EPFL Racing Team

The Swiss EPFL Racing Team is the first Formula Student organization with its own sustainability department. The team uses the 3DEXPERIENCE platform and its Sustainable Innovation Intelligence solution to assess the environmental impact of its electric formula racing car. Through a comprehensive lifecycle assessment (LCA), they can examine which areas of the vehicle to improve, using this analysis to guide the eco-design of its next-generation racing car.

Each year is a new chance to improve the car. LCA guides us to design a vehicle that is truly sustainable without compromising on performance. Eco-design is a mindset. In less than a year, we put in place a system to perform an LCA and develop a sustainability strategy. If we can do it, then what are you waiting for?

Motorsports races towards a sustainable future

At the École Polytechnique Fédérale de Lausanne (EPFL) research university in Switzerland, a group of students believe that motorsport can be a force for good. They’re on a mission to develop high-performance Formula racing cars that also set an industry benchmark for sustainability.

Just as Formula E and Formula 1 are a testbed for the new technologies needed for a low-carbon future, the EPFL Racing Team is shining the light on how Formula Student can also contribute to a more sustainable world. It’s the first Formula Student organization to have its own sustainability division committed to measuring and reducing the carbon footprint of the team and its cars at every stage of development.

Hugo Fenoli-Rebellato leads the sustainability division. As one of the founding members, he is passionate about tackling global warming and hopes that his team’s efforts will drive responsible innovation in Formula Student and beyond.

“We all share a common passion for motorsport,” he said. “We’re also convinced that no matter the business you are working in, sustainability should always be considered. Most of the time, people think that motorsport is only about entertainment, but it’s also a big laboratory for innovation.”

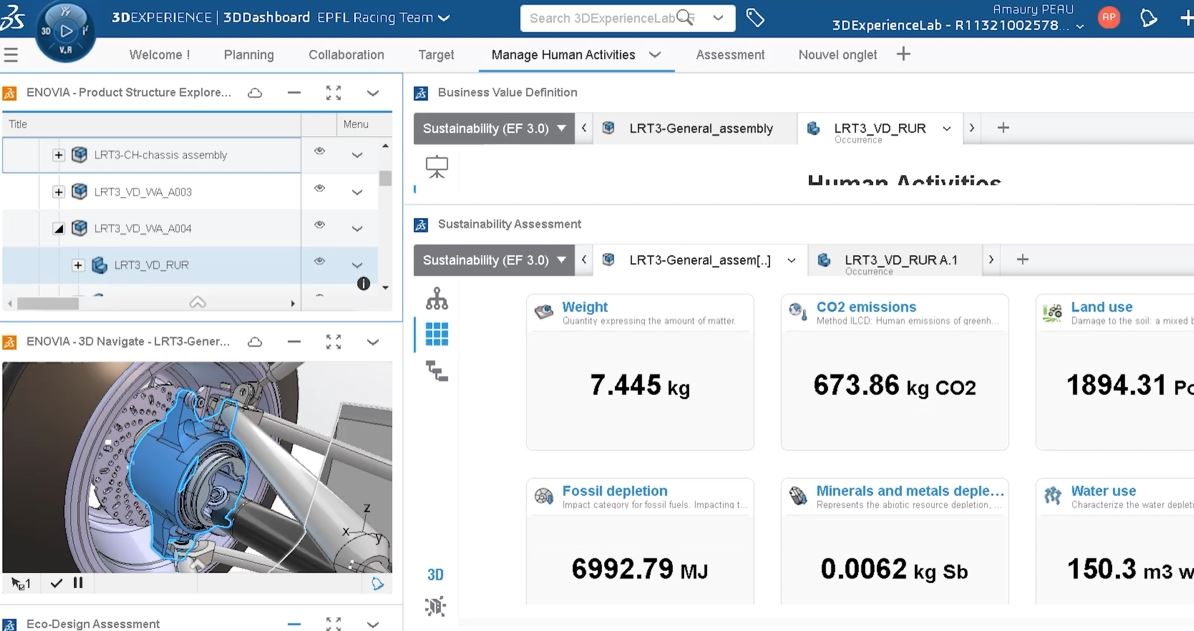

Sponsored by Dassault Systèmes, the EPFL Racing Team uses the 3DEXPERIENCE platform to design and engineer all aspects of its racing cars. Today, it’s also taking advantage of the platform to support its sustainability vision, using the dedicated Sustainable Innovation Intelligence solution to carry out an in-depth lifecycle assessment (LCA) of its competing vehicle.

