Executive Insights - Bertrandt

Watch our next Executive Insights episode with Dr. Holger Müller, Vice President Operations at Bertrandt, and Laurence Montanari, Vice President of Transportation & Mobility industry at Dassault Systèmes.

Perspectives from leading enterprise executives in Transport & Mobility

Listen to the lively discussion about how the virtual world will support auto OEMs and its suppliers to develop and test new car functions immediately – without the need for hardware or a test in real world. Simulation and virtually testing real-life scenarios help to evaluate impacts before creating any experience in the real world. Functions, components and entire systems are optimized, shortening development times and saving costs.

Dr. Müller and Montanari share insights on:

- the importance of testing and validating the different what-if scenarios to make sure every system is working according to its design and safety protocols

- the sustainability challenges that carmakers are facing

- the increased amount of sensors in your car and how this increased radiation may affect the human tissue

Video transcript

00:00:10

Laurence Montanari

Hello and welcome to a new episode of Dassault Systèmes Executive Insights. My name is Laurence Montanari and I am the Vice President of Transportation and Mobility industry. Today, I’ve the pleasure of discussing with one of our customers a very interesting topic driving the automotive industry– it’s about bringing vehicles to market with less physical testing.

Now, I would now like to welcome Dr. Holga Müller, Vice President Operations at Bertrandt.

Hi Holger, please introduce yourself and your company.

Dr. Holger Müller , Bertrandt

Hello and thank you for the invitation. I’m Holger Müller, Vice President Operations at Bertrandt.

Bertrandt operates as one of the leading technology partners for the automotive, aerospace and industrial equipment industries.

Our company has been around for almost 50 years and we employ nearly 13,000 people worldwide.

Laurence Montanari

What services do you offer to the automotive sector?

Dr. Holger Müller , Bertrandt

Our services include all steps in the project phases of marketing and conception, product design, development, modeling, tool production, and vehicle construction, including production planning and after sales.

All individual development steps are validated by simulation, prototype building and testing.

00:01:27

Laurence Montanari

Wow, I think your company has a lot of expertise, which is essential for car makers and suppliers. They wouldn’t be able to succeed without you.

From your experience and coming to today’s topic: why is simulation and hardware-free development so important in the automotive industry?

Dr. Holger Müller , Bertrandt

It doesn’t matter whether it’s about electric mobility or highly automated driving or other important topics such as vehicle safety, i.e. personal protection, we are dealing with a high level of complexity in development.

