JAKSCHE Technology

To meet its customers’ requirements and ensure on-time delivery, leading European manufacturer of innovative plastics JAKSCHE uses the 3DEXPERIENCE platform to accelerate product development and optimize production, while achieving full traceability across the product lifecycle.

Future-proofing plastic innovation

Thermoset plastic components manufacturer JAKSCHE Technology is all too aware of the environmental impact of the core material used in its products. Rather than shying away from the issue, the Bosnian company has committed to becoming one of the most sustainable companies in its field and is actively engaged in the production of ecological, economic and recyclable plastic solutions in a low-carbon, circular economy era.

With 50 years’ experience in making plastic components, JAKSCHE has become a major partner in Europe for leading companies across the construction, automotive and industrial sectors. The company develops and manufactures tools and heavy-duty fiber-reinforced plastic parts used in some of the most demanding settings like water tanks and machine housing, roof shells and vehicle panels. Firmly focused on tradition and innovation, JAKSCHE is committed to delivering the highest quality products that meets both its customers’ and society’s needs.

We appreciated that the 3DEXPERIENCE platform would support us to create a centralized data model and, in future, will enable us to explore the potential of virtual twins.

“Our inventive spirit enriches our products and spurs us on,” said Heidrun Andre, managing director of JAKSCHE. “Our long-term goal is to focus more on exploring the use of natural fibers, biopolymers and recycled materials. For example, we’re a partner in an Austrian bio-based demonstration project to produce a 100% bio-based thermoset using a linseed oil epoxy resin and natural fibers. We’re also focused on optimizing production and have invested significantly in digitalizing our processes.”

Today, the 3DEXPERIENCE platform sits at the heart of JAKSCHE’s digital strategy, helping the company to not only pursue its sustainability objectives but also facilitate enhanced collaboration and optimized product development.

“We want to forge ahead with making innovative products and we needed a powerful, industry leading platform on which to grow our business,” Andre said. “It was critical that we invested in technology that would bring our product development processes together and the 3DEXPERIENCE platform delivers that centralized environment.”

Bringing all departments onto one platform

One of the key objectives of JAKSCHE’s digital strategy was to break down the siloes between company departments.

“Before we started using the platform, communication among R&D, procurement and production was ineffective,” said Miroslav Stolić, chief operating officer at JAKSCHE. “We also had issues monitoring documentation and validating CAD data in each project.”

