Pepperl+Fuchs

German industrial sensors specialist Pepperl+Fuchs wanted to replace its more than 100 different software systems with a single source for all development and product data in order to be at the forefront of advances in the field of virtual twins. To this end, the 3DEXPERIENCE platform was selected, enabling all data to be stored in a single source with full traceability, while improving efficiency, transparency and quality throughout the product lifecycle.

Pioneering industrial sensors with virtual twin experiences

What do train maintenance in Germany, rhino preservation in South Africa and sugarcane production in Brazil have in common? The answer: they all rely on automation technologies from German firm Pepperl+Fuchs.

With a rich history in process automation that stretches back nearly 80 years, Pepperl+Fuchs now has a range of 50,000 products. It is perhaps best known for its industrial sensors and explosion protection technologies, which have been successfully implemented in virtually all manufacturing environments, including refineries, wastewater treatment works and alternative energy plants.

One of its latest products, the R2000 2-D Laser Scanner, includes seven printed circuit boards, each with different embedded software, firmware and hardware. One of the scanner’s many applications is tunnel maintenance. It can be attached to a vehicle, which then drives through the tunnel to detect the finest cracks, dirt or other structural anomalies with millimeter precision.

Challenge

Pepperl+Fuchs’ future vision is to fully digitalize its existing processes so that it can improve efficiency, transparency and quality right across the product lifecycle. By embracing a data-driven approach that sees data transformed into a common format, it hopes to build the foundation for virtual twins. This will support its customers as they can maximize data from real world industrial systems and mirror those systems in 3D in the digital world.

To achieve this Pepperl+Fuchs needed a single view of its data. However, until recently, its teams worked in silos with more than 100 different software systems. This approach made it difficult and time-consuming to collaborate and iterate efficiently.

It also wanted to improve the way customers accessed information including product content data, specifications, firmware updates, CAD geometry, compliance information, and more – data that has been accessed via QR codes.

The company sought a professional product lifecycle management (PLM) solution that could ensure the end-to-end flow of information across the entire innovation chain and serve as a digital link between its data silos. With a single source of truth, everyone – including customers – could make better business decisions. In the future, it is hoped that the retrieval of this data could be automated and made available in an overall system context.

Choosing the 3DEXPERIENCE platform on the cloud offered investment security. We liked the platform’s data management and archiving capabilities, which could cover multiple functions. We also were impressed by its unique data model and sleek, modern interface with a clear focus on collaboration. Ultimately, Dassault Systèmes is a powerful company that is focused on the future. That was very attractive to us.

Solution

Pepperl+Fuchs recognized Dassault Systèmes as a leading provider of software-as-a-service product lifecycle management (PLM) solutions. It was impressed by the 3DEXPERIENCE platform on the cloud’s ability to integrate people, processes, product data and systems so that it could not only manage its products throughout the whole lifecycle, but also securely share data with other stakeholders along the value chain without compromising its intellectual property. It also appreciated how the cloud enables fast deployment of the ‘out of the box’ solution and global scalability in accordance with local legislation.

