ISC

Danish consulting and engineering firm ISC leverages the 3DEXPERIENCE platform on cloud to manage its global engineering projects for offshore wind and offshore oil and gas.

Thanks to the 3DEXPERIENCE platform, we can take any design from off the shelf and incorporate it into a new one.

Setting the standard for offshore wind farms

Located in the North Sea, approximately 89 kilometers off the UK’s Yorkshire coast, Hornsea Two is the world’s largest wind farm. With 1.3 gigawatts of power provided, the farm has enough capacity to supply more than 1.4 million homes in the UK with clean electricity, spurring the country’s ongoing transition to renewable energy.

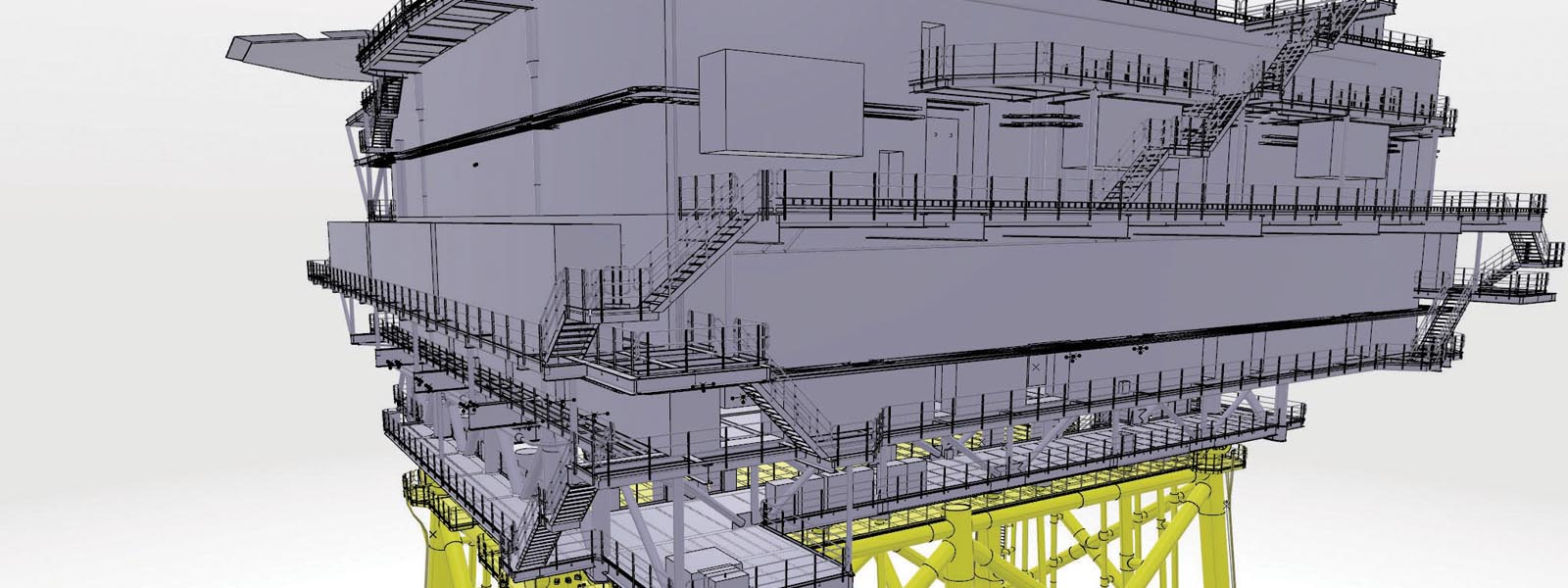

At the center of the farm, installation is underway on the offshore substation (OSS), a 8,000-ton topside installed on a six-legged jacket foundation. The largest built to date, it will collect and convert energy from 165 wind turbines into high voltage electricity, which will travel along long subsea cables and transfer to the National Grid via a reactive compensation station (RCS). Both the OSS and RCS were designed by Danish consulting and engineering firm ISC Consulting Engineers, developer of the first ever offshore substation in 2003 and a leading expert in the sector.

For ISC, Hornsea Two is a clear display of the company’s ability to deliver the entire range of tasks associated with substation design – all honed from its extensive knowledge of offshore oil and gas facilities.

“In the 2000s, we began to see signs of the offshore wind business taking off and were ideally positioned to establish ourselves in this sector,” said Anders Thomsen, president and CEO of ISC. “We have now designed more than 50% of offshore wind substations globally and our original design for the first substation forms the basis for almost all offshore wind farm substations built today.”

As ISC’s business has grown, so too have its customers’ requirements and its own IT needs. A long-term CATIA user, the company needed a platform to centrally store its extensive project portfolio and design catalog and deliver increasingly sophisticated design functionality.

