ECCUS

ECCUS' mission is to transfer industrial and storage facilities to underground spaces to free up land for nature or other human activities. The swiss startup adopted the 3DEXPERIENCE platform on cloud to support its vertically integrated product development cycle having all disciplines in one place and bring its ECO-Caverne™ to market.

Underground storage frees up land

Data may be digital, yet it has a remarkably physical footprint. There are now more than 8,000 data centers worldwide and at least 600 of these are hyperscale, taking up between 10,000 and 100,000 square feet of land. Insatiable demand for more and larger data centers is leading to increased political pushback, with calls for precious land to be freed up for more beneficial and sustainable uses. Policies across Europe, such as the Swiss Federal Spatial Planning Act (SPA) and Dutch National Spatial Strategy, support this by imposing strict conditions on new building zones.

Andrew Bourget, founder and CEO of Swiss design and build contractor ECCUS, recognizes that limited space is a problem many types of companies now face as they scale up, whether it may be housing an expanding manufacturing plant, storing equipment or finding new logistics sites. His subterranean ECO-Caverne™ solution may be the answer they are looking for.

“I founded ECCUS after reading about a massive data center project in the Zurich area,” Bourget said. “The land surface required was huge and created very few job opportunities. Land scarcity is not only driving up prices, but there is a greater understanding among the general public that land cannot be wasted. With over 30 years in the underground industry, I sought to provide an underground alternative priced on par with a surface solution.”

Targeted at the technology, energy, pharmaceutical, manufacturing and logistics industries, the ECO-Caverne™ is an underground storage facility. Available in three standard sizes, it is suitable for various ground conditions and can be built under existing facilities.

“We have designed the ECO-Caverne™ with three design criteria,” Bourget said. “It should not be visible from ground level; it shouldn’t have any building constraints as it won’t change the characteristics of the site above the ground; and it should be cost and energy efficient to run.”

Sustainability lies at the core of the ECO-Caverne™. Not only is it designed to free up surface land, but ECCUS plans to develop an integrated thermal management system that dispenses heat energy inside the storage unit and captures it for use in the buildings on the surface. This will help to reduce energy requirements in industrial facilities and serve local communities.

“The ground works as an insulator, so we’re looking to turn this heat into a renewable energy source,” said Benoit Cousin, engineer at ECCUS. “We’ll use the ground as a storage medium to cater for seasonal fluctuations in demand.”

Technology advances make the ECO-Caverne™ more feasible too.

“Automated and robotized industrial production methods are the critical enabling technology to ensure widespread adoption of underground infrastructure,” Bourget said. “And then there’s the emergence of new industries which do not require full-time personnel on site, such as data centers and electrical grid-scale battery energy storage. Accessing the value of underground space is essential to our future digital and energy independence.”

Our business is structured to scale up massively, so we also needed a system that would be manageable with a staff of three or 250 without necessitating any change of system down the road.

Powerful and scalable

The ECCUS team is using the 3DEXPERIENCE platform on the cloud to bring the ECO-Caverne™ to life. When Bourget was choosing the technology on which to run his business, he needed a scalable, cloud-based solution that delivered powerful design, geological modeling, simulation and collaborative capabilities. He had the opportunity to test the potential of the 3DEXPERIENCE platform in another project first.