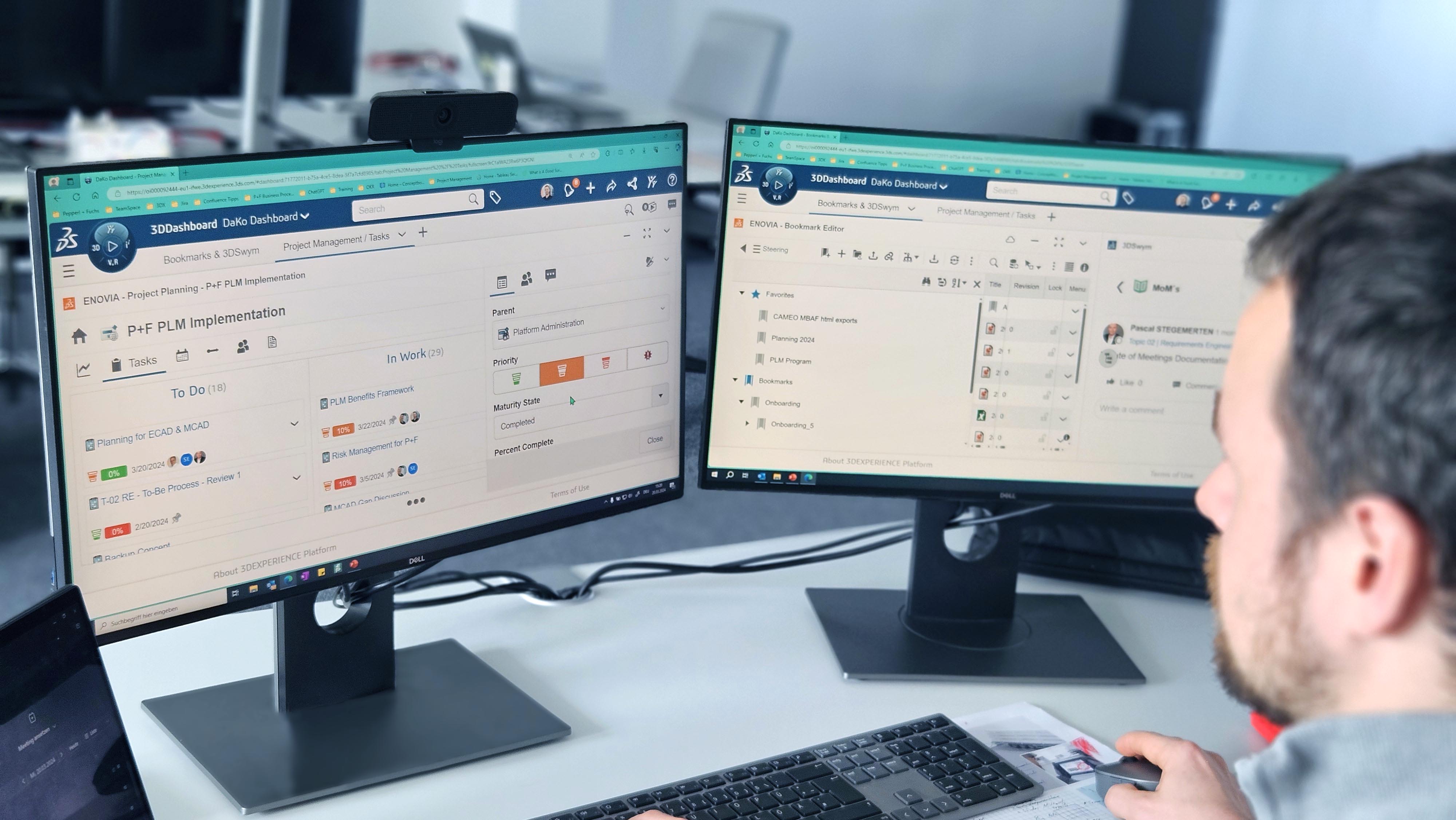

Following a successful initialization stage involving 200 colleagues from 17 departments, Pepperl+Fuchs rolled out first licenses of the 3DEXPERIENCE platform to 50 users for validation. Additional phases will soon see its entire innovation chain, spanning 2,500 users, leveraging the solution.

Benefits

The 3DEXPERIENCE platform on the cloud has fulfilled all the criteria set out by Pepperl+Fuchs and, following full rollout, is expected to deliver multiple benefits. Implementation requires no customization and will therefore be fast and simple, allowing the company to quickly take full advantage of the solution, and have the confidence that it will benefit from future updates in functionality.

Business decisions will be based on the same data and many manual steps and iteration changes will be eliminated, reducing the propensity for error. First analysis show that Pepperl+Fuchs was able to decrease the complexity in engineering change management to an eight of its former size and to increase digital continuity and traceability by seven times and compliance requirements are expected to be met with greater ease.

Pepperl+Fuchs and Dassault Systèmes have recently entered a strategic partnership that will see the two companies collaborate on business models for the digital economy. This marks the start of an exciting future. The full rollout of the 3DEXPERIENCE platform on the cloud will drive future data-driven business models, enabled by advances in virtual twins, sustainability, model-based working and data-driven collaboration.

Pepperl+Fuchs is also contributing to the international Manufacturing-X initiative, which aims to create a digitally networked industry that can drive sustainability, resilience and competitiveness. Key to this will be the adoption of the Asset Administration Shell – a standardized data model that enables physical assets to be modeled and managed in a digital environment. The 3DEXPERIENCE platform on the cloud will support Pepperl+Fuchs to facilitate smart innovation and allow it to quickly adopt new AI-based applications in the future.

Discover more about the Digital Equipment Continuity industry solution experience.

Focus on Pepperl+Fuchs

As one of the leading companies in the automation industry, Pepperl+Fuchs has developed several groundbreaking technologies that have earnt its reputation as a global pioneer. The company is based in Mannheim, Germany, and offers a comprehensive portfolio of applications for both factory automation and the process industry. At the same time, Pepperl+Fuchs continues to drive forward-looking technologies, paving the way for its customers to meet the upcoming challenges of Industry 4.0.

For more information: https://pepperl-fuchs.com