Harbinger

US-based electric vehicle company Harbinger adopted the 3DEXPERIENCE platform to manage the entire product development cycle of its innovative battery-electric chassis, which is helping to electrify medium-duty trucks. The company benefits from centralized data management and collaborative features.

A Harbinger for medium-duty truck electrification

The electric truck market may still be in its infancy compared to passenger electric vehicles (EVs). Yet, an explosion in demand for last-mile delivery and distribution services is accelerating the need for more energy-efficient and cost-effective medium-duty trucks.

One company driving the transformation of an industry segment it says is “starving for innovation” is Harbinger. The California-based startup is busy developing a pioneering chassis for battery-electric Class 4 to Class 7 vehicles, everything from commercial walk-in delivery vans and box trucks to school buses and motorhomes. Harbinger’s CEO and co-founder John Harris explained that his company is pooling its expertise in EVs, batteries and drivetrains to bring this first-of-its-kind EV platform to market and serve a sector that is ideally suited for electrification yet continues to run on decades-old technology.

“Today, the vast majority of medium-duty trucks do some kind of last-mile delivery, making them an ideal candidate for electrification,” Harris said. “They’re almost always fleet operated, cover the same shorter-range distances, and run on a schedule that’s conducive to charging. Parked in the same place every night, they can be charged slowly and cost effectively. We’re talking about transforming an entire sector without having to change its habits.”

