MASCHIO GASPARDO

The Italian manufacturer uses the 3DEXPERIENCE platform from Dassault Systèmes to improve governance from engineering to manufacturing to support.

Meeting the world's food needs

As the earth’s population rises, the land that is cultivated to sustain life remains the same. Yet farmers constantly need to increase output to meet growing demand. Through better farming techniques, they gain in agricultural productivity while preserving precious resources for generations to come. Providing sustainable and efficient farming solutions is an objective of Italian agricultural equipment manufacturer Maschio Gaspardo thanks to its proactive approach to development and innovation.

“When my father founded this company in 1964, his objective was to provide mechanical solutions to help farmers do their jobs,” Mirco Maschio, president at Maschio Gaspardo, said. “Today, however, demand for customized equipment and services is increasing because local farming needs vary—size of land or soil composition are not the same in every country. Moreover, people are more attentive to their health and the environment; demand for organic food and sustainable farming methods have changed the way the land is cultivated. Our customers expect us to provide them with precision farming solutions by way of innovative equipment that we deliver fast without compromising on quality. To meet these challenges, we need to transform our business and improve collaboration among design, sourcing, production and service teams,” Maschio said.

Maschio Gaspardo has a global presence with subsidiaries and sales distribution centers in Europe and Asia, in addition to its main offices in Italy. Successful expansion was possible thanks to a winning combination of business vision and technology. Nevertheless, the intellectual property is Italian, and each site has its own design resources to fine-tune products to respond to local market requirements, available supplies and to local standards.

In recent years, Maschio Gaspardo has experienced doubledigit growth, mainly abroad. “We have expanded into foreign markets by opening two sites in China and India,” Massimo Crozzoli, chief information officer at Maschio Gaspardo, said. “As a result, we have decentralized technical centers of excellence. These centers have remote access to our Italian headquarters, which maintain full control of all design operations.”

With the 3DEXPERIENCE platform we have the technology to produce farming equipment that satisfies imperatives including agricultural efficiency, soil protection and reduced greenhouse gases.

Early 3D adopters

“In the early nineties, we were one of the first companies in Italy to choose 3D as the common language for our organization,” Crozzoli recalled. “Our ultimate goal was to integrate our technical department with the rest of the company. From the very beginning, we used Dassault Systèmes CATIA® design application for our mechanical design needs. Now we have entered the second stage in our evolution in which our decentralized offices also develop real projects with the benefit of the headquarter know how, focusing on local needs,” he continued. “To achieve this, we needed to harmonize our IT landscape with a single platform to manage end-to end development from design to manufacturing,” he said. “We, therefore, adopted the 3DEXPERIENCE® platform to enhance our collaborative capabilities between our different sites, which will allow us to rapidly develop and deliver tailored solutions to market,” he said.