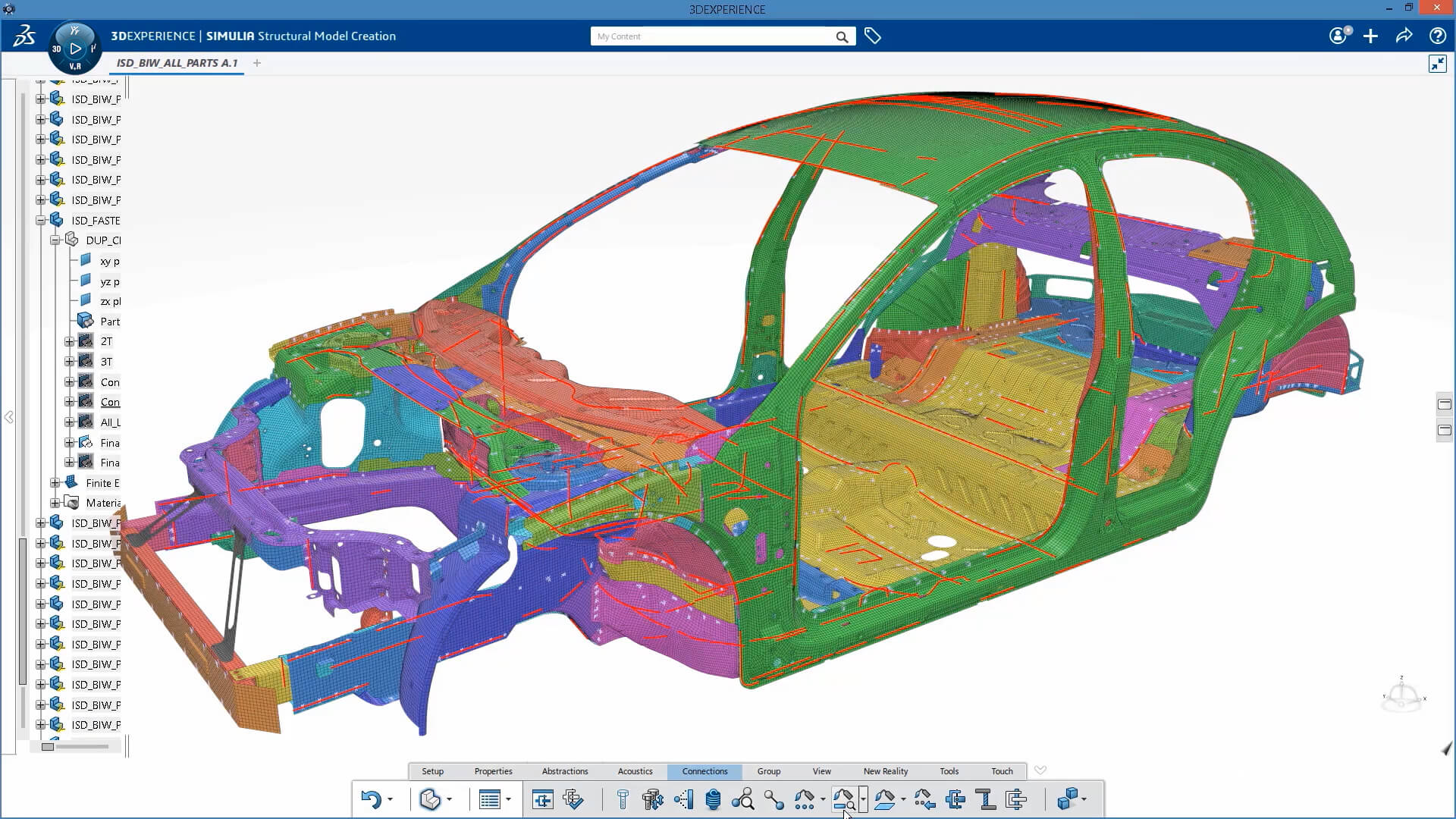

Many components have to interlock correctly and functionally - from the vehicle's hardware to the software. With hardware-less development, we make complexity manageable. We use simulation to test different vehicle functions in a virtual environment. This helps us to better understand the complexity without numerous hardware tests.

Laurence Montanari

Working at an OEM before joining Dassault Systèmes, I know exactly what you’re talking about. So, how does Bertrandt now come into the game and how does Bertrandt support the auto OEMs?

Dr. Holger Müller , Bertrandt

We support our customers with what we call "virtual-controlled development." We simulate reality on the computer.

The ability to simulate real-world scenarios and virtually test them helps OEMs to quickly develop existing and new vehicle functions to a high level of maturity.

This way we ensure that functions, components and entire systems are optimized to shorten development times and save costs.

