achieved, and I will never forget the team spirit that permeated our hearts during those days."

Despite the PMF team's success in the 2023 competition, they faced many challenges, including unforeseen issues.

"We were dedicated to being competitive and well-prepared, with high expectations and a deep sense of pride in our work," said Guglielmo Fadiga, lead aerodynamics designer and mechanical engineering student on the PMF team. "Both of our prototypes achieved remarkable results. However, not everything went according to plan". "We encountered a couple of issues with our Petrol prototype that we couldn't effectively resolve, which meant that it didn't quite achieve the results we were hoping for. This experience overall taught me the importance of making realistic plans and considering every possible mishap. Despite the challenges, I am confident that this experience has made me a better engineer and a more resilient person. I will always remember this competition as a significant milestone in my development."

Racing Toward the Future

As the PMF team prepares for MotoStudent 2025, their evolution from an enthusiastic group of five mechanical engineers to a leading team in academic motorcycle competitions validates the effective combination of learning and practical experience. With the support of advanced product development technologies from Dassault Systèmes and other sponsors, the PMF team is enthusiastically preparing for the next event. The team continues to refine its designs, aiming for optimal performance and reliability as they prepare for upcoming races.

"Part of the preparation for the 2025 event is transferring knowledge to new student leaders, which we do on two separate channels," Ambrosini explained. "All the engineering concepts and research results are transferred by technical reports, while, to help the new student leaders understand how to succeed in their positions, we usually have a transition period when both the old and new leaders manage their work. " "The support we receive from Dassault Systèmes is unparalleled: In addition to allowing us to use all their services constantly, they willingly enable us to make the most of their tools. What we appreciate most about Dassault Systèmes' approach toward us is their openness to the continuous daily challenges we set for ourselves, especially at the simulation level. It is a powerful set of tools that allow us to have great computing power at our disposal."

The student leaders unanimously thanked PMF for enriching their educational journey. They highlight the invaluable practical skills they developed in CAD, simulation, and PLM —skills that complement their more theoretical regular studies. The student leaders unanimously agreed, "Thanks to this experience, we feel that we have truly completed our education, shaping us into fully fledged engineers ready to enter the professional world confidently."

Focus on Polimi Motorcycle Factory

Polimi Motorcycle Factory (PMF) team, established in 2015 by five mechanical engineering students in the Department of Mechanics at the Polytechnic University of Milan (Politecnico di Milano), is driven by a passion for motorcycles. The team was formed to participate in the MotoStudent International Competition, where universities worldwide compete in designing, developing, and manufacturing combustion engines and electric racing motorcycles. The competition culminates in a MotoStudent event at MotorLand Aragón in northeastern Spain, where motorcycles undergo rigorous static and dynamic trials before racing.

This leading institution uses the 3DEXPERIENCE for Education

The Education Experiences, based on our industry-leading 3DEXPERIENCE platform, are the right ready-to-use packages to empower teachers with software, learning content, certification and community support.

Bring industries best practices into your classroom and prepare your students for their future careers by teaching them the right skills and keeping them engaged and excited at all times.