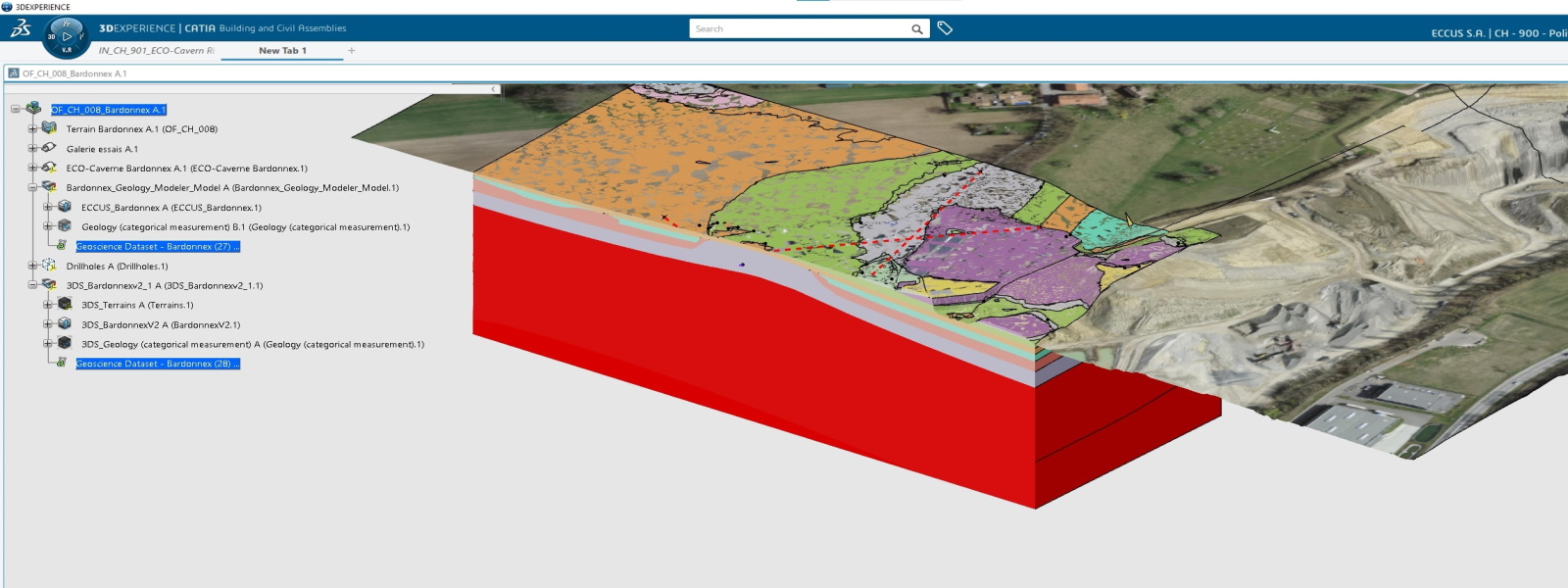

“Before selecting the 3DEXPERIENCE platform for ECCUS, I undertook a proof of concept for CERN’s Future Circular Collider (FCC) Study,” Bourget explained. “Setting up a detailed 40x40 km model, using two national survey coordinate systems, integrating a 3D model of the Geneva basin demonstrated the power of the platform. We could rapidly design underground structures while managing the interaction between geology and civil structures. It also allowed us to embed 2D drawings within the 3D model, enabling dynamic updates to our drawings as alignment options evolve, and full lifecycle management.”

A cloud deployment of the platform also made sense to the startup on many levels, delivering access to enterprise-grade technology without the associated upfront costs.

“Cloud was the obvious choice. It meant we didn’t need an IT infrastructure or services to manage a server and local network, with all the security, IP protection and backup management implications that this would have required,” Bourget said. “Our business is structured to scale up massively, so we also needed a system that would be manageable with a staff of three or of 250 without necessitating any change of system down the road.”

