NGK Spark Plug Company Limited

NGK Spark Plug Co., Ltd. adopted Dassault Systèmes 3DEXPERIENCE platform to manage the company’s engineering data and to link its Design Information Department with worldwide production sites.

PROTECTING THE ENVIRONMENT

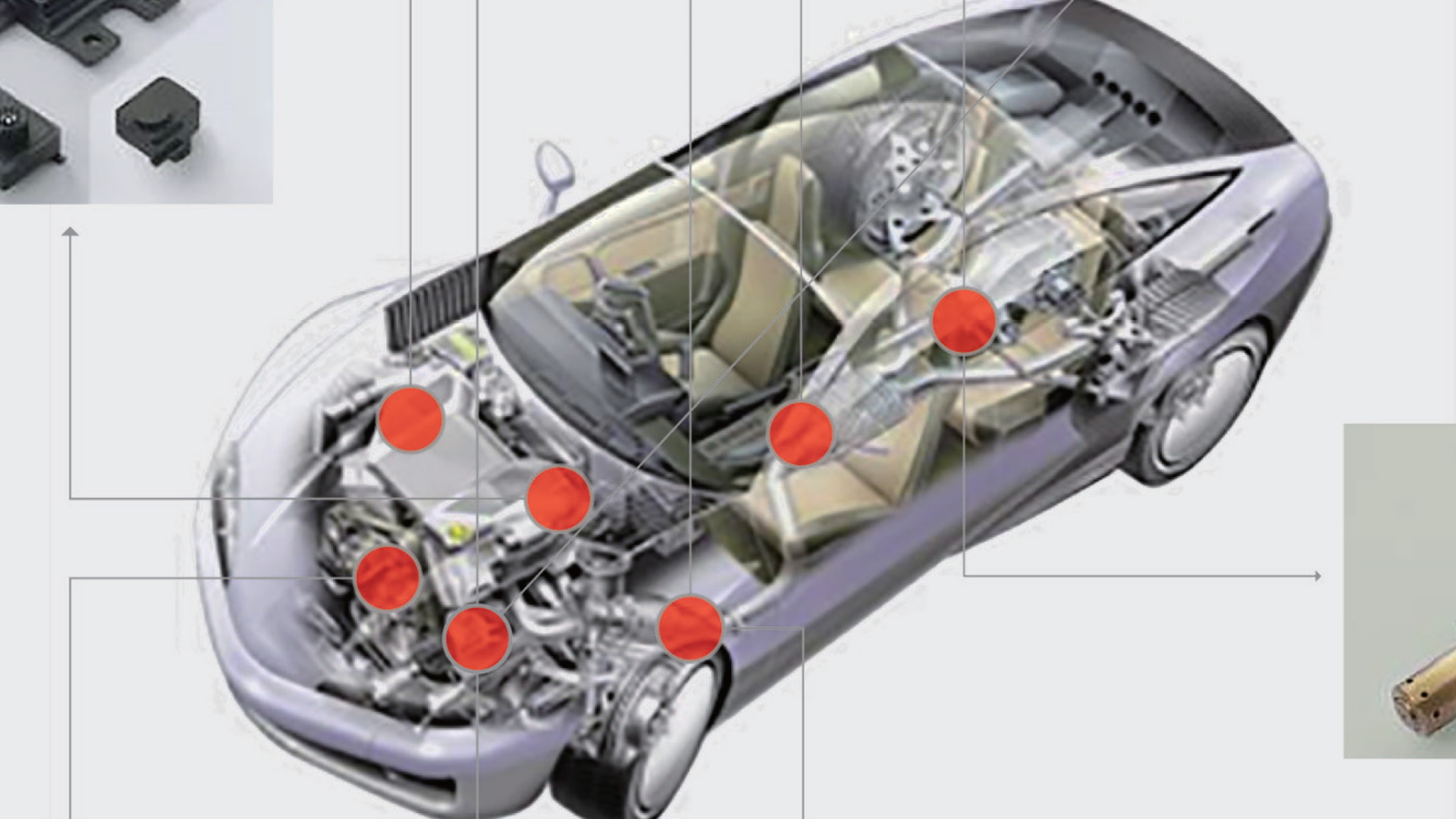

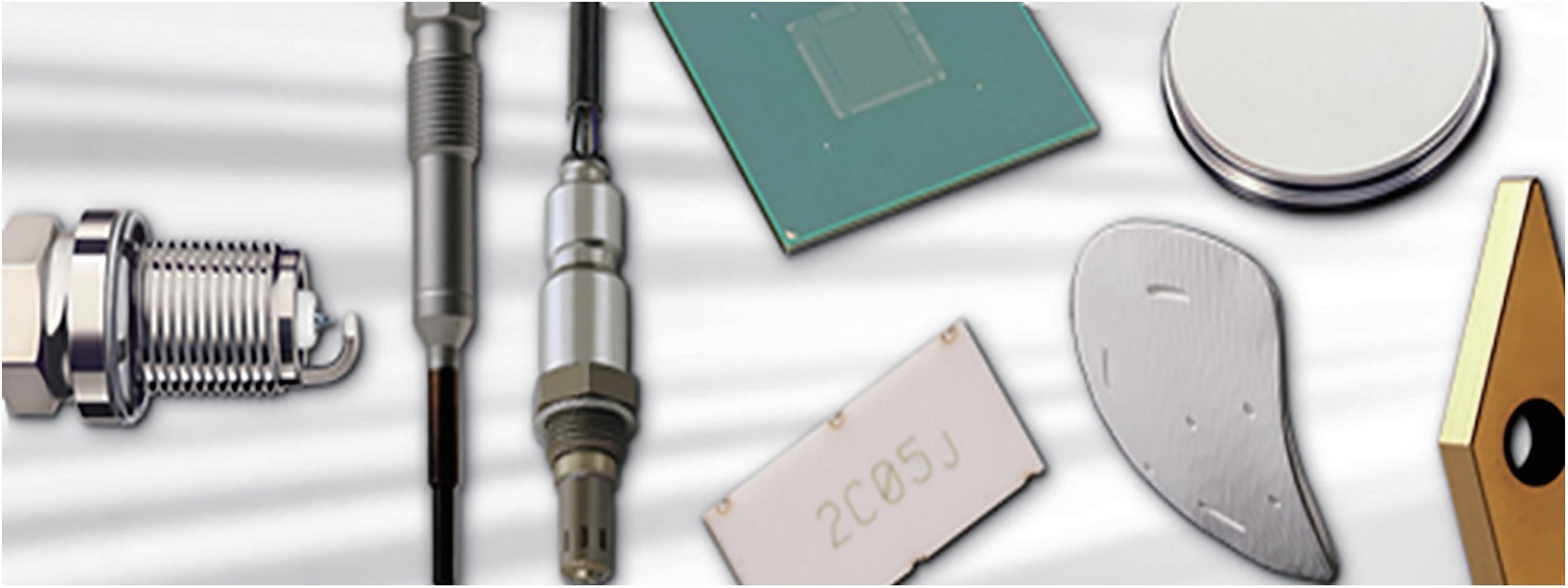

NGK Spark Plug Company Limited develops a wide range of products that include automotive parts for internal combustion engines and technical ceramics. For the automotive industry, the company develops sophisticated ceramics products that promote driving pleasure and improve safety while respecting the environment. Along with spark plugs, NGK Spark Plug Co., Ltd. also develops oxygen, temperature and knock sensors, which improve performance and eco-efficiency of the automobile. The company’s spark plugs have been used by almost all automotive manufacturers domestically and worldwide, and the company is proud of its top class global market share for both spark plugs and oxygen sensors for exhaust-emission purification systems.