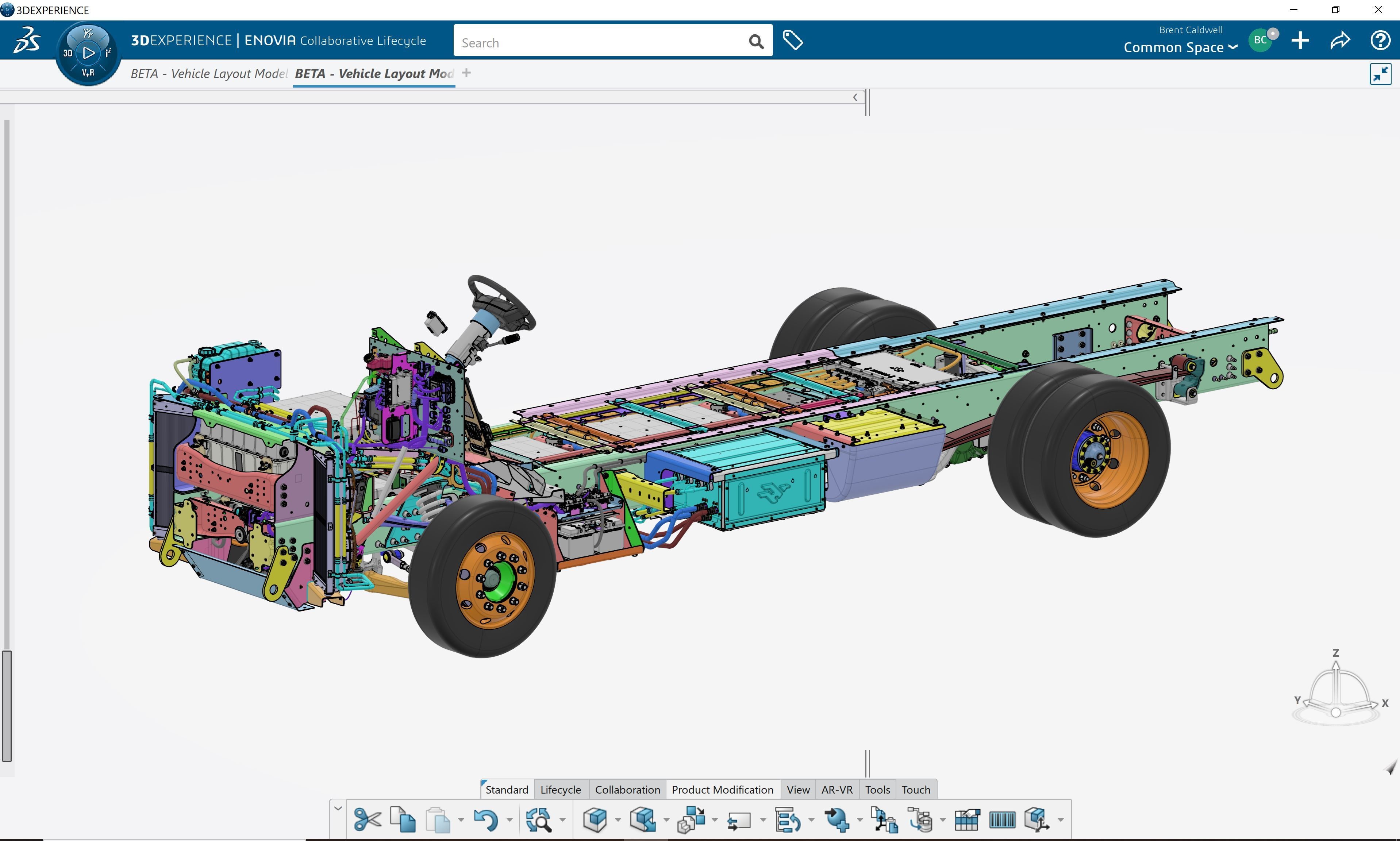

Rather than simply retrofitting existing internal combustion engine vehicles, Harbinger set out to engineer a new medium-duty EV solution from the ground up with a reimagined chassis architecture. Harbinger’s scalable chassis – developed on the 3DEXPERIENCE® platform on the cloud – is designed to improve the driver experience, enhance performance and safety, and reduce running costs. To encourage widespread adoption, the medium-duty EV will be priced to compete with gas and diesel-powered trucks.