00:03:03

Laurence Montanari

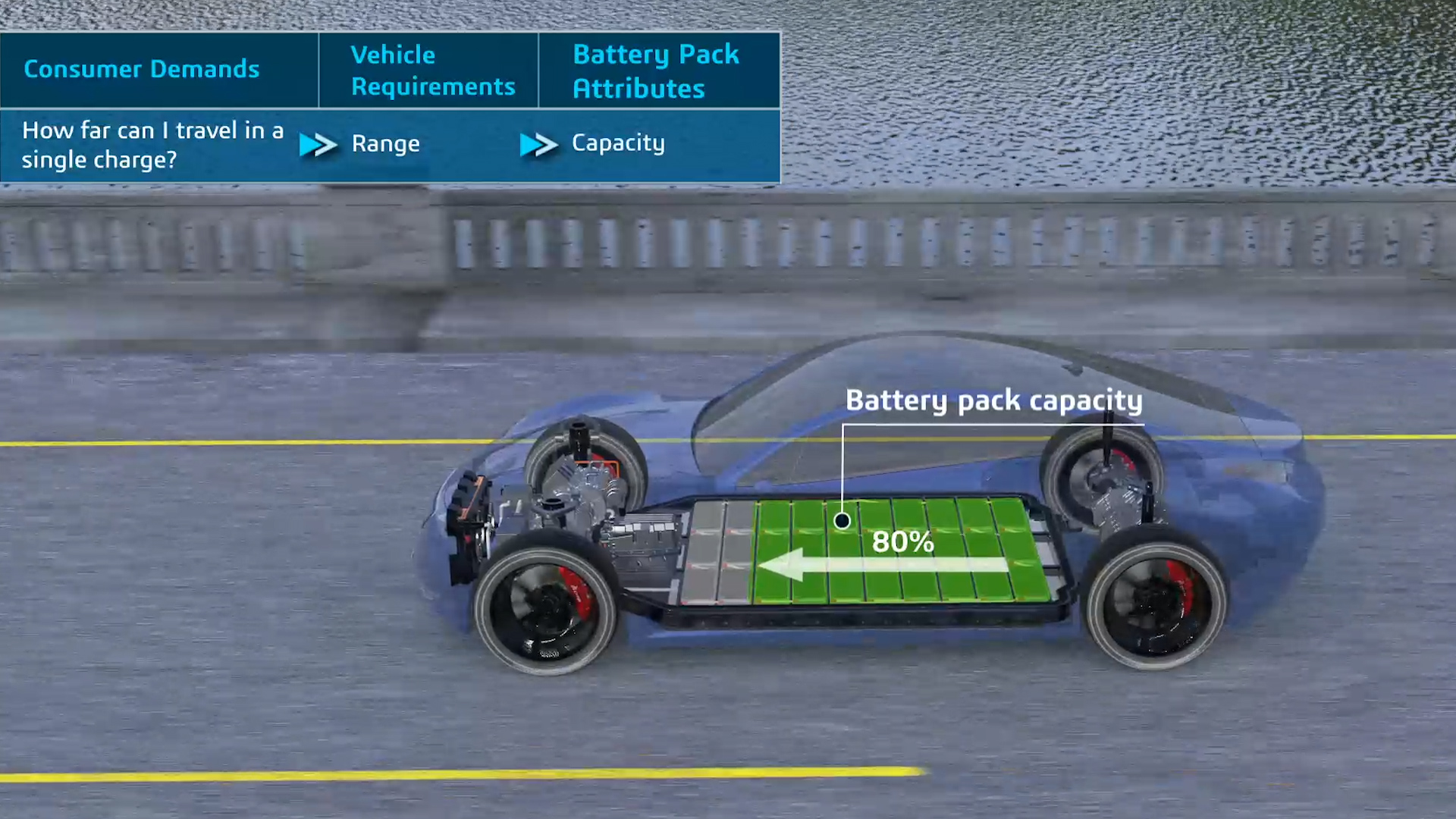

I agree, in the virtual world we can simulate and evaluate impacts before creating any experience in the real world. So let’s go a bit more into detail - you’ve mentioned a few topics where hardware free development pays off – like sustainability. We know that car makers have already cut CO2 emissions by 30% with EVs. We also know that they need to become carbon neutral by 2050. Can you explain how simulation can help to address the sustainability challenges for car makers?

Dr. Holger Müller , Bertrandt

Yes, of course, not only car performance but also sustainability is an important development goal today. There are a number of influencing factors.

For example, all components must become more durable and repairable.

And also weight reduction naturally leads to less energy consumption.

And less weight also means that fewer materials are needed for production, which in return means less waste disposal at the end of a vehicle's life cycle.

And the best thing to consider is how to substitute materials with more sustainable raw materials.

With simulation, we can make an important contribution to each of these aspects.