Rapid underground site modeling

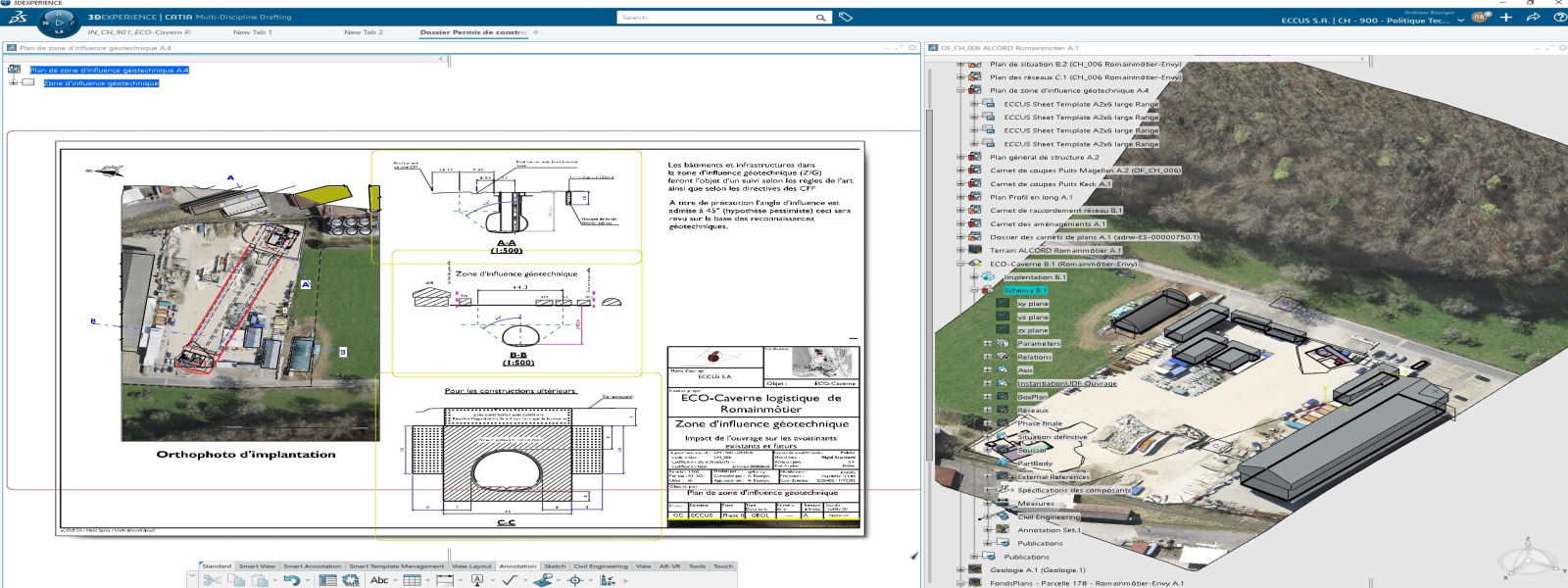

Now that Bourget and the rest of the ECCUS team are up to speed on the 3DEXPERIENCE platform, they can work faster than anticipated and rapidly model new construction environments to determine installation feasibility. ECCUS uses CATIA Civil Engineering and GEOVIA Geology Modeler to create the model of the customer site, including terrain and GIS data.

“Once I’ve checked the ground conditions to allow for the ECO-Caverne™, in that there’s sufficient depth and it’s not in loose gravel, for example, I download from the official sites both the terrain model and the orthophotos and request the layout of all the underground utilities,” Bourget said. “From there, I create the site model with CATIA and use the GEOVIA Geology Modeler to determine where to place the ECO-Caverne™, complete with alignment studies. Within a matter of hours, I end up with a full level of development (LOD200) design of the ECO-Caverne™ on a client site.”

Not only does this save time, but it also helps to secure more potential business.

“The models are invaluable in our discussions with prospective clients and allow us to reach out to more of them at a fraction of the cost of alternative tools,” Bourget said. “It also allows us to continuously refine and add detail to the model, following the building information modeling (BIM) LOD industry standard.”

Bringing together key stakeholders

The 3DEXPERIENCE platform on the cloud is proving invaluable for managing all data within a single environment, which can be accessed online. It supports ECCUS to aggregate multiple stakeholders in each infrastructure project and empower everyone to collaborate.

“Everyone involved can make markups on drawings and models, and it’s all updated in real time,” Cousin said. “For example, we have a partner specialized in data centers and we’ve worked with them on our designs to adapt them for data centers. We are also working with a company in charge of validating the electrical design. All independent electrical engineers and partners have direct access via the cloud to the documents that are relevant to their work with us.”

The robust document management and project capabilities in ENOVIA enable ECCUS to manage the lifecycle of its technical models and documents, but also its financial, commercial and administrative documentation.

“We can quickly and easily cross reference information,” Bourget said. “For example, an invoice can be associated with the hierarchies of the project, the bank from which it is paid, the associated cost center and the supplier.”

ECCUS also uses ENOVIA to track project progress.

“We do our weekly reviews using the tool and we update it directly during the meeting,” Bourget said. “It gives us a great overview of who’s doing what and serves as an effective guideline and memory prompt – helping us to consider issues we’d otherwise not think of.”