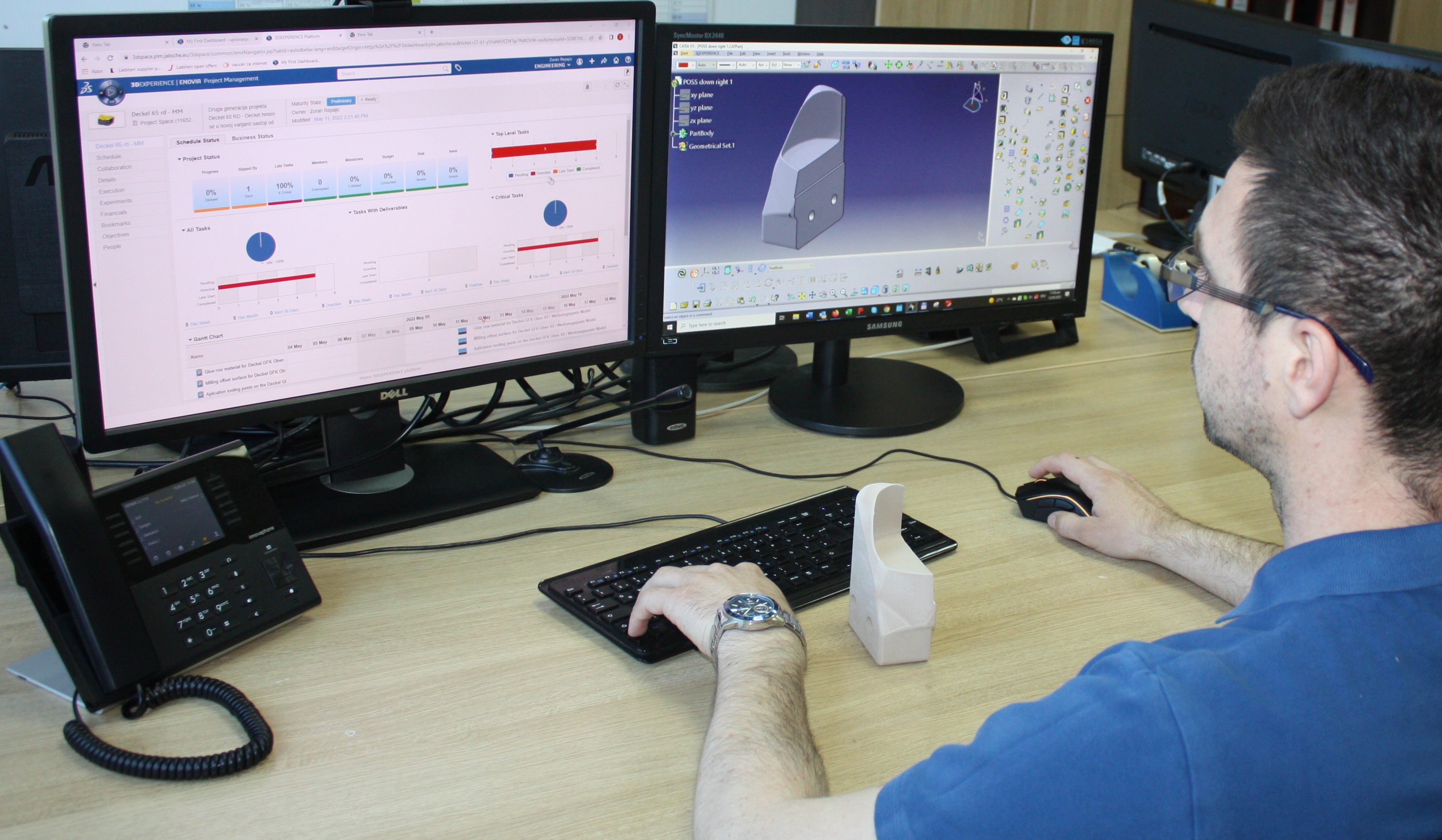

JAKSCHE worked with Dassault Systèmes business partner CADCAM Solutions to find the answer and opted for the 3DEXPERIENCE platform with CATIA for design, ENOVIA for collaborative innovation and project management, and DELMIA for production planning.

“We were already working with CATIA V5 and wanted to ensure data compatibility between our processes and applications, so implementing the 3DEXPERIENCE platform was the logical decision to avoid any compatibility issues,” Andre said. “We also appreciated that the platform would support us to create a centralized data model and, in future, will enable us to explore the potential of virtual twins.”

CADCAM Solutions guided JAKSCHE throughout the decision-making and implementation stages.

“They became a member of the company’s family,” Stolić said. “Their competence and experience helped solve any issues we encountered. We were really impressed by their communication, transparency and professionalism.”

JAKSCHE first prioritized the departments that had the greatest need for the new digital approach on the 3DEXPERIENCE platform, including R&D and procurement.

“We have already noticed a big difference in how these teams work together,” Stolić said. “They’re communicating better, both among themselves and with customers, as the 3DEXPERIENCE platform enables them to quickly access the information they need in one place.”

We have undreamed-of opportunities for flawless design, and production limits can be taken into account at an early design stage.

Getting complex designs right the first time

As customer requirements grow, so do the demands on JAKSCHE’s designers as geometries and contours of the large exterior panels they create become increasingly complex.

“If you look at a caravan, the exterior panels look fairly standard without many shapes and edges. But that’s not the case,” Andre said. “One model’s exterior can have more than five different suppliers and strict tolerances must be met. If they aren’t, mounting and assembly can be hugely challenging. We must get the right information from both our customers and fellow suppliers to deliver precision designs.”

Thanks to CATIA’s advanced modeling capabilities, JAKSCHE is able to get designs right the first time.

“CATIA is the best app in the field of surface modeling, surface tangential control and negative angle control, enabling us to design and build parts and tools adapted to our production process,” Stolić said. “In our industry, the most important step is to recognize and identify negative angles on products. Based on this information, we construct the required tools. If we get it right before the construction phase, we reduce the number of physical prototypes required.”