This allows us at an early stage in the concept development to check whether we achieve the optimum in terms of price and ecological footprint.

And, of course, we do this in such a way that all the necessary safety and comfort-related development goals are met.

00:04:36

Laurence Montanari

Okay, so you just said it – sustainability and fewer raw materials.

How can reducing materials co-exist with more stringent safety requirements? Would you mind sharing some concrete examples?

Dr. Holger Müller, Bertrandt

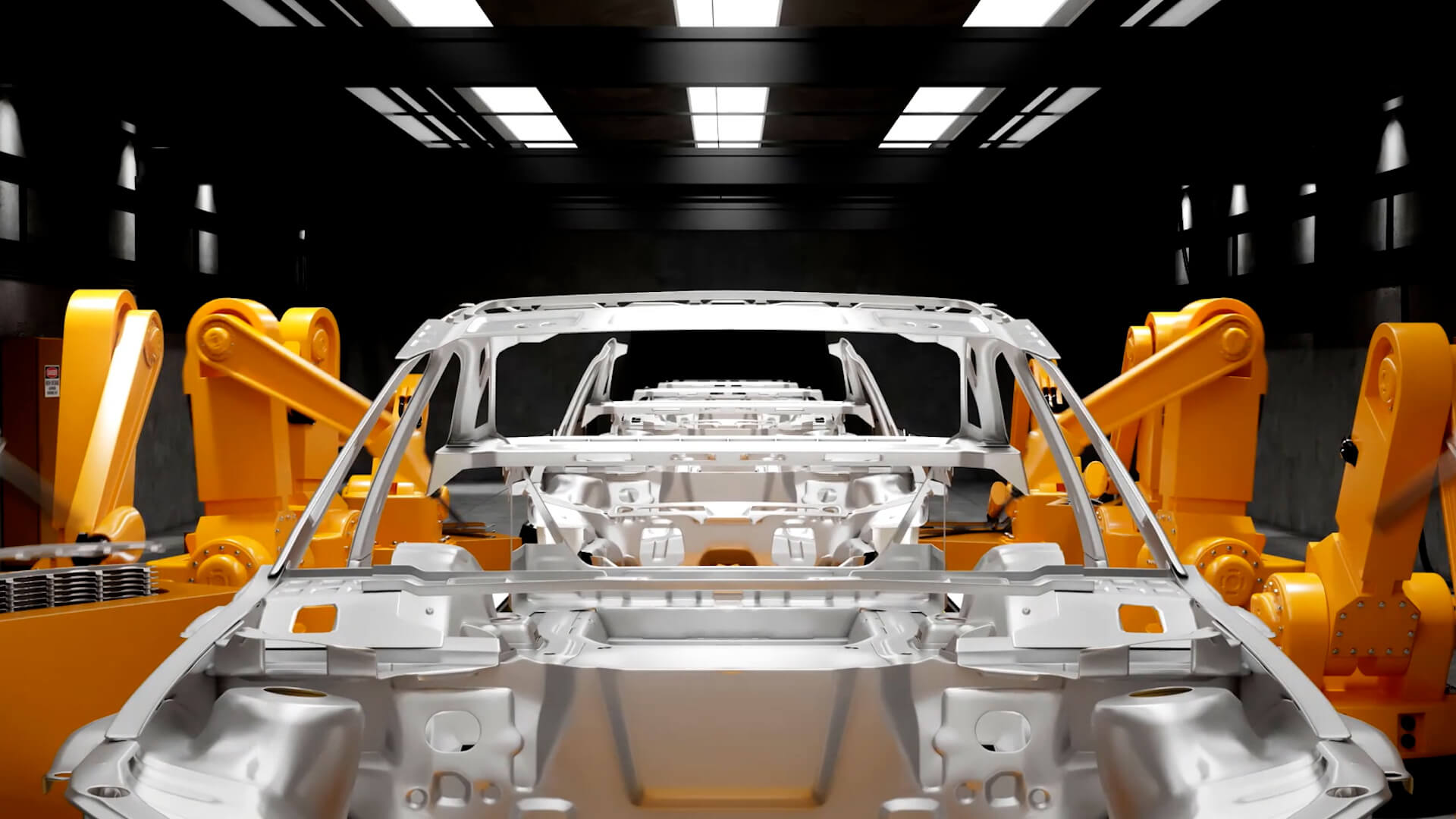

Let's take a normal car accident. Here, we must protect the occupants. To achieve this, the car body should have a large crumple zone to keep the stresses on the occupants low while also minimizing deformations in the survival space.