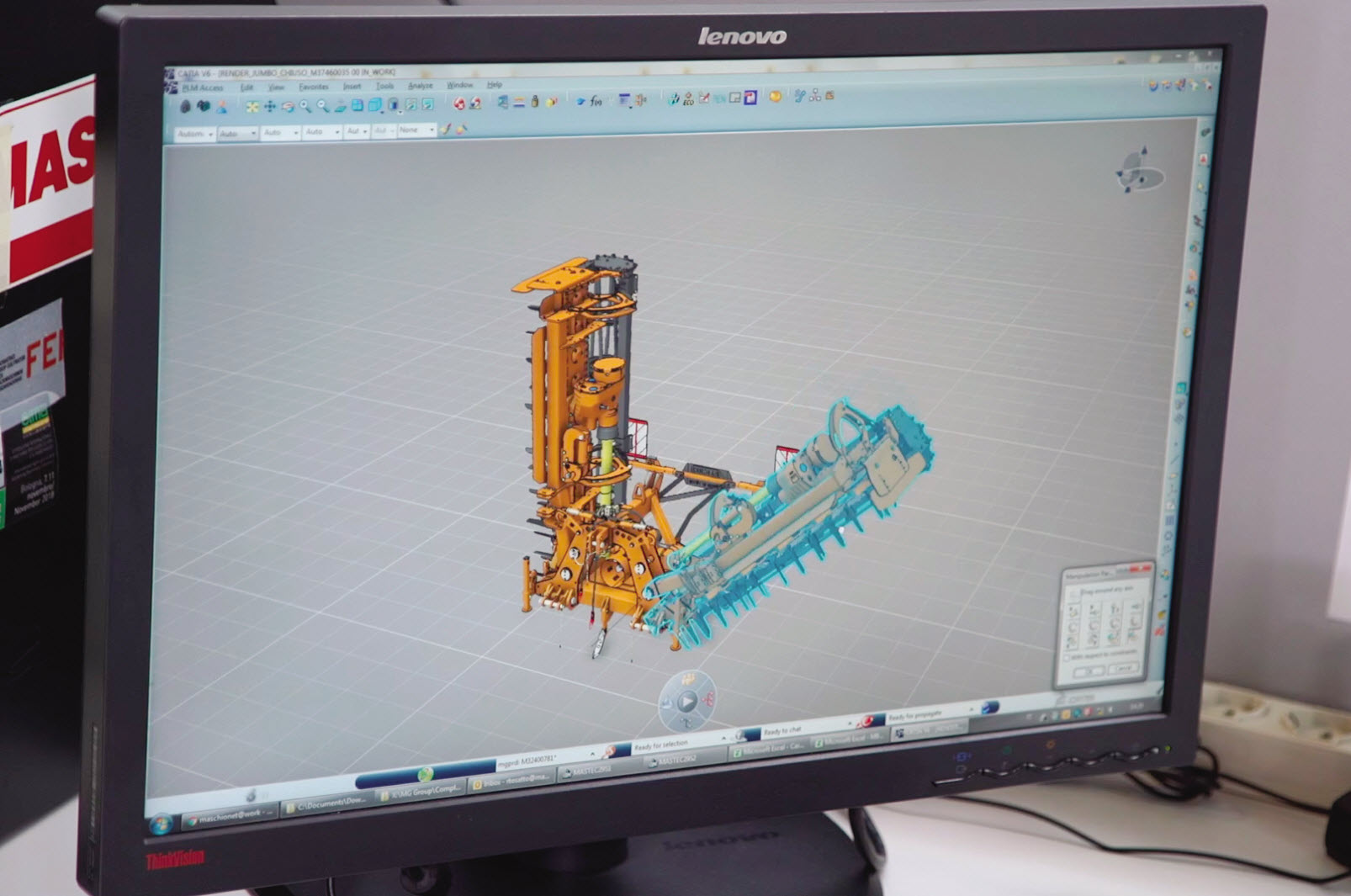

When CATIA was initially deployed throughout the entire group, the benefits were immediate. “We noticed right away that it took less time to build a model,” Crozzoli said. “CATIA is a highly visual and intuitive application that enables us to forego physical prototypes and is easy to learn. Now, with the 3DEXPERIENCE platform, all work can be shared; one engineer designs the seeding elements, another the transmission system, and a different one the various components. An engineer in Italy can work in parallel with one in Romania. We hear so much about collaboration. With the 3DEXPERIENCE platform, collaboration really works,” Crozzoli said.

To manage end-to end development from design to manufacturing between our different sites, we adopted the 3DEXPERIENCE platform, which will allow us to rapidly develop and deliver tailored solutions to market.

Bringing teams together

“Working in silos between disciplines is a thing of the past,” Andrea Ruffin, technical director at Maschio Gaspardo, added. “Today it is possible to create a 3D model in Italy and the associated 2D drawings in India almost in real time. We’ve, thus, reduced the time it takes to develop new products. In addition, with the 3DEXPERIENCE platform, we can create a digital twin of a machine thereby drastically reducing waste and costs that are often associated with physical prototypes. Moreover, the modularization capabilities of the platform allow us to develop and deliver customized products faster to market without compromising quality. Thanks to a single data source we are able to use a higher percentage of carryover components. This was difficult before, when technical offices were located in different areas because everyone was working on data that resided in their individual computers. Today the information is centrally managed and available to all stakeholders, which improves our competitiveness and technology leadership with innovative products that rapidly respond to farmers’ evolving needs,” Ruffin said.

“A good example of this is our new high-speed planter, the Chrono, which doubles a farmer’s productivity by increasing the accuracy of seed delivery and spacing, which makes the planting operation easier than ever,” Ruffin added.

