OSSTEM IMPLANT

The company adopted the 3DEXPERIENCE platform and its License to Cure for Medical Device industry solution experience to accelerate the delivery of innovative, safe, and fully-compliant medical devices.

A happy smile

As people live longer and interest in health and aesthetics increases, implants have become an essential form of dental therapy around the world. Founded in 1997, Korea’s Osstem Implant, Asia-Pacific’s number one dental medical device manufacturer with a 45% share of the Korean market and a 36% share of the Chinese market, also ranks fifth in the world for the production of implants. This is due to important investments in research and development that have resulted in quality implants and related dental technology.

Because various types of dental implants are required depending on patients’ oral cavity structure and dental needs, Osstem Implant develops a wide range of implants, such as ultra-wide or short implants as well as custom fit abutments. Osstem Implant’s top-notch technologies include ultra-precision processing, surface treatment and cleaning along with its strict quality control processes throughout product development and manufacturing, which contribute to the competitiveness of its product offering. The company strives to deliver products that will leave every patient with a happy smile.

The key to Osstem Implant’s competitiveness is R&D. In the implant market, where consumer needs are very specific and diverse, the company needed a flexible yet robust information management infrastructure that can adapt to changing demands. Osstem Implant believes that working with the right solutions can improve product development and production processes, which in turn, will enable the company to successfully respond to this need for customization.

Compliance with innovation

Osstem Implant’s vision is to become the world’s number one implant company by 2023. While pursuing this challenge, the company also has to meet its product-compliance responsibilities. Its products have to comply with national and international requirements if Osstem Implant expects to gain global market share. “Rising scrutiny around healthrelated products forces us to devote much of our R&D to regulatory activities rather than on developing new products,” Kim Tae-yong, Head of Information Systems Management, Osstem Implant, said. “Gaining global market share calls for diversification and rapid delivery of innovative products to the consumer. Our regulation activities should not stand in the way of that. Satisfy regulatory requirements yes, but not at the expense of new product development.”

In September 2015, Osstem Implant completed the first step toward streamlining its regulatory compliance processes in accordance with the U.S. Food and Drug Administration’s guidelines, by establishing a unique device identification (UDI) system to identify medical devices throughout their distribution and use. This would enable the public to search for information on the device in question. The benefits are improved patient safety and device traceability.

The UDI comprises several types of information including manufacturing date, expiration date, lot and serial numbers. The UDI, individually generated for each product, is linked to the company’s internal Enterprise Resource Planning (ERP) and label production system, and Osstem Implant directly submits the information to the FDA’s GUDID (Global UDI Database).

However, the UDI information submitted to the FDA was not connected to the design and licensing information at Osstem Implant. Therefore, if wrong UDI information was entered, the system could not accurately track it. Moreover, the company needed to frequently generate additional UDIs due to the wide variety of product groups, but were not as fast as they would have liked. Osstem Implant needed to implement a solution that could manage and submit UDIs in a more streamlined manner.

With Dassault Systèmes’ 3DEXPERIENCE platform we enhance business efficiency and develop higher-quality medical device products that comply with international regulations.

3DEXPERIENCE accelerates delivery of innovative, safe and fully compliant medical devices