Vertically integrated EV keeps costs down

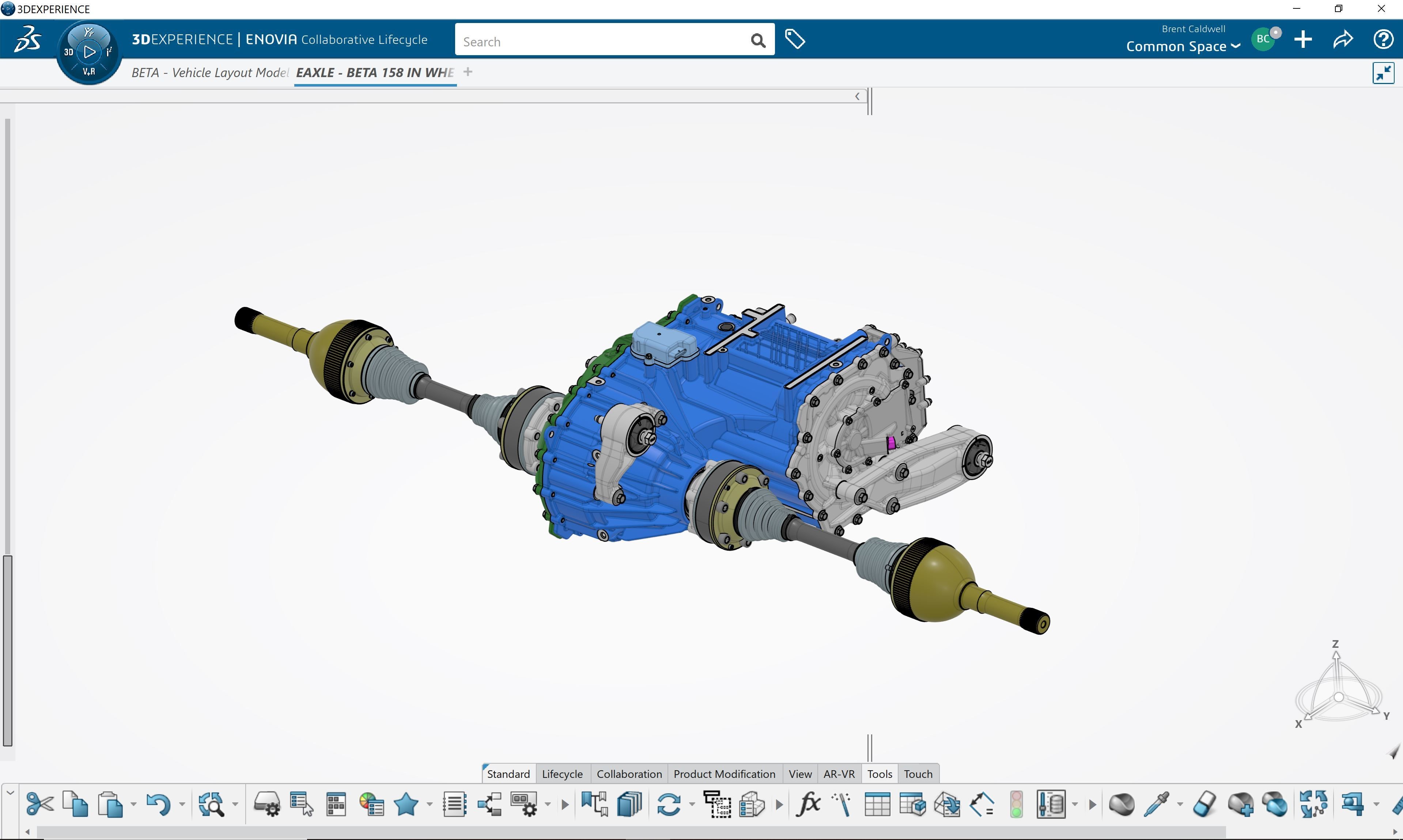

For Harbinger to succeed in making a commercial EV at no cost premium, it’s developing all key components in-house. Building from scratch allowed Harris and his team to rethink their approach of developing a new chassis architecture, including a proprietary eAxle that integrates the motor, inverter and gearbox within a single, replaceable unit.

"Like passenger vehicle manufacturers, we’ve taken a vertically integrated approach to our product development, meaning that we build and integrate everything ourselves, including the chassis, battery system and drive train,” Harris said. “It means we can deliver a cost competitive vehicle without compromising on performance, efficiency or durability.”

Harbinger needed a rich development environment that could seamlessly integrate all disciplines and manage all the data related to every facet of the vehicle throughout its lifecycle. Using the 3DEXPERIENCE platform on the cloud enables Harbinger to involve all stakeholders and team members to access the data and latest communications at any time, on any device, from anywhere.

“When you’re doing something as complicated as building a vehicle from the ground up, it’s essential that we have a very mature, stable and durable PLM platform, which supports us by handling everything from CAD and engineering bill of materials (eBOM) to virtual builds,” Harris said. “It must be able to scale with us as we continue to evolve, and that’s exactly what the 3DEXPERIENCE platform delivers.”

When you’re doing something as complicated as building a vehicle from the ground up, it’s essential that we have a very mature, stable and durable PLM platform [...]. It must be able to scale with us as we continue to evolve, and that’s exactly what the 3DEXPERIENCE platform delivers.

Reliable PLM technology and support

While basic technology solutions may be tempting for startups, Harris advocates investing in a proven industry platform that delivers all the best practice workflows and functionality needed now and in the future.

“It’s important to choose the right platform for your business as you don’t want to change it later on,” he said. “There are many web-based platforms out there with impressive looking demos. However, most fall down when it comes to PLM. When you have to release long-term durable customer-facing engineering, you need robustness.”

For Harbinger, the 3DEXPERIENCE for Startups program provided an accessible and affordable route to taking advantage of the full power of the 3DEXPERIENCE platform on the cloud and all related apps, including CATIA, ENOVIA, SIMULIA and DELMIA. A cloud-based installation was particularly appealing for the fledgling business, which needed immediate and scalable access to the full suite of applications.

“To jump into licenses at full cost is a big bite for a startup,” Harris said. “This way, we can access the platform’s full functionality in a more affordable manner. And, for a venture company like us, the cloud made total sense. We don’t want to be maintaining on-premise servers when we have the option to use the cloud-based platform with all the transparency, security and flexibility that comes with it. I don’t see why you’d use anything else.”

Harbinger’s trusted North American reseller, implementation and training partner Tata Technologies provides ongoing technical support. As a leading product engineering services provider, Tata Technologies possesses the experience and diverse skillset Harbinger needs as its requirements of the 3DEXPERIENCE platform continue to evolve.