We solve this conflict of objectives by optimizing the use of high-strength and flexible materials. And to find the optimum compromise in such a constellation, simulation-based development is the right tool for efficient implementation.

00:05:28

Laurence Montanari

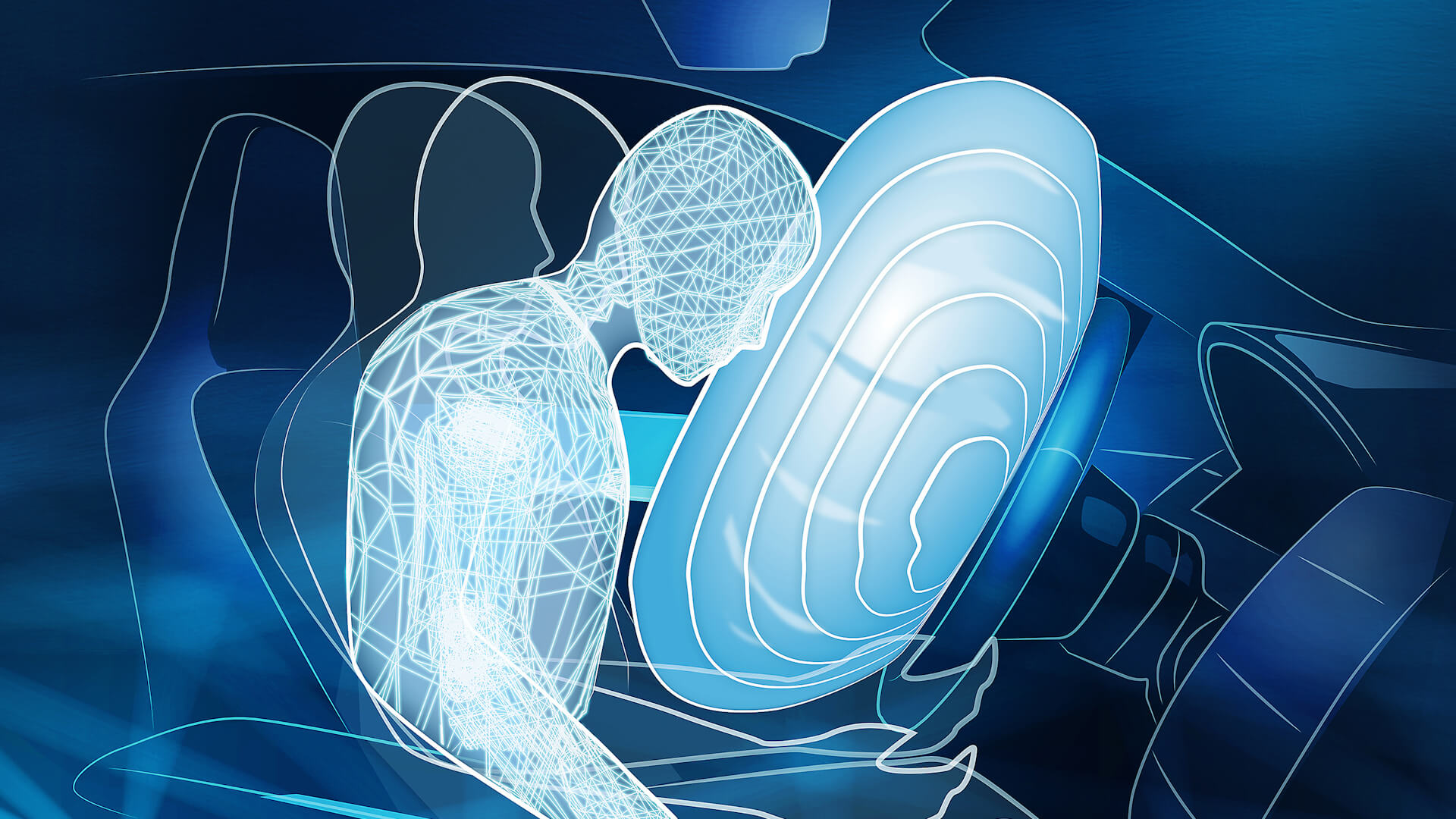

There’s another topic that comes to mind: It’s a matter of electronic systems. They are so important for safety, both active and passive, and also for the comfort of passengers. There are a lot of magnetic waves in a car and not only from parts of the vehicle but also from a smartphone. So, I have one question for you. How do you validate that all these electronic components are working well together?