“Today’s substations may share the same core design, but they are much bigger, and we’re now focused on making them as light and as easy as possible to install,” Anders Thomsen said. “History has shown us that every time a customer wants to standardize the substation design, each one ends up being unique. There is always something different. It means that our back catalog of designs is extensive, and thanks to the 3DEXPERIENCE® platform, we can take any one from off the shelf and incorporate it into a new design. We don’t have to reinvent the wheel every time we start a new project.”

Outsourcing to an industry IT leader

ISC’s shift to the 3DEXPERIENCE platform was driven by its desire to centralize all its data and future-proof its business with modern technology. By opting for a cloud implementation, it was an ideal opportunity for the company to outsource some of its IT.

“The cloud was slowly coming to our industry, and we needed an environment we could rely on,” said Christian Barlach, R&D manager at ISC. “It made perfect sense to us that we shouldn’t spend time on setup and maintenance. Dassault Systèmes has taken a lot of hassle away from us.”

Now, ISC’s team members can access new functionality and the data they need themselves using ENOVIA on the 3DEXPERIENCE platform.

“Our users don’t have to go to IT to write and check things or access data,” Barlach said. “Everything is now much more open and natural, allowing us to focus on our key tasks.”

ISC worked with long-term technology partner IPES to make the 3DEXPERIENCE platform work for its business.

“We have a long relationship with IPES going back many years,” Barlach said. “They have been instrumental in our migration and have helped us get to grips with the platform’s rich functionality. They are on the same page as us and have recently come up with a more user-friendly way of reporting issues and queries using the Dassault Systèmes community platform. It gives us full transparency.”

Mastering legacy data

Today, ISC can retrieve over 30 years’ worth of design work via the 3DEXPERIENCE platform.

“Now, we have all the data in one place, and it is much easier to find exactly what we need and share it in an appropriate way,” Barlach said. “Moving away from a file-based structure, we can adopt a creative thinking approach. If you can master your data, you can master your design.”

With all projects organized on the platform, ISC’s engineers can quickly pull together the information they need.

“In a very safe way, you can pick and choose individual assemblies and put them together very rapidly without disturbing the former project,” Barlach said.

ISC uses ENOVIA POWER’BY to connect some of its legacy CAD data to the 3DEXPERIENCE platform, meaning it didn’t have to migrate all of its data to keep seamlessly accessing and using it.

“We have a lot of knowledge data in former catalogs and for us it was going to be more efficient to keep some of that within CATIA V5,” Barlach said.

Using the POWER’BY capability, ISC also has the flexibility to work with other third-party design files and programs used by its partners across the value chain.

“If we have a partner that has a preferred design tool, we can integrate the files ourselves or they can do it with POWER’BY,” Barlach said. “We don’t have to impose solutions on them, and it means we can collaborate with ease.”

If you can master your data, you can master your design.

Solving a multidisciplinary puzzle in 3D

Thomsen describes the development of a substation as a very complex puzzle.

“Getting the right layout so we achieve the lowest volume and weight for the substation platform while optimizing the cabling and structural bearing system – there are a lot of things to consider,” he said. “Putting together all these elements is one big puzzle. We must factor everything into the design, including transportation and installation. For example, the structure is welded to the transportation vessel and must be designed to withstand movement in the sea crossing. That’s where our experience and back catalog of projects on the 3DEXPERIENCE platform comes into play.”

Being able to visualize these design challenges in 3D helps ISC to come up with new solutions.

“The cable pulling arrangement is very complex but using the 3DEXPERIENCE platform we can see what’s possible and solve problems in different ways,” said Erekle Tsakadze, 3DEXPERIENCE platform and CATIA administrator at ISC. “The cables can be eight inches in diameter, so they’re more like a rigid pipe, and you have to place different shackles and find the proper geometric solution for the placement of the cable to optimize the pulling arrangement. We combine all the 3D data and use the parametric approach to find the ideal solution. It wouldn’t be possible to solve this in a 2D environment.”

Designing in context

With all data managed centrally in ENOVIA, ISC can bring together multiple disciplines and stakeholders in one place to solve design challenges faster.

“Concurrent access was a challenge before, but we’re always designing in context of everybody and we needed a platform that could support all disciplines,” Tsakadze said. “Our approach is now far more collaborative. With the 3DEXPERIENCE platform on cloud, it is possible to bring all stakeholders into the same digital environment during the design reviews. We can also fully track all changes.”

This has been key when the company’s main office works remotely on large-scale projects with its office branches.

“We are all connected through the 3DEXPERIENCE environment, which makes it possible to work on the same job,” Barlach said. “For example, on a recent substation project, we were able to work together like we were all sat in the same office. Our remote colleagues can view all the data they need and access it from the web.”

