Monceau Automobiles

Converting classic Mercedes-Benz into 100% electric cars, Monceau Automobiles leveraged the Efficient Multi-Energy Platform industry solution experience to gain 3D design precision and manage its complex repository of product data.

Converting classic Mercedes-Benz into electric cars

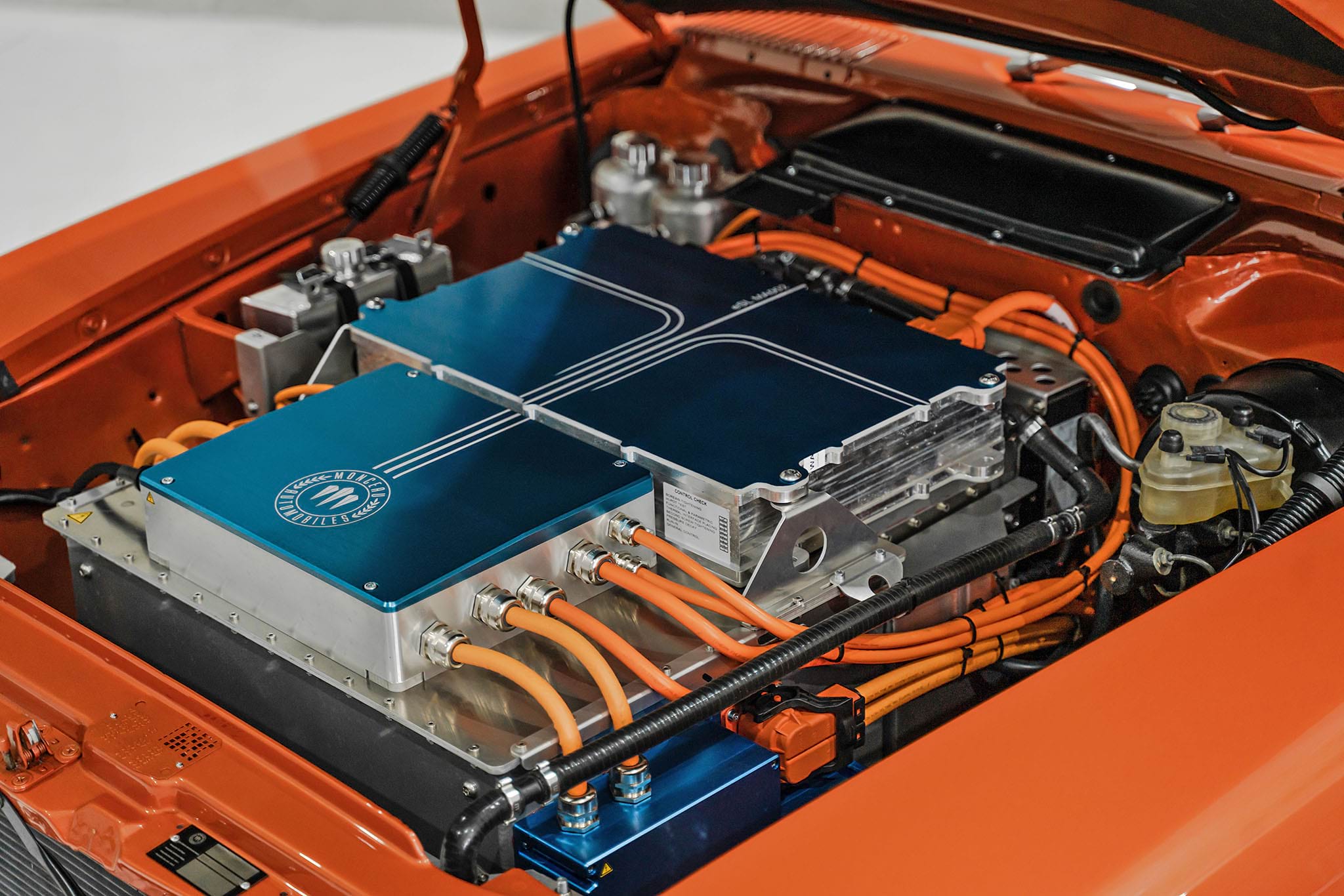

For many families, classic cars are a treasured heirloom – a prized possession passed down through generations. Combining the history and emotion of iconic Mercedes cars, along with the exceptional driving experience inherent to electric powertrains, Belgium-based startup Monceau Automobiles has been able to take the timeless design of a classic car to another level.

With multiple years of experience in Formula E and other electric engineering projects, Monceau’s team consists of classic car experts, bodywork specialists, battery and electrical engineers as well as software engineers and mechanical designers.

“We specialize in converting classic Mercedes into 100% electric cars,” said Roel Pollen, Monceau’s co-founder and managing director. “Our highly skilled professionals enable us to complete the end-to-end restoration process in-house. As well as completely overhauling the internal mechanical parts, we can also restore the chassis to showroom-new condition, taking care of body repair, welding, pre-paint preparation and final paint application.”