What is the lifecycle assessment - LCA - and why is it important to EPFL?

The 3DEXPERIENCE platform’s built-in LCA capabilities accurately measure the end-to-end environmental impact of a product. The solution brings together primary and secondary data points from thousands of sources to measure broad sets of impact indicators, from pollution and freshwater ecotoxicity and acidification to energy consumption in manufacturing processes or the use phase of the car and the impacts of human activities, including travel between racing events.

The EPFL Racing Team plans to achieve the following with LCA:

- Make sustainability-driven decisions: Embedding LCA into vehicle design allows the team to evaluate the environmental implications of every component from the onset. They can gain feedback on decisions such as which designs will use fewer materials, or if there is a less pollutant choice for a specific part. They can even compare suppliers, considering factors such as whether they use renewable energy or how carbon outputs will change using different transportation methods.

- Collaborative innovation: LCA brings transparency to the EPFL Racing Team and makes reliable information available to all stakeholders, allowing them to share standardized sustainability data across the product development lifecycle and make truly informed decisions.

- Meet sustainability targets: The EPFL Racing Team will use LCA to meet its own sustainability targets as well as ensure compliance with Formula Student competition standards to develop a competitive and sustainable electric racing car.

- Embed sustainability in Formula E competition: Leading by example, the EPFL Racing Team aims to show how easy it is to integrate sustainability in this sector, and to demonstrate its importance. Through global visibility, they prove to the professionals that even students can integrate sustainability in their teams.

“We want to learn how to reduce our environmental impact through new designs and by exploring new ways of production,” said Savinien Semeria, CEO of the EPFL Racing Team. “And we want to use new materials, which are both highly performant and as sustainable as possible.”

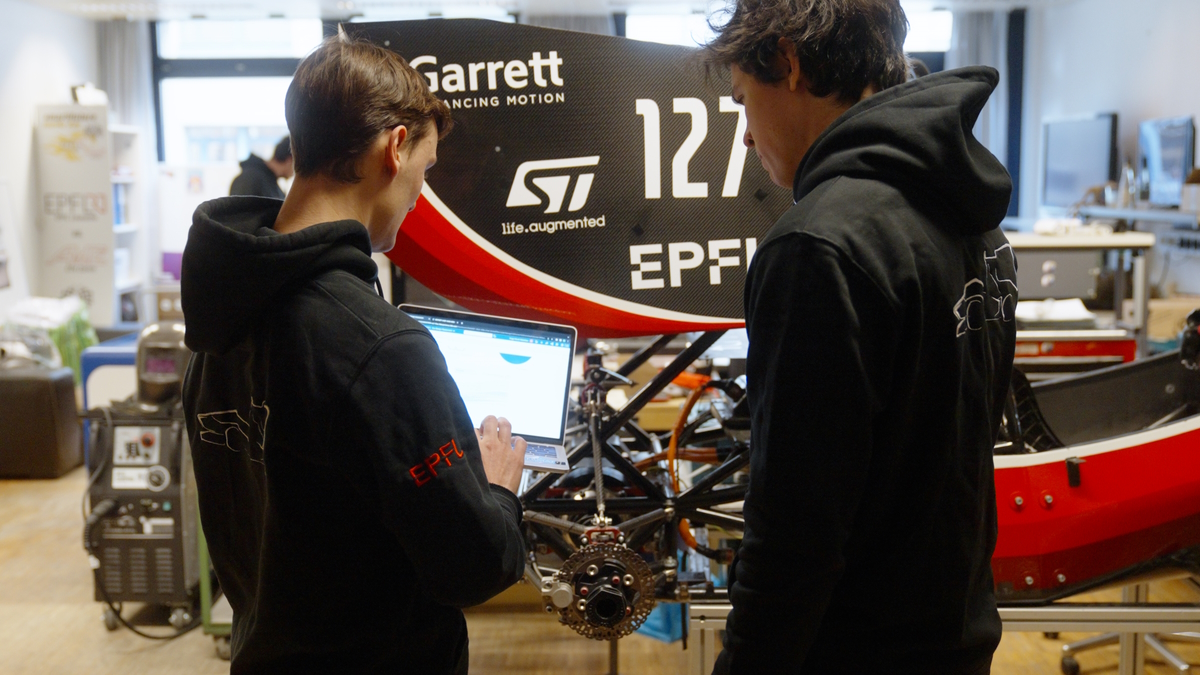

Students access professional tools

The EPFL Racing Team is led by ambitious university students who want to be guided by industry best practices and use professional-standard software to support their environmental agenda.