Our approach is now far more collaborative. We can bring all stakeholders into the same digital environment.

Set up for the next generation

While the 3DEXPERIENCE platform has changed some of the ways ISC approaches its work, the company sees it only as a benefit.

“We have a lot of experienced people used to IT in a certain way and sometimes we have to rethink that and adapt to new ways of working,” Barlach said. “They had to become comfortable not seeing their files on a Windows server, for example. But the things they found different, they could see the value in. We’re learning as we go and building our own best practices.”

The company is now able to bring new, inexperienced users onto the platform and get them working productively faster.

Virtual twin vision

As ISC looks ahead, it is exploring the potential of using virtual twin experiences to ensure the seamless transition between all phases of an infrastructure project, including running, maintenance, and end of life of the asset.

“Creating a virtual twin is something we’ve always been hoping for,” Barlach said. “We’ll need everyone in the supply chain to understand that it makes good sense to spend more time and money on the design upfront so it’s complete and leaves no decisions to be made during fabrication. As the industry moves towards a turnkey construction contracts (EPC) approach, I can see the need for this more precise digital representation to carry out operations more efficiently. We want to evolve the industry using the platform.”

ISC has no doubt that Dassault Systèmes and IPES are the best partners in the industry to work with and bring this vision to life.

“When we first began using CATIA in the early days, it fulfilled everything we were looking for,” Barlach said. “Our competition was always typically using something else, but we didn’t find a compelling reason for change. In the end, it turns out we selected the best vendor that has the strongest position today. I feel certain that we’re in the right position to fulfill our vision with the 3DEXPERIENCE platform.”

00:00 – 00:14

Christian Barlach, R&D Manager, ISC:

The world is demanding sustainable energy. To see the wind farm that is sustainable, it's very rewarding to actually see that it matters what you do.

00:20 – 01:03

Andreas Laungaard, V.P. of Renewable Energy and Operations, ISC:

Our offshore substation at Hornsea 2 provides 1300 MegaWatts. It's approximately 1.4 million households worth of electricity. Today, we are doing three times the size and bigger are coming. The offshore substation that is the heart and the brain in the wind farm, collects all the power from the turbines. We transform it to a higher current and send it to shore with cables. The 3DEXPERIENCE platform is playing a central role for us in order to do an efficient design. So making sure that we actually find any issues during the design and not when it goes into construction. With offshore, it's a rough environment. On-time delivery is very important.

01:04 – 01:46

Christian Barlach:

We can bring some of the things that we have seen from the boys room of the gaming industry into our daily work and help people to get a more comprehensive view of our product and come up with better solutions. The understanding of our design is much faster at C-level when they have the opportunity to visit the facility that they put millions of dollars into. With the 3DEXPERIENCE platform, we continue to enrich the data set we have and the industry wants to go from schedule maintenance to more predictable maintenance. So we want to be sure that the digital twin is as close to the physical that is going to be built.

01:47 – 02:27

Erekle Tsakadze, Civil Engineer, ISC:

We also have to meet the new requirements, which is a decreasing size of the substations, in order to reduce overall weight and cost. And that brings us into the new challenge that we have to meet specific requirements from different disciplines like electrical or HVAC or structural or piping support. And we have to remove all clashes between the different disciplines. We combine all elements together in one single model and then we try to optimise. And the 3DEXPERIENCE platform gives us a huge benefit because we can find the best solution in the short time.

02:28 – 02:43

Christian Barlach:

We are trying to bring that knowledge that you have from the discrete manufacturing into our industry, where we really do one of a kind and IPES has helped us a lot on the processes that they are familiar with in other industries.

02:44 – 03:03

Andreas Laungaard:

ISC provided contributions to more than 70% of the offshore market within renewable energy. Today we are looking into a new way of decarbonizing the sector and one of them is a green hydrogen and other is floating wind farms, providing offshore wind for countries that have deeper water than we have seen today.

03:04 – 03:17

Erekle Tsakadze:

We are talking about reducing carbon footprint on a global scale and where we as a whole team, ISC, contributing to the story. And the end of the day, I feel proud to be part of this story.

Focus on ISC

ISC offers independent professional consultancy services within all areas of wind energy, oil and gas, process engineering, construction, and infrastructure in Denmark and internationally. Headquartered in Copenhagen, the company’s main goal is to generate technical and environmentally acceptable solutions that meet the client’s demands and keep up with the evolution and goals of society.

For more information: www.isc.dk

Focus on IPES

IPES sells and implements PLM and 3D software solutions that support and optimize the entire process from idea to implementation, supported by Dassault Systèmes, a software partner since 2006. The company strives to help its customers optimize and automate their development processes and working methods using 3D engineering, paving the way for enhanced innovation and greater profitability.