Hexcel

Hexcel is a world leader in the manufacture of advanced composite materials for commercial aerospace, space and defense, energy generation, transportation and recreation.

DELMIA’s solutions for manufacturing and supply chain support Hexcel's value. ONE HEXCEL: Accountability, Responsibility, and of course, Innovation.

Hexcel's strategy is to be number one in the markets they serve

Hexcel is a global leader in manufacturing advanced composite materials for commercial aerospace, space and defense, energy generation, transportation, and recreation.

Don Morrison, Senior Vice President & Chief Information Officer at Hexcel, emphasizes the company's strategy to be number one in the markets they serve with advanced composite materials. Meeting and exceeding customer expectations is a critical component of their approach, ensuring timely and accurate responses to their customers.

Using DELMIA Quintiq and DELMIA Apriso throughout all Hexcel sites

Daniel Carrick, Supply Chain Manager for Global Fibers, explains that DELMIA Quintiq enables them to load production plans over a two-year horizon into their ERP system. This integration flows requirements down to sister sites within their vertically integrated company. DELMIA Quintiq has consolidated multiple fragmented planning tools into one, allowing for rapid assessment and better decision-making regarding supply chain support.

Hexcel also employs DELMIA Apriso across all their manufacturing sites. Looking ahead, the company plans to expand the functionality delivered to the shop floor through the use of DELMIA Apriso. Random Kiser, Director of IT Manufacturing Systems, highlights the benefits of having a common entry point for all operations personnel worldwide. Supporting a single platform simplifies IT management and ensures data consistency for team analysis.

Having all data in one place and in one format

The significant benefits for Hexcel include product consistency, reduced scrap, increased throughput, and enhanced safety due to less touch time on products. Standardization across factories and digitizing documents into a single system allows business analysts to evaluate performance consistently. Operations teams can track product status and equipment condition in real time, while engineering and quality teams ensure up-to-date documentation. Customers benefit from knowing that products meet the latest specifications, quality levels and delivery deadlines.

One Hexcel: Accountability, Responsibility and Innovation

In conclusion, Hexcel's advanced manufacturing and supply chain solutions not only benefit employees and customers, but also reinforce the company's commitment to innovation and operational excellence. By leveraging cutting-edge technology, Hexcel continues to lead in their industry, delivering superior products and services to its customers.

Challenge

Hexcel’s mission is to create value for their customers through the delivery of exceptional advanced composite materials that meet or exceed expectations for quality, on-time delivery and performance.

Solution

Hexcel utilizes DELMIA Quintiq for advanced planning, ensuring precise inventory management to optimize availability for its customers. Additionally, DELMIA Apriso is leveraged to maintain rigorous product quality standards, emphasizing “right first time, every time” on the shop floor.

Benefits

DELMIA enables Hexcel to rapidly analyze customer demand and utilize the supply chain more effectively to meet customer needs. On the shop floor, it provides detailed process plans, offering step-by-step instructions for workers and allowing data collection throughout the production process. This includes validation of materials used and a digital thread of materials produced; ensuring Hexcel maintains high quality standards and employee safety.

Focus on Hexcel

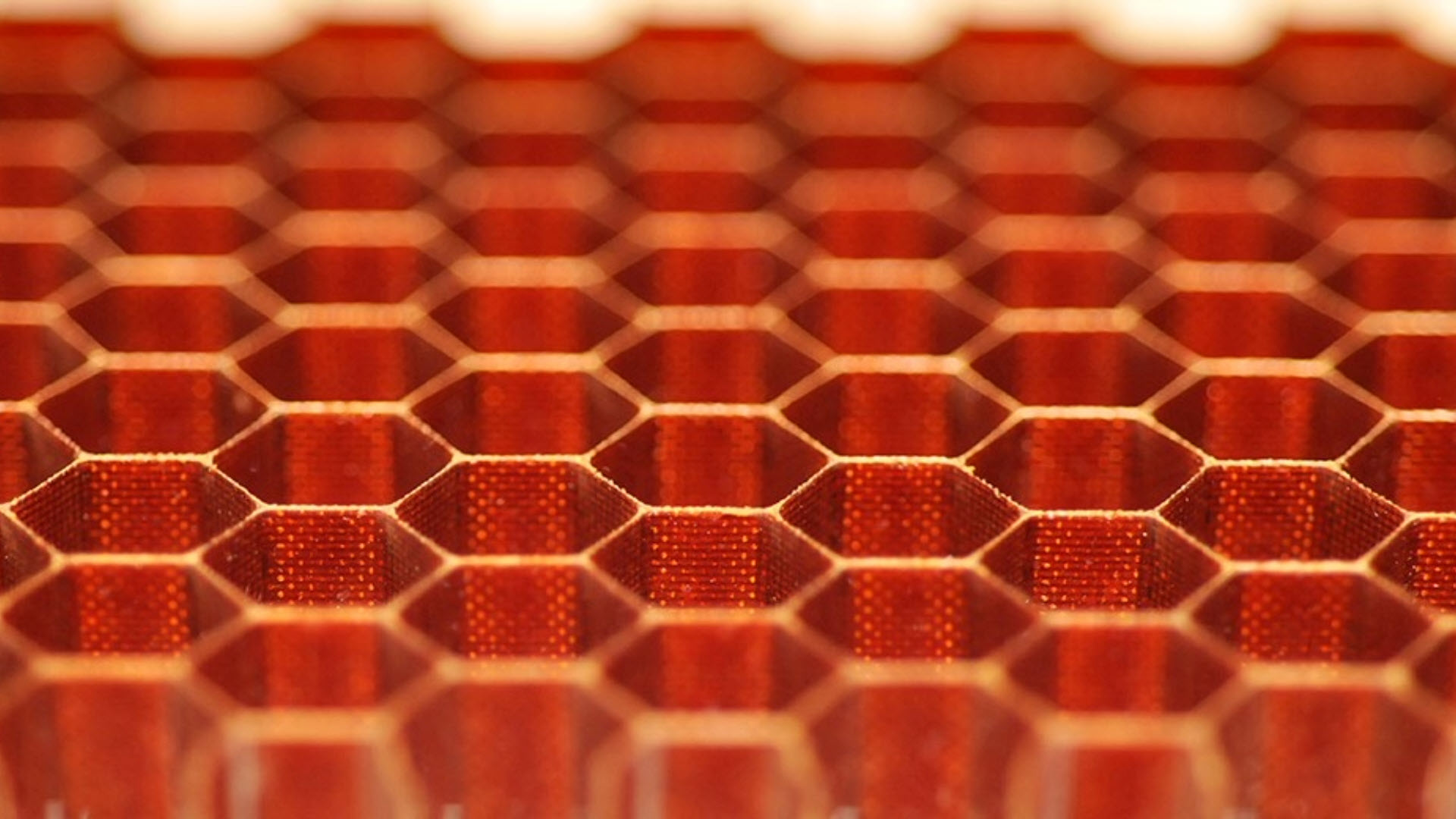

Hexcel Corporation is a global leader in advanced lightweight composites technology. We propel the future of flight, energy generation, transportation, and recreation through excellence in providing innovative high-performance material solutions that are lighter, stronger and tougher, helping to create a better world for us all. Our broad and unrivaled product range includes carbon fiber, specialty reinforcements, prepregs and other fiber-reinforced matrix materials, honeycomb, resins, engineered core and composite structures for use in commercial aerospace, space and defense, and industrial applications.

For more information: Hexcel Corporation.