Dr. Holger Müller , Bertrandt

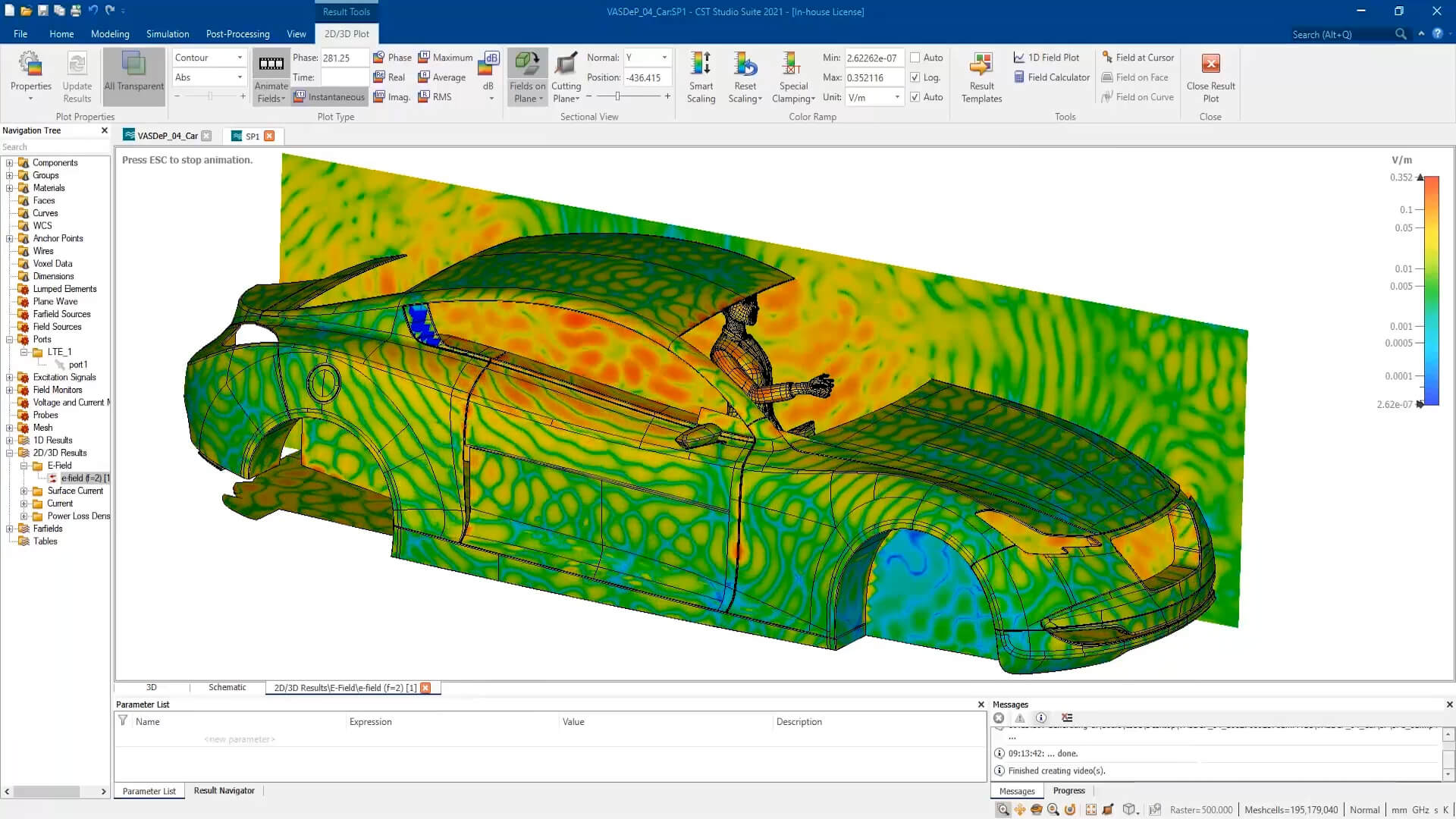

Yes, all of these trends introduce a large number of sensors to detect the interior and surroundings of the vehicle. And this means a huge increase in radio wave emissions.

It is, therefore, important to simulate the effects of this increased radiation on human tissue. However, the vehicle functions themselves and the surrounding infrastructure are also affected or disrupted by the increased emissions.

To look at all the aspects of automated, connected and electric driving, we have developed our HARRI. HARRI is a visionary mobility concept for future automated driving.

Laurence Montanari

Oh yes, HARRI. The best of both worlds – real and virtual. And your company won the German Innovation Award in 2020 with this autonomous vehicle – congratulations!

Dr. Holger Müller , Bertrandt

Thank you, yes, to sum up, I believe that simulation based on robust results with a virtual twin can overcome the constraints of hardware and its bottlenecks.

00:07:07

Laurence Montanari

Right, and our collaborative platform connects the model of new products and services to the value of the experience in the real world. It’s what we call the V+R, virtual and real.

This also facilitates collaboration between departments:

So before we go: What about our collaboration? The collaboration with Dassault Systèmes?

Dr. Holger Müller , Bertrandt

With the 3DEXPERIENCE platform and especially with SIMULIA, Dassault Systèmes provides exactly the right tools that we need to tackle the challenges we discussed.

Thanks to our close partnership, our feedback on the many issues that arise during development allows for continuous improvement of the software tools. This benefits not only us and Dassault Systèmes, but also our customers.

