MerConcept

Innovative by nature, MerConcept pushes the limits of ocean racing by harnessing the aerodynamic power of the SVR-LAZARTIGUE trimaran using 3DEXPERIENCE on the cloud and contributes to rethinking sustainable mobility on oceans.

(Photo © Guillaume Gatefait)

SVR-LAZARTIGUE, a boat built to fly

Take a handful of the world’s most innovative sailing machines and race them in brutal winter conditions across the North Atlantic Sea and you have the Transat Jacques Vabre, one of the most elite and challenging yachting races on the planet. The largest class of boats to compete in the grueling 7,500 mile-ocean sprint are the 32-meter long Ultim trimarans, giants of the seas that reach incredible speeds to literally fly over the surface of the water.

In its debut race, newcomer SVR-LAZARTIGUE crossed the finish line in 16 days 9 hours 46 minutes and 11 seconds to take second place. When French sailing duo François Gabart and Tom Laperche set out on the double-handed transatlantic race from Le Havre to Martinique, their main goal was simply to reach the other side safely; a podium place surpassed all expectations.

Two and a half years in the making, SVR-LAZARTIGUE was developed and built by Gabart’s own company, MerConcept, the offshore racing specialist that was also responsible for the M100 Ultim trimaran – winner of the Transat Jacques Vabre, the English Transat, The Bridge, and holder of the round-the-world solo record in 2017 (manned by Gabart).

“MerConcept is about passion,” said François Gabart, founder of MerConcept and SVR-LAZARTIGUE skipper. “It’s a passion for the sea, the wind, and the waves – harnessing their power to go ever faster. It’s a passion for boats, which have made ocean racing my professional career. After 30 years of sailing, I still marvel at being able to roam the oceans at full speed.”

Innovative and competitive by nature, MerConcept’s success is built on its ability to combine deep industry knowledge and the latest technological capabilities to create unique and revolutionary designs. The company’s partnership with Dassault Systèmes plays a critical role in this, delivering the solution it needs to develop the boats from start to finish, and better understand and anticipate their behavior at sea.

“To successfully carry out a project like SVR-LAZARTIGUE, in addition to passion, you need to have knowledge and experience of the boat,” said Antoine Gautier, design office manager at MerConcept. “Our close collaboration with Dassault Systèmes began in 2011, when we built François Gabart’s first IMOCA-class yacht. We used CATIA to design the boat and all composites parts. We have since moved to the 3DEXPERIENCE platform on cloud and our level of expertise with the solution has significantly evolved.”

Collaborating on a virtual twin

SVR-LAZARTIGUE is the result of a mammoth engineering endeavor bringing together expertise from all around the world.

“To design and build a boat like SVR-LAZARTIGUE, it takes around 150,000 hours of work, involving more than 150 external collaborations,” said Thomas Normand, CEO of MerConcept. “There’s a lot of collaborative work involved, synchronizing tasks, moving from the design phase to the construction phase.”