NGK Spark Plug Co., Ltd. sensors, which purify exhaust emissions and reduce fuel consumption, are developed in the company’s Sensor Engineering Department. The oxygen sensor was developed to purify exhaust emissions from gasoline-engine vehicles only, and then its know-how was applied to diesel-engine vehicles and motor cycles, further contributing to environmental protection around the world.

GOING GLOBAL

In the l990s, to support the production of all types of automotive sensors, NGK Spark Plug Co., Ltd introduced a drawing management system using an IT network, followed by sales and production management systems. However, the drawing management system was not sufficiently coordinated with other systems that generate the company’s drawing data, which hampered its global business development. Factors such as an increase in automotive sales, a growing number of new products, and the expansion of NGK Spark Plug Co., Ltd.’s production facilities overseas complicated the timely issuance of product drawings to each production site. In addition, when a change to a key part occurred, it would lead to extensive changes to related drawings. However, no existing system could quickly issue a large number of drawings. And, while a single sensor product requires multiple drawings, the control of these drawings and its bills of material (BOM) was not unitarily carried out, which complicated the overall management of the data. Furthermore, and for that reason, BOM information on the drawings often did not match production BOM information at the manufacturing site because coordinated with the company’s new production system.

We adopted the Dassault Systèmes 3DEXPERIENCE platform, which enables a uniformed control of design information.

ESTABLISHING A FOUNDATION FOR DESIGN

To address these challenges, NGK Spark Plug Co., Ltd. introduced the 3DEXPERIENCE® platform and its ENOVIA V6 application, which is seamlessly integrated with CATIA V6, NGK Spark Plug Co., Ltd.’s core CAD application. By introducing the 3DEXPERIENCE platform, NGK Spark Plug Co., Ltd. created a next-generation engineering data system (EDS) that will support modularity through the unified management of all design data. In line with this strategy, the company upgraded its CAD system to CATIA V6, optimizing design efficiency by taking advantage of the application’s capability for modular design.

POWERFUL SUPPORT FOR SPEEDY GLOBAL BUSINESS

The EDS, which the company is establishing on the 3DEXPERIENCE platform, will support the engineering development process, by providing the entire NTK group with access to production data and linking customer demands with customer satisfaction. “Through this EDS, we aim to enhance collaboration with the production management system and enable the speedy transmission of design data on a global scale in a secure environment,” Masashi Ando, Manager in the Sensor Engineering Department explained. “With this system, we expect a quicker response from our production sites when faced with an increase in production.” Ando continued, “The core requirement for our EDS is to precisely connect all the data in different forms related to design and drawings, allowing for prompt extraction and distribution of all necessary product information. In addition, we needed to facilitate the design change and overall design process. To achieve this goal, we adopted the Dassault Systèmes 3DEXPERIENCE platform, which enables a uniformed control of design information.” All unitarily managed and stored information for producing a single sensor product, including design drawings, CAD design data, and BOM data saved in different file formats are easily shared among production departments and affiliated departments both in Japan and overseas in the 3DEXPERIENCE platform.

The EDS ties all document and drawing information to each specific product number. It also links information of manufacturing process types, as well as packaging data to specific product numbers. This allows a unified search and view of the information, which results in increased productivity.

In parallel with establishing the EDS, NGK Spark Plug Co., Ltd. is also transitioning from its major 2D design process to 3D with CATIA V6 for modular design, which enables rapid design reconfigurations. For example, when designing a sensor, a variety of specifications such as the size of a part to attach to and the type of connector to be used are assorted with specifications of basic sensor characteristics. Standardizing these variations or modularizing them can simplify the process of re-combining existing parts into a new design that perfectly meets customer requirements.

Focus on NGK Spark Plug Co. Ltd.

Manufacturer of sensors for automotive, spark plugs internal-combustion related products, technical ceramics and applicable products.

Products: spark plugs, glow plugs, sensors, semiconductor components, electronic components, medical products, industrial components and cutting tools

Employees: Non-Consolidated: 5,809 (March 2014); Consolidated: 12,760 (March 2014)

Headquarters: Nagoya, Japan

For more information www.ngkntk.co.jp