Multidisciplinary data management

The equipment manufactured by Maschio Gaspardo can be very complex because it includes mechanical, electrical, hydraulic and pneumatic parts, sheet metal, cabling, automation mechanisms, and load-bearing frames that require structural analysis. Some 3D models have up to 5,000 parts. Combining mechanical design with product lifecycle management capabilities thanks to ENOVIA®, according to Massimo Crozzoli, was a “momentous change for the group”.

“ENOVIA keeps track of all modifications and versions, maintains a well-ordered repository of a huge quantity of files, streamlines information search and, as a result, minimizes redundancies and the risk of having to redesign existing parts. This is strategic for us since we have a complete range of products and a huge number of components to manage. We can maximize design reuse and benefit from our intellectual property,” Crozzoli said.

Management at Maschio Gaspardo immediately appreciated the benefits of the platform. “We have reduced airline travel by 60%,” Crozzoli said. “Product managers and especially our chief technical officer can interact directly with Indian mechanical designers without leaving the office in Italy. We can easily estimate the benefits in terms of operating efficiency and cost savings now that we’ve deployed the 3DEXPERIENCE platform at all our sites in India, China, Romania, in addition to our five sites in Italy.”

“A pilot project we ran in India proved that designers, assisting remotely, were able to acquire specific know-how very quickly,” Crozzoli said. “They were up and running on the new platform in just three days. With this approach, any R&D engineer abroad can be virtually supported by the central R&D department in Italy, developing skills and expertise very quickly.”

With its centralized approach, the 3DEXPERIENCE platform provides Maschio Gaspardo with a unique and worldwide data source for product creation and change throughout the complete product life cycle. “We now have a single repository in Italy, from which all remote offices obtain information,” Crozzoli said. ”It runs on the same infrastructure we already had, with no impact on the efficiency of our other applications.”

Consistent experience

“We attribute our overall success, in part, to the amazing support we received from Dassault Systèmes and its business partner Iperelle,” Crozzoli said. “First of all, Iperelle helped us identify the applications of the platform best suited to our business. They deployed best practices to increase our productivity with the system and provided training as well as day-to-day support when necessary. To ensure our design needs are addressed by the software, Dassault Systèmes worked on site with us and installed a sort of laboratory on our premises, proving their determination to work with an industry that presents interesting opportunities and potential.”

“The feedback from our engineers is positive,” Ruffin said. “Through better collaboration they are able to share their experiences, which invariably leads to an increase in skills and productivity. Moreover, there is better synergy between engineers working on different sites and more precise control of our product development processes. All these benefits help accelerate new product development.”

When taking long walks or hiking, Mirco Maschio often thinks about the land and how to help farmers do their jobs more efficiently. “I’m constantly thinking about the soil,” he said. “Everyone needs to take care of our planet and at Maschio Gaspardo, we are keen on helping farmers not only to optimize their harvests but to provide them with sustainable solutions that reduce greenhouse gases and protect the soil from degradation. Thanks to the 3DEXPERIENCE platform, we have the technology to satisfy all these imperatives because every stakeholder can participate in making our equipment the best it can be.”

Our engineers’ feedback is positive. They can better collaborate and share their experiences. This synergy invariably leads to an increase in skills and productivity, which is a sure way to accelerate new product innovation.

Focus on Maschio Gaspardo

Italian manufacturer of agricultural machinery.

Products: Rotary tillers, power harrows, precision planters, cereal seed drills, combined seed drills, minimum tillage equipment, mulchers, sprayers, mowers, mist blowers, round balers, square balers, tedders, swathers and wrappers. Maschio Gaspardo has a full range of products that cover all the agronomic lifecycle.

Revenue: 325 million EUR (2017)

Employees: 2,200

Headquarter: Campodarsego, Italy

For more information www.maschio.com

Focus on Iperelle

Iperelle was founded in 2002 and since then, the company has further developed its PLM expertise, supporting customers of all sizes operating in different fields ranging from mechanics, design and construction of molds, consumer goods, technological equipment, aerospace, transportation and planning and design services. It delivers end-to-end support from conception, design and simulation of a product to workshop preparation, technical documentation and management of its complete lifecycle. Iperelle is Dassault Systèmes’ premier partnerin Italy delivering industry solutions based on the 3DEXPERIENCE® platform and its ENOVIA® CATIA® SIMULIA® and DELMIA® applications as well as educational certification.

For more information: www.iperelle.it