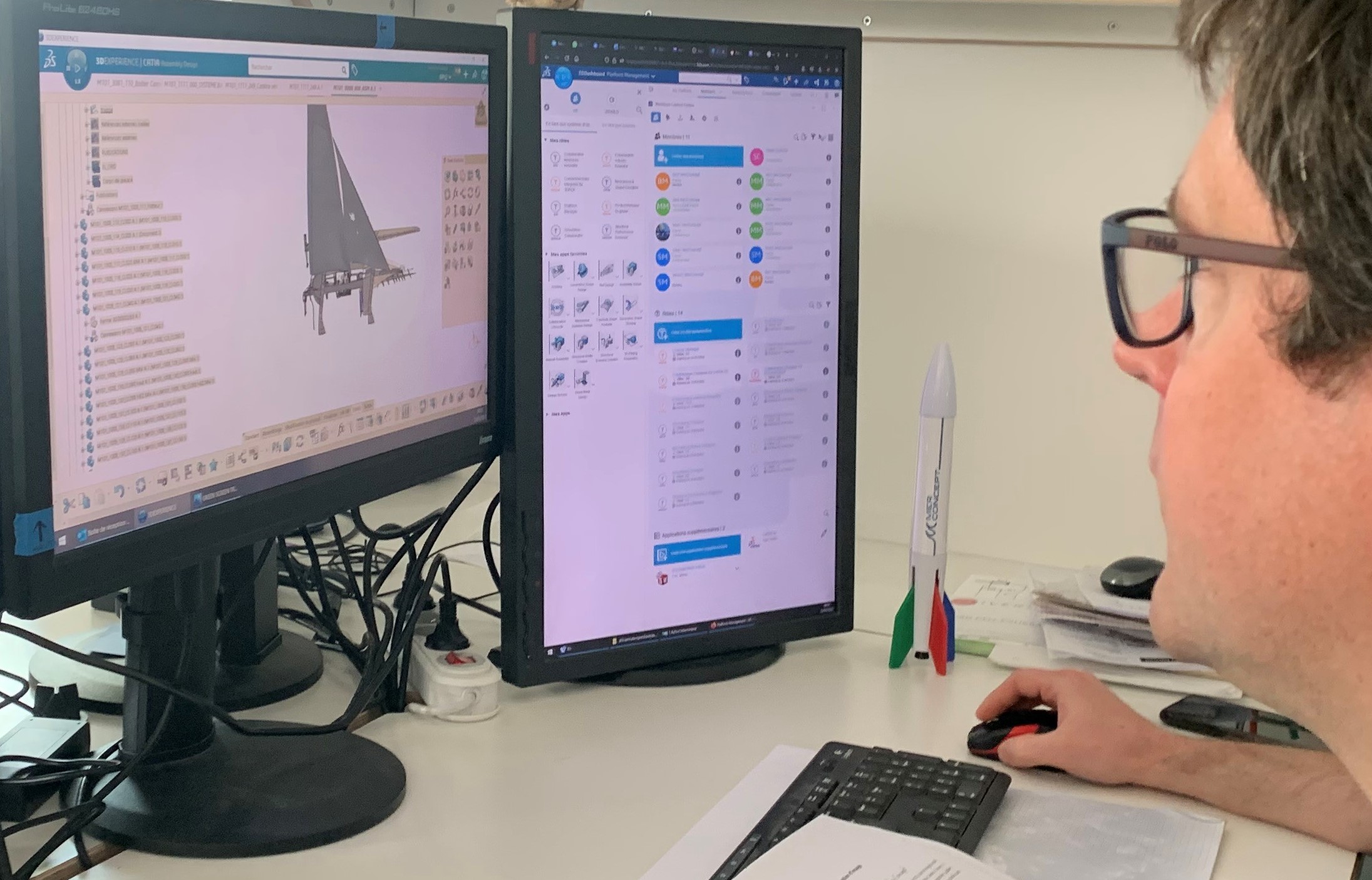

Before moving to the 3DEXPERIENCE platform, it was challenging keeping everyone up to date with progress and ensuring they were all working with the latest version. Now, MerConcept has a common data environment, where everyone can work together on the same 3D model – critical for orchestrating all participants and successfully bringing the boat from concept to reality.

“If we focus on the design phase, we need to work with tools that are as collaborative, intuitive and easy to use as possible,” Normand said. “Using ENOVIA, the construction and design phase is as smooth as it can be, and that we can support effective information sharing among all the different parties.”

With multiple people working on the design at any one time, ENOVIA helps to ensure that technical modifications are correctly implemented, and all affected stakeholders are notified.

“For me, the advantages of the 3DEXPERIENCE platform on the cloud are that we can all interact on the same model,” Gautier said. “Everyone needs to be up to date, so that everyone can see what has been done, and avoid interference issues.”

MerConcept’s 3D model of SVR-LAZARTIGUE is a true virtual twin of the physical boat, available in the cloud. This virtual twin is a physically accurate 3D model of the trimaran and its systems viewed in the context of its environment at sea through simulation. It allows the team to virtually design SVR-LAZARTIGUE, complete with all system behaviors, and test it in limitless scenarios.