Seamless integration between CATIA legacy data and the 3DEXPERIENCE platform also enables JAKSCHE to consider all aspects of the entire product development lifecycle from the beginning.

“We have undreamed-of opportunities for flawless design, and production limits can be taken into account at an early design stage,” Stolić said. “With ENOVIA, we can now track all changes during design and share information with all project stakeholders. The platform enables us to monitor the entire project lifecycle. When we change the CAD model, all affected components are automatically updated, and the procurement department receives information about the changes at the time the new model is approved.”

Using ENOVIA for project management, the company is now establishing efficient, reliable and repeatable processes involving the right people at the right time to deliver projects on time and within budget.

“ENOVIA’s simplicity and transparency means that every component is managed centrally. So even if multiple departments make changes and corrections, we can see that feedback in one place,” Stolić said. “Simplified task management and the ability to reuse acquired knowledge on projects is also giving us a competitive advantage and allowing engineers to quickly and easily create offers and answer customer inquiries.”

“We really save on manpower by finding the information we need more easily,” Andre added. “We can create ID numbers for individual parts and quickly find each product. Everything is on the platform.”

Accurate and efficient production planning

JAKSCHE’s production is based on a make-to-order setup, which means that every production run is different.

“We produce fiberglass products for OEMs of large construction machines,” Stolić said. “Our production is mainly manual work like laminating and hand cutting. Until recently, we planned all these processes using spreadsheets and this became complicated to manage. Our planners were losing about two hours per day re-planning and optimizing production, without any possibilities of simulating their plans. We also needed better visibility; production could only see the plan a few hours in advance.”

Using DELMIA, JAKSCHE has transformed the way it manages production planning for the better.

“DELMIA Ortems has helped us achieve dynamic scheduling,” Stolić said. “Now, our planners spend only 30 to 45 minutes replanning and simulating our production for the next few weeks. The visibility of load on our resources and materials has increased, and we can check the schedule in real time to make any corrections well ahead of production.”

JAKSCHE can also identify anomalies and take steps early on to determine if it can accommodate larger production runs.

“We needed to be able to determine whether we could manage an order that exceeded our usual capacity,” Andre said. “It’s been really useful to visualize how we can do these production runs and identify bottlenecks before they become an issue. With DELMIA Ortems, we can do this perfectly.”

Responsive to customer demands

With all information held in one place, JAKSCHE can now cater to its customers’ needs throughout the product development lifecycle and meet their specific industry regulations. In the rail sector, for example, customers typically require a 30-year guarantee and documented workflows corresponding to each part.

“We can now deliver full traceability for our rail customers,” Andre explained. “Without the 3DEXPERIENCE platform, it would be much harder for us to manage this.”

Growing concerns around climate change and ever-scarcer fossil fuel sources drive JAKSCHE to be proactive in its sustainability efforts, and the 3DEXPERIENCE platform will support its new R&D projects.

“We are currently working on a product for the marine industry and we’re using the 3DEXPERIENCE platform to make it happen,” Andre said. “We’ll be able to create a new ID for this particular material, document all its qualities and use cases, and access all the data on the platform. We now have the transparency we need. So, if a customer wants to switch from a plastic part to a flax fiber part for example, we have all the information we need surrounding that particular part. It’s very easy to go into the system and see exactly what’s going on.”

Discover more about the Ready To Make industry solution experience.

Discover more about the Concurrent Equipment Engineering industry solution experience.

Focus on JAKSCHE Technology

JAKSCHE is an Austrian managed industrial company with 50 years of experience in the production of high-quality, fiber-reinforced plastic components and systems made of composites materials. The company develops customized solutions – from development and engineering to the finished assembly, all from one source. JAKSCHE focuses on individual requirements and attaches importance to efficiency and cost, ensuring high flexibility in serial production and guaranteeing on-time delivery.

For more information: www.jaksche.eu/en

Focus on CADCAM Solutions

Based in Bosnia and Herzegovina, CADCAM Solutions is a member of CADCAM Group, a leading product lifecycle management (PLM) solutions provider in south-east Europe. The company provides software and services for mechanical, electrical and electronic systems as well as product development. CADCAM Solutions’ portfolio covers a broad range of software including PLM, CAD and CAM. It brings together industry-leading technology, engineering services and extensive knowledge, developing solutions that meet specific industry and customer challenges.