“I’ve been working with Tata Technologies for a long time,” Harris said. “They deliver the full scope of support we need and are a true expert in the field. There is way too much attached to the 3DEXPERIENCE platform to buy from someone who doesn’t have that expertise and scale. Their in-house domain experts are familiar with all the platform’s capabilities and help us figure out our digital roadmap. When we start looking into more specialized license packages, we know they can help us make the right decisions.”

A reimagined driving experience

Key design features of Harbinger’s medium-duty trucks include a double wishbone front suspension, which reduces front overhang to improve driver visibility and vehicle manoeuvrability. By tightly integrating the battery powertrain within the chassis frame, Harbinger lowered the step-in height of the truck to below 28 inches – key for a delivery driver getting in and out of the truck, making around 200 stops a day. Everything has been designed and integrated with CATIA on the 3DEXPERIENCE platform.

“Until now, this has been a market where ‘good enough’ is the standard and electrification has been a box-checking exercise,” Harris said. “We took the opportunity to transform the driving experience for the better. The front suspension, for example, is a radical improvement and the difference in handling is incomparable.”

Harbinger’s engineers work in the same development environment, from the chassis, drive train and battery teams to the user interface and packaging groups. ENOVIA, powered by the 3DEXPERIENCE platform, facilitates a unified, collaborative change process that clearly communicates change decisions and tasks to impacted departments.

“We’re moving rapidly through product development,” Harris said. “This year, we’ve been taking our learnings from testing and validation and coordinating change actions across teams simultaneously. We have regular meetings where we look at the vehicle and discuss the implications of moving a chassis or battery element. If we were all working separately in siloed applications, it would be impossible to do anything live. Thanks to the platform, we can see everything and make those informed trade-offs on the spot.”

This transparency and connectivity are crucial as the company progresses to the next stages of development and will need to manage multiple product configurations in production. Here, ENOVIA is key for creating and maintaining a complete, accurate and up-to-date bill of materials.

“As we move from engineering into production, we’re shifting the focus from the eBOM to the manufacturing BOM,” Harris said. “We’ll have different wheelbases and battery packs to integrate, so the BOMs must cover all those variations. That seamless connectivity from engineering to manufacturing helps us work faster in a lean environment with a smaller number of people.”

A benchmark commercial EV built to last

As Harbinger gears up to launch its first commercial EVs to market in 2024, the company is beginning to take advantage of more features in the 3DEXPERIENCE platform, including DELMIA’s digital manufacturing and planning capabilities.

“We’re just starting to bring in elements of the platform that have a more future-looking scope such as DELMIA for build work and mBOM management,” Harris concluded. “It will be invaluable for helping us to figure out what assembly jigs we need and what order to put everything on the vehicle. The 3DEXPERIENCE platform also will support our trucks throughout their operational lifetime – around 20 years, which equates to 450,000 miles. We’re talking about maintenance planning, ergonomic studies and tool path planning. Everything needs to be easy to maintain and replace along the way.”

In the very near future, we can expect to see Harbinger electric trucks doing the rounds in US neighborhoods, transporting goods – and people – in a safe, smart and environmentally friendly manner. This new generation of medium-duty trucks promises to redefine how commercial EVs are made and operated; a harbinger of what’s truly possible if you’re willing to think outside the box.

Discover more about the Efficient Multi-Energy Platform industry solution experience.

Focus on Harbinger

Harbinger is a commercial EV company on a mission to transform an industry starving for innovation. Harbinger’s best-in-class team of EV, battery and drivetrain experts have pooled their deep experience to support the growing demand for medium-duty EVs. Leveraging a foundation of proprietary, in-house developed vehicle technologies designed specifically for commercial vehicles, Harbinger is bringing a first-of-its-kind EV platform to market, priced for zero acquisition premium.

Headquarters: Garden Grove, CA

For more information: https://harbingermotors.com

About TATA Technologies

Tata Technologies casts a wide global footprint, enabling us to help ambitious automotive, aerospace, industrial, and consumer goods manufacturers around the world make better products for their customers.