“The virtual twin also allows all relevant stakeholders to access the current model in real time and act on the part or the system that interests them,” Normand said. “Different teams can ‘speak the same language’ and know that what they’re working on is directly linked to what is actually going on in the workshop.”

The virtual twin allows all relevant stakeholders to access the current model in real time and focus on the part or the system that interests them.

Refining the design at sea

MerConcept uses the virtual twin of SVR-LAZARTIGUE to not only refine its designs but manage the boat throughout its lifecycle and make constant improvements based on data collected from tests and races.

“The virtual twin must be able to evolve over time because, once the boat is in the water, it has a lifecycle of between four and six years corresponding to the next races,” Gautier said.

MerConcept’s performance department acts as the interface between the boat’s navigation and the design office, which constantly updates the virtual twin.

“Every time we sail, train or race, a lot of data is sent back to MerConcept,” Gautier said. “This is processed and analyzed, and sometimes results in modifications to parts, systems, or even the structure of the boat.”

The fact the 3DEXPERIENCE platform is cloud based has been crucial for collecting and retrieving data when the boat is at sea.

“Thanks to the cloud, we are able to connect from anywhere with an internet connection,” Gautier said. “When we’re on the water, we can access the 3DEXPERIENCE platform and see the boat’s plans and 3D model – critical if we experience any damage or otherwise. We can read the plans and try to understand in more detail what has happened. Thanks to this system, we can bridge the gap between virtual and reality.”

From hydrodynamics to aerodynamics

Ultim trimarans are the fastest and most advanced foiling offshore designs ever created. They literally fly across the water, which is why in addition to focusing on foil developments and hydrodynamic improvements, Gabart’s team puts as much emphasis on aerodynamics. While other Ultims have retro-fitted parts to improve aero efficiency, SVR-LAZARTIGUE was designed for flight from the beginning.

“In the past, architects worked on the drag of the hulls to optimize the speed of the boat,” Gautier said. “Now, we’re working on the aerodynamics to go even faster. With the foils we use today – which are the equivalent of an airplane’s wings – boats levitate above the water. It’s like a flying carpet; it doesn’t make a sound. It’s an extraordinary sensation. Once you’ve experienced it, you never want to go back to a classic boat.”

One of SVR-LAZARTIGUE’s unique design features is the cabin, which sits below the water so the roof is almost flush with the main arms and trampoline for minimum drag.

“The aerodynamic elements we’re focused on are the sails, which drive the boat, and the whole structure: the hulls, crossbeams, protective pods, helm stations and much more,” Gautier said. “These are all the components facing the wind and that act as a brake.”

Every single design enhancement goes towards making the boat even more streamlined.

“These boats sometimes go at speeds of over 100 kilometers per hour,” Normand said. “We have been working for years in ocean racing, on everything that happens underwater. And now, thanks to Dassault Systèmes, we’re able to focus on what happens above the water too.”