“We want to be able to go to into the Formula Student competition telling people, “Look what we’ve done and we’re using professional software to achieve it,”” Semeria said. “We wanted to be sure that the metrics we’re working with are concrete.”

Through the team’s partnership with Dassault Systèmes, students are already proficient with the 3DEXPERIENCE platform for managing all design, engineering, simulation and project management processes. They received additional training through Dassault Systèmes’ online learning portal to use the new Sustainable Innovation Intelligence solution. Within hours, Dassault Systèmes experts had showed them what to do and which data they needed to gather, backed by regular meetings to develop their knowledge. Following this training, the students were able to use the tool independently and gained certification as eco-design engineers. This approach will also make it easier to train new users in the future.

“We received training to really understand the solution and then we went away and took the time to master it and build up our skills,” said Thanusya Thambirajah, a member of the EPFL Racing Team sustainability division. “We also had weekly meetings to track progress. With this approach, we were able to carry out the LCA of the car’s steering wheel, seats and upright ourselves. We plan to investigate other parts of the car going forward.”

We’ve received really strong feedback from industry professionals about our sustainability division. They were impressed to hear about what we’re doing and how. It was important for them to see a Formula Student team taking LCA seriously as it’s an area they're focusing on more and more as well.

Concrete metrics steer eco-design

Before they had access to the Sustainable Innovation Intelligence solution, Fenoli-Rebellato and his team carried out manual calculations to begin to determine the carbon impact of the current season’s competition racing car. Their analysis looked at the front left upright of the car and, using their common sense, they estimated the carbon emissions linked to the university facility where they worked and the indirect emissions associated with their activities.

Since using the software, they have been able to more accurately determine the wider environmental impact of their racing car and analyze more parts in a much shorter timeframe. LCA provides a holistic approach by automatically identifying and quantifying carbon, energy and pollution flows at every stage of the studied item’s lifecycle to help avoid pollution shifting and support eco-design decision-making.

“We realized that we had many impacts on the planet, covering more than 15 different metrics, such as water and soil pollution,” Fenoli-Rebellato said. “Lifecycle assessment isn’t 100% perfect. The big benefit of the software is that it reduces this gap of uncertainty so we can better assess the hotspots in the lifecycle and develop a more environmentally friendly design.”

Armed with this new information from the LCA analysis, the EPFL Racing Team is now considering everything from raw materials to production methods as it strives to create a vehicle with the lowest possible environmental impact throughout its lifecycle.

“We want to identify parts in the car that we need to work on,” Fenoli-Rebellato said. “We thought that transport would have a huge impact, but actually the biggest impact in our case was related to the raw materials we use.”

All LCA analysis connects directly to the 3D design models within the 3DEXPERIENCE platform. This means that the students are able to easily compare different components and measure common materials, such as carbon fiber, used in different parts of the vehicle, and see them in the context of the overall design. With this information, they can then weigh up which materials to use and understand the trade-offs between sustainability and performance, so they end up with a car that’s more environmentally friendly but still competitive.

“As well as the upright, we looked at the seat, which is made of carbon fiber like many other parts in the car,” Thambirajah said. “We wanted to know whether the greatest issue was in the sourcing of the materials or in the manufacturing. One interesting find was that wood fiber is 75% less polluting than carbon fiber, yet in this use case it would be unsuitable as it’s heavier and we need the car to be as lightweight as possible to go faster.”

Importantly, LCA is helping the team to understand the full lifecycle of its vehicle and learn how to improve it, from raw materials extraction and production to end of life.

“We can explore the different components, swap out materials and see how they contribute to the overall footprint of the vehicle,” Thambirajah said. “If the raw material is aluminum, for example, we can search for different alloys that may perform better.”

Collaborating for a greener future

By integrating LCA data into the 3D vehicle model on the 3DEXPERIENCE platform, the EPFL Racing Team aims to empower every designer, engineer, logistics expert and business planner to positively influence their organization’s overall environmental footprint. They can collaborate seamlessly on the platform and see the impact of their decisions in a really visual way.