This collaborative partnership at eye level has been going on for many years, and I think both companies can be justifiably proud of it.

Laurence Montanari

Ah, that’s nice to hear. Thanks for sharing insights with us and for being my guest.

Danke sehr, Dankeschön and all the best for you and Bertrandt.

Dr. Holger Müller , Bertrandt

Thank you. All the best to you and Dassault Systèmes as well. Goodbye.

Laurence Montanari

Goodbye.

More about Bertrandt

Bertrandt is an independent and international development service provider with long years of automotive expertise. Through the development performance, Bertrandt accelerates technological progress and makes a relevant contribution to a sustainable future with around 13,000 employees at over 50 sites worldwide.

With cross-industry know-how and a holistic understanding of systems and products, the company creates technological solutions at any stage of the product development process. Bertrandt is focused on hot topics such as digitalization, e-mobility and autonomous systems, mainly for the automotive, aerospace and mechanical engineering sectors, and consistently facilitates the development of tailored solutions in these areas.

Visit Bertrandt website: https://www.bertrandt.com/

Meet Our Speakers

We Help Our Clients Create an Impact

Watch engaging thought leadership discussions with our customers, discover how we are empowering tomorrow's talents, and explore how our leading industry solutions and transformative experiences are supporting our clients.

Discover related content

From connected vehicles to new customer experience, take a look at the future of transportation and mobility industry where sustainable and autonomous technology rule.

Get inspired by our customer stories

Hear from our customers to learn what made Dassault Systèmes the ideal choice for their businesses.