With the platform, we can quickly and easily cross reference information. For example, an invoice can be associated with the hierarchies of the project, the bank from which it is paid, the associated cost center and the supplier.

Regulating the ECO-Caverne™

The simulation capabilities in SIMULIA on the 3DEXPERIENCE platform are crucial for modeling the thermal behavior of the ECO-Caverne™, as well as defining the heating, ventilation, air conditioning, and electrical system requirements.

“We use the thermal numerical analysis tools in our design process to reduce energy requirements and ensure the proper regulation of the ECO-Caverne's™ temperature and humidity,” Cousin said. “We’re currently using SIMULIA to determine where to place the ventilators and see what the airflow needs are.”

ECCUS will also use the 3DEXPERIENCE platform to manage all heat, which it will store and distribute as an energy source to users on the surface.

“It is important that we model and simulate the thermal management system on the same platform,” Cousin said. “We’ll use all the insights we have about each ECO-Caverne™ to monitor heat exchange with the underground rock mass to increase the value of the energy we capture.”

Eventually, ECCUS will create virtual twins of its ECO-Cavernes on the 3DEXPERIENCE platform for maintenance and full lifecycle management.

“The ECO-Caverne™ is designed to last for 100 years, and we will use the platform to keep track of each one and carry out predictive maintenance across our entire portfolio,” Bourget said. “If we update certain components because they fail, we will be able to track and replace them in otherECO-Cavernes™.”

It is important that we model and simulate the thermal management system on the same platform. We’ll use all the insights we have about each ECO-Caverne to monitor heat exchange with the underground rock mass to increase the value of the energy we capture.

Championing the 3DEXPERIENCE platform

Through his work on this project, Bourget has been recognized as a CATIA Champion and is an ambassador for Dassault Systèmes’ solutions, working with engineering schools and universities.

“I was invited to join the CATIA Champion program, and the community has provided great insight into certain functionalities,” Bourget said. “As with all mature software, there are many ways to undertake a given task; the trick is to know the easiest and most robust method.”

Bourget and the ECCUS team are also helping to spread awareness of the 3DEXPERIENCE platform on the cloud and prepare students for the working world – critical for recruiting new talent.

“Recruitment is a challenge for any startup,” Cousin said. “Our main challenge is that BIM is relatively new to the civil engineering community. We are encouraging universities and higher education schools to embrace the Dassault Systèmes suite of tools, launching contests and working with students to highlight the platform’s capabilities. We want them to learn by doing.”

Underground potential

As Bourget and his team bring the ECO-Caverne™ to market, they are benefiting from the rich expertise within Dassault Systèmes and its online community to share ideas and address any issues that come up along the way.

“The IFWE loop has proven extremely important to us,” Bourget said. “It directly links us to Dassault Systèmes experts and allows us to trace our discussions without any intermediary. Furthermore, it is invaluable to Dassault’s R&D in that it helps them identify any issues with the tools we use and provides a robust understanding through our use cases. We then benefit from new functionalities and upgrades in the next release.”

Looking ahead, Bourget is excited about the potential of the 3DEXPERIENCE platform and how it can help transform his industry for the better.

“The domain of underground structures is the orphan of the BIM revolution and Dassault Systèmes has picked up the gauntlet. I’m seeing profound improvements in the tools dedicated to the combination of geology, civil engineering, and road, rail and metro alignment capabilities,” he concluded. “Any company whose core business is in underground structures needs to pay attention to what Dassault Systèmes is doing.”

Discover additional insights from a SIMULIA user.

Discover more about the From Experience to Construction industry solution experience.

Focus on Eccus

ECCUS is a Swiss startup founded in 2020 by Andrew Bourget, a civil engineer with more than 30 years of experience in underground construction. The company is made up of a team of engineers specialized in civil engineering, geothermal energy, heating, ventilation, automation and electricity. ECCUS’s mission is to transfer industrial and storage facilities to underground spaces and free up land for other uses. To achieve this goal, ECCUS develops standard cavern designs which can be built under existing facilities and are suitable for various ground conditions.

For more information: www.eccus.ch