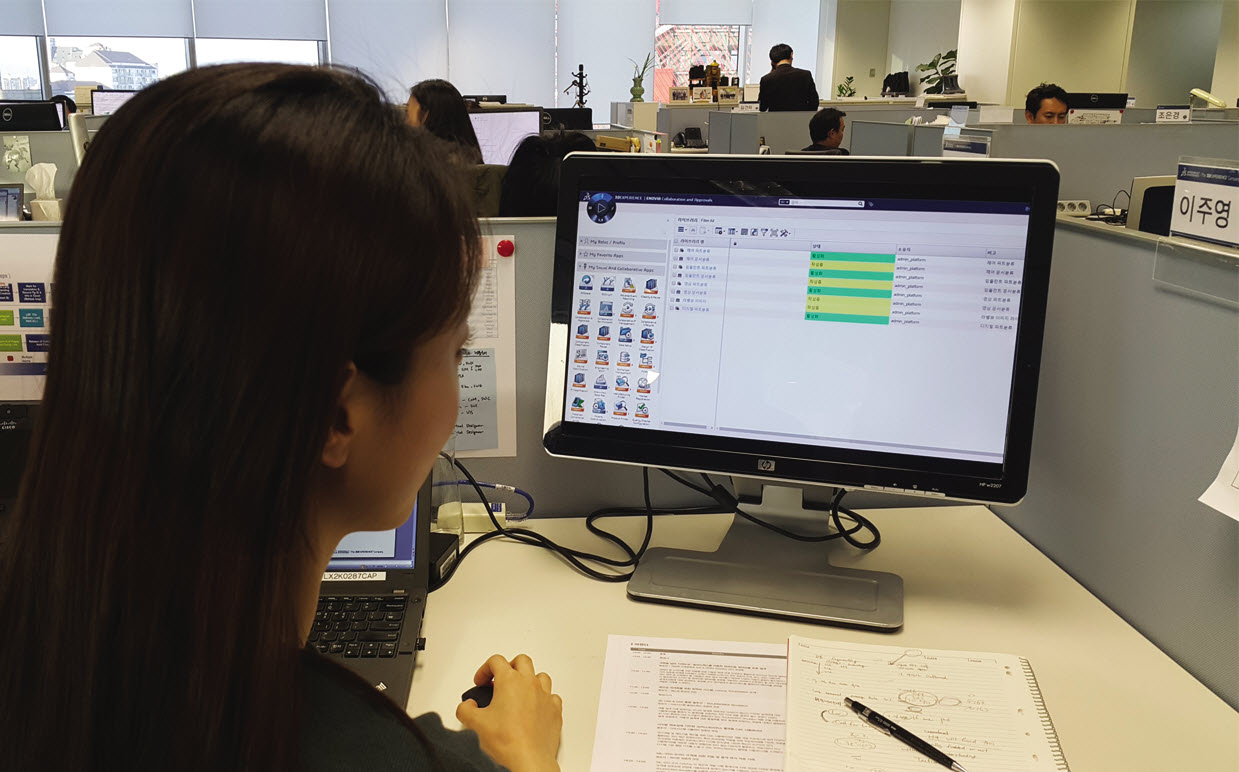

To globally manage UDI information, design change information and quality control information, Osstem Implant chose Dassault Systèmes’ 3DEXPERIENCE® platform and its License to Cure for Medical Device industry solution experience. Exclusively developed for the life sciences, License to Cure for Medical Device delivers a collaborative, integrated business framework that helps accelerate the delivery of innovative, safe, and fully compliant medical products. It helps optimize device quality and compliance since it offers integrated management of previously disconnected processes and data. This end-to-end solution supports a company’s quality system and regulatory compliance ISO-regulated design controls. It also supports FDA UDI HL7 SPL submission. SPL is a document markup standard approved by Health Level Seven (HL7) and used by the FDA to exchange product information. With the 3DEXPERIENCE platform, companies have a single source of up-to-date product development data that is directly linked to quality and regulatory information. In the face of increased regulatory scrutiny, License to Cure for Medical Device helps companies efficiently manage regulations and reduce time to market.

Immediately after implementing License to Cure for Medical Device , Osstem Implant began to perceive real benefits. Processes that were previously managed separately are now connected and integrated in the system and in compliance with the different FDA regulations. These include bill of materials (BOM) and device master record (DMR) management, management of certification documents and UDIs, document versioning, requirements management, quality control, and management of environmental substances. Integrated UDI management also improves product quality control. Since it is easier to track and manage all processes, if a product quality problem is reported, it is now possible to track both the DI (Device Identifier) and PI (Production Identifier) simply by checking the UDI of the product in question. Tracking these identifiers helps improve patient safety, modernize surveillance of devices, and simplify medical device innovation. As a result, Osstem Implant can now respond to quality issues in a timely manner. “UDI management is an important aspect of quality control and a prerequisite to our global expansion” Kim Tae-yong said. “With Dassault Systèmes’ 3DEXPERIENCE platform we enhance business efficiency and develop higher-quality medical device products that comply with international regulations.”

Pursuing the top spot in global market share

Osstem Implant now has the infrastructure to manage information related to UDI and to promote collaboration between the various departments, such as quality, production, licensing and R&D. “We are on a path to realizing our vision: to become the No. 1 implant maker in the world,” Kim Taeyong said. “We plan to increase the use of the 3DEXPERIENCE platform in the future, to further improve business efficiency and product quality.”

Focus on Osstem Implant

Dental medical device manufacturer

Products: dental implant solutions, dental materials, pharmaceuticals

Employees: 2,730

Revenue: $305m (2016)

Headquarters: Seoul, South Korea

For more information www.osstem.com