“We all have access to the same information via the 3DEXPERIENCE platform,” Fenoli-Rebellato said. “When we’re talking about a specific part, everyone can view it and understand exactly what we’re trying to assess. It makes it much easier for us to work together.”

This latest initiative is not only raising awareness of the importance of sustainability. It is also bringing the different divisions within EPFL Racing Team closer together, from the aerodynamics and chassis departments to logistics and statics.

“We can easily compare what we’re doing with each other and work towards a common goal,” Thambirajah said. “The platform allows us to make connections between the different divisions and see what data is missing. We can also use the community sharing capabilities where we post a message to the other divisions and quickly get the answers we need.”

We can explore the different components, swap out materials and see how they contribute to the overall footprint of the vehicle.

Achieving high performance and sustainability

Every year, the EPFL Racing Team enters a racing car into the Formula Student Competition. The students are already thinking ahead as to how they can make sure every part and process makes a positive difference, from using more sustainable raw materials to exploring reuse and recycling possibilities.

“We’ve received really strong feedback from industry professionals about our sustainability division,” Semeria said. “They were impressed to hear about what we’re doing and how. It was important for them to see a Formula Student team taking LCA seriously as it’s an area they're focusing on more and more as well.”

Backed by the 3DEXPERIENCE platform and its LCA capabilities, EPFL Racing Team hopes the next vehicle iteration will be more competitive and sustainable.

“Each year is a new chance to improve the car,” Fenoli-Rebellato said. “LCA guides us to design a vehicle that is truly sustainable without compromising on performance. Eco-design is a mindset. In less than a year, we put in place a system to perform an LCA and develop a sustainability strategy. If we can do it, then what are you waiting for?”

Discover more about our sustainability solution Life Cycle Assessment.

00:00 – 00:12

Savinien Semeria, CEO, EPFL Racing Team:

We are the first formula student team to have a sustainability division and we expect a lot from it.

00:13 – 00:19

Hugo Fenoli-Rebellato, Head of Sustainability, EPFL Racing Team:

In less than a year, we achieve to put in place a system to perform an LCA and to make a strategy for sustainability.

00:20 – 00:36

Thanusya Thambirajah, Member of Sustainability Division, EPFL Racing Team:

The LCA assessed through the 3DEXPERIENCE platform was more reliable than the one we did manually as it is a standardized methodology based on scientific data.

00:37 – 00:47

Hugo Fenoli-Rebellato:

Ecodesign is a mindset. No matter the business you are working in, sustainability should always be considered. That's why we have decided to create this sustainability division.

00:48 – 00:58

Savinien Semeria:

The main goal is to be the best into the formula Student competition, but also we want to be more sustainable. We want something very concrete. And LCA is something concrete.

00:59 – 01:28

Hugo Fenoli-Rebellato:

When we did it manually, we mainly focused on carbon footprint, which is a big mistake because sustainability is not only about CO2 emission. And when we accessed the software, we actually understood that we had many impacts on the planet, on more than 15 difference metrics. And we decided to focus mainly on CO2, toxicity, as well as the water and soil pollution, because we think it's where we have the biggest impact.

01:29 – 02:01

Thanusya Thambirajah:

I’ve already knowledge on environmental science and sustainability, but LCA really taught me how to understand the lifecycle of a product. One specific example about the LCA was the one from the seat. If we look at the five phases of the LCA, the raw material is the more impactful one. We compared the carbon fiber and the wool fiber, which is 75% less polluting. But it is not ideal because the wood fiber is heavier than the carbon fiber and the racing car must be lighter to go faster.

02:02 – 02:21

Hugo Fenoli-Rebellato:

The big benefits from the software is to actually reduce this gap of uncertainty. It makes our life easier because we know how to collaborate with other division. So basically the technical division, we’ll model the car and then we can access it in order to assess the impact of the car.

02:22 – 02:46

Savinien Semeria:

Sustainability is now in the DNA of the entire team. We want to learn how to reduce our environmental impact by using new design, finding new way of production, use new materials that are still performant but also sustainable.

Focus on EPFL Racing Team

EPFL Racing Team is a Formula Student team founded by students in 2017. Each year, the team designs and develops an electric racing car. These vehicles are then taken to various competitions around Europe and compete against other universities in engineering and business events.

For more information: https://epflracingteam.ch