Boosting racing performance with simulation

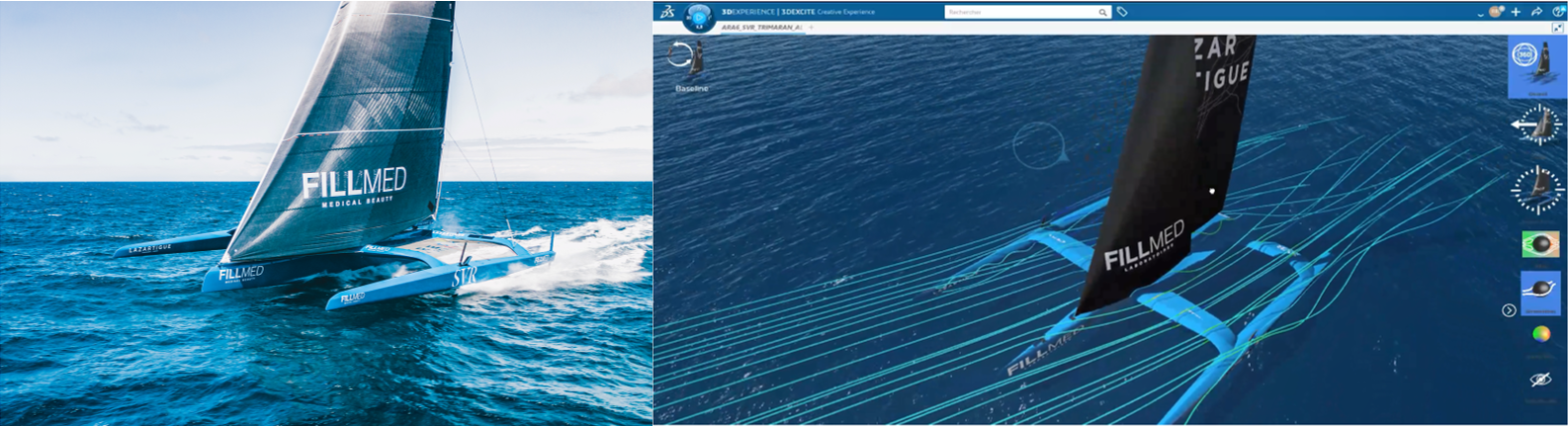

Working with French technology partner CT Mer Forte, MerConcept asked Dassault Systèmes’ SIMULIA team to help create and analyze scenarios that would enhance the aerodynamics of the trimaran.

All MerConcept’s simulations are executed using SIMULIA PowerFLOW technology, a transient Lattice Boltzmann-based computational fluid dynamics app that enables the team to perform simulations that accurately predict fluid flow physics of detailed geometry for given operating conditions. MerConcept has then been able to evaluate three optimization scenarios to gain a clear idea of what needs to be changed in the trimaran’s design to improve its performance.

“Thanks to SIMULIA and the 3DEXPERIENCE platform, we have superb depictions of where we can see the streamlines illustrating the air deforming around the trimaran,” Gautier said. “We have qualitative images that allow us to identify the points that cause drag. These visual simulations are very useful and reliable. As a result, we discovered drag marks that we had previously not identified, especially around the rear beam, and this prompted us to modify the fairing geometry.”

The simulation results have already helped MerConcept to achieve impressive aerodynamics enhancements. It will be applying further recommendations for future competitions.

“Through our work with SIMULIA and their experts, we were able to make significant gains in the boat’s aerodynamics, which I hope will be reflected in exceptional improvements in performance on the water,” Gautier said. “When we have put all the elements we have tested on the trimaran, we should achieve a 70% improvement in the aerodynamic drag. There is no other sector where you can make as much progress as this.”

Sustainable ambitions

Beyond racing, MerConcept is building on its ambition to harness its expertise in racing for the greater benefit of the global maritime industry. The company became an “entreprise à mission” (a French legal framework in which companies adopt specific sustainability goals) at the end of 2019 and set up a new research and development lab focused on broader marine applications.

“My deep desire is to enable this technological transfer from ocean racing to the maritime world,” Gabart said. “For this, we decided to structure a sustainable innovation laboratory, so all the amazing advances generated by these exceptional racing boats will serve the maritime industry. We want to enable a technological transfer from offshore racing and yachting to the transport of people and goods, moving towards sustainable mobility on the oceans.”

In particular, MerConcept will focus on developing concepts and prototypes that demonstrate the potential of wind energy and foil propulsion.

“We all need to make a huge effort to reduce our daily carbon impact,” Normand said. “That includes our daily transport. Our business is the sea, so we can be responsible for reducing our carbon impact on the oceans when we build boats and participate in races. But also, if we manage to collaborate with the shipping industry on projects that reduce their carbon impact and benefit our planet in the years to come, we’ll be very happy.”

Normand shared an example of a ferry project MerConcept is working on.

“Foils allow boats to lift themselves above the water and gain power and speed,” he said. “We are working on equipping a ferry, which will carry between 100 and 200 people, with these foils. It will be able to fly above the water and cut its energy consumption by half. This type of project is likely to emerge in the coming years.”

Backed by the power of the 3DEXPERIENCE platform, MerConcept is not only pushing the boundaries of what’s possible in ocean racing but helping to reinvent the very concept of marine transport to preserve the planet and protect the oceans.