To design its products efficiently and ensure its multidisciplinary teams can work together most effectively, Monceau requires best-of-breed technology – and this has been with Dassault Systèmes’ solutions.

Monceau Mercedes-Benz iconic electric cars conversion and restoration

Retrofitting iconic cars in an exacting market

No two days are the same at Monceau. Every customer has a different vision for their dream conversion – so every project is completely individual.

“Every restoration project begins with the documented dismantling of the vehicles so that the traditional engine and fuel system can be replaced with a fully electric drivetrain and adequate battery packs,” Pollen said. “The suspension, axles, brake system and other parts are also replaced. But these cars were never intended to have electrical drive – so converting them can often bring challenges. We need to make sure all new components can fit within the existing frame.”

This isn’t the only challenge. Monceau needs to manage a significant amount of product data and information for every component that is designed and produced in-house. Doing this using spreadsheets can be error-prone and often leads to the duplication of data.

At the same time, the company also has to deal with a growing number of suppliers in Switzerland, Germany, Belgium, The Netherlands and the US. This creates an additional complex web of product data which requires proper management.

“We work with a lot of data from third parties and have a lot of it in-house,” said Alizé De Vroey, Monceau’s project manager. “We’ve found it very difficult to collect all that information in one place.”

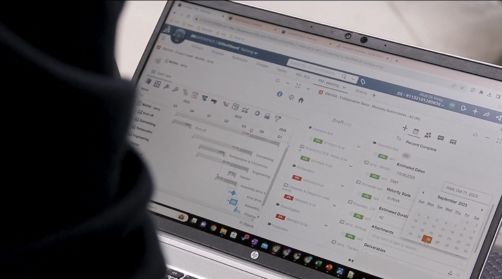

Monceau Automobiles engineers use CATIA for design and ENOVIA for project and data management on the 3DEXPERIENCE cloud-based platform.

A cloud-based solution for fast rollout

Recognizing that it needed a new approach facilitated by an industry-leading design and product data management solution, Monceau turned to local partner Cadmes for help. Understanding Monceau’s challenges, Cadmes suggested Dassault Systèmes 3DEXPERIENCE® for Startups offer and its full suite of cloud-based industry-standard solutions, including the latest version of CATIA for design, as well as ENOVIA for project and data management.

Since this is a cloud-based implementation, rollout was fast. Cadmes provided three days of training on CATIA and has been on hand to offer support at every stage of the process.

“Moving from CATIA V5 to the 3DEXPERIENCE platform on the cloud has been made a lot easier by Cadmes,” said Nicolas Olliver, a CAD engineer at Monceau. “We have set up a direct channel of communication that allows me to ask any question and get a quick answer that solves my problem.”

A single platform for multidiciplinary collaboration

The conversion process begins with a 3D scan of the vehicle. Then, using CATIA, Monceau’s engineers can integrate all the various components and complex surfaces.

“We can see the positioning of each part and make any adjustments before we make the physical restoration,” Olliver said. “That saves us a lot of time during the whole design phase and gives us a finished product that is of a higher quality.”

Now that all Monceau employees work in the same software environment and can access a single source of truth, internal collaboration is more efficient. That’s because there’s no longer any time spent emailing back and forth and none of the complexities that come with managing a file-based system. For example, a collaborator’s task can directly be linked to the design file from another, which makes it easier to work together.

Confident that the most up-to-date version of a design is accessible by everyone, the risk of errors is significantly reduced. And because the platform is hosted on the cloud, employees can securely access files from anywhere with a Wi-Fi connection.

Leveraging the benefits of ENOVIA for project and product data management will enable Monceau to bring together internal and external component data into a single comprehensive parts catalog. This will avoid to duplicate information and will allow employees to quickly source parts.

“Using ENOVIA, we can build our knowledge base and document everything,” De Vroey said. “We also hope to communicate with suppliers directly in the platform.”

There are many Monceau conversions on roads already, but Pollen hopes the Dassault Systèmes’ solutions will help the company scale up the number it can complete and boost innovation as a result.

“My dream for the future is that wherever I am in the world, I will see one of the beautiful cars we have built; and that after 20 years or so, they will still be driven,” Pollen said. “That, for me, would be a real crowning achievement.”

Discover more about the Efficient Multi-Energy Platform industry solution experience.

Focus on Monceau Automobiles

Monceau Automobiles retrofits Mercedes-Benz classics with modern electric vehicle technology to create beautiful electric classic cars. The company selects the best components from high-end suppliers from Switzerland, Germany, Belgium, The Netherlands and the US. All donor cars are selected carefully based on a customer’s individual preferences and chosen model.

For more information: https://monceau-automobiles.com

Focus on Cadmes

Established in 1991, Cadmes aims to help companies succeed in a rapidly changing industry using automation and optimization solutions. Recognizing that new technologies can only create opportunities if they are used successfully, Cadmes focuses not only on the delivery of smart software, but on providing full support for businesses looking to transform. By implementing proven working methods, process optimizations and standards, Cadmes succeeds in making companies more agile, innovative and competitive.

For more information: https://www.cadmes.com/