“We have this extraordinary ability to cover thousands of kilometers using only wind force to make our boats fly at full speed,” Gabart said. “There is still so much to explore. Now more than ever, we must give meaning to progress so that the future remains full of dreams and promises.”

improvement in the aerodynamic drag

to design and build a boat like SVR-LAZARTIGUE

at the Transat Jacques Vabre race

Discover more about the Winning Bid For Sea industry solution experience.

Discover more about the Sea Boat Builder industry solution experience.

00:00 – 00:06

Antoine Gautier, Design Office Manager, MerConcept:

When you have experienced flying on a boat, it’s an extraordinary feeling and you cannot go back.

00:07 – 00:12

Thomas Normand, CEO, MerConcept:

We’ve been able to imagine and build many boats. We took part in many races. We are quite proud of our track record.

00:13 – 00:24

François Gabart, Skipper and Founder, MerConcept:

When you see what has happened, what we’ve been able to achieve, the potential of the boat, we believe that everything is possible for tomorrow.

00:25 – 00:53

Antoine Gautier:

Before, we sailed with hulls dragging in the water. Today, we fly above the water. Before, an architect had to work on the shape of the hulls to optimize the drag. Today, we have to work on the aerodynamics to improve the performance of our boat. This is our challenge. Thanks to 3DEXPERIENCE, we have great renderings where we can see the flow lines that we call streamlines. So, we see the air warp around the trimaran. We should achieve a 70% gain in the aerodynamic drag of our trimaran.

00:54 – 01:20

Thomas Normand:

For example, on the SVR-Lazartigue trimaran, it's just over 150,000 hours of work. It's a lot of collaborative work. We use the Dassault Systèmes suite mainly to be able to use the virtual twin, a kind of digital copy of the actual boat that is being built in the hangar. It enables the different teams to ‘speak the same language’ using the most up-to-date version of the design, in phase with what is happening in the workshop.

01:21 – 01:41

Antoine Gautier:

Thanks to the cloud, we’re able to connect from anywhere. It allows us to access all the plans and the 3D model of the boat. And it’s typically something we’re likely to do when we’re at sea, in the event of damage, we can read the plans and try to understand what happened in detail. Thanks to Dassault Systèmes, we make the link between the virtual and real.

01:42 – 02:08

Thomas Normand:

We’re very motivated to work on performance improvement, to ensure that these boats can win races and to be able to allow the skippers to deliver messages. And also the R&D and innovation that we develop in our design offices can serve a larger cause. Our business is the sea. So we’re also responsible for reducing our carbon footprint on the oceans.

02:09 – 02:34

François Gabart:

To do this, we decided to implement a sustainable innovation lab at MerConcept. We can make technology transfers from ocean racing to yachting, to the transport of people and goods, aiming for the lowest possible impact, and move towards sustainable mobility on the oceans.

02:35 – 02:50

Thomas Normand:

That's really what we're looking for today: To win races and make sure we can do it in a meaningful way.

Focus on MerConcept

Created in 2006 by François Gabart, MerConcept supports the creation and development of sporting and innovative projects and specializes in engineering, technical studies and boat building. From its base in the harbor of Concarneau in southern Brittany, France, MerConcept’s team is in the beating heart of a dynamic cutting-edge marine economy. Resolutely focused on excellence and driven by a common ambition: to imagine and develop innovative concepts and to create bridges to the maritime world. MerConcept is a purpose-driven company committed to creative and sustainable ocean racing, whose striking innovations are benchmarks for the maritime world.

For more information: www.merconcept.com

Focus on CT Mer Forte

CT Mer Forte is a naval design and architecture office created by Michel Desjoyeaux, one of the most successful sailors globally. Driven by a culture of performance and innovation and the values of sharing and passion for the maritime world, CT Mer Forte has a reputation for success and an ability to innovate. It has a strong collaboration with Dassault Systèmes and is an exclusive distributor and integrator in France for Dassault Systèmes solutions in the marine and offshore sector. Through this partnership and its expertise, CT Mer Forte brings the 3DEXPERIENCE platform and its cloud-based industry solutions within reach of all maritime professionals.