DFAC made a comparison designing a van using the 3DEXPERIENCE platform, and a truck without using the 3DEXPERIENCE platform.

DFAC discovered that using the platform led to

increase in efficiency in the design process

decrease in design problems

A new R&D platform for truck innovation

When most businesses embark on a digital transformation, quantifying the return on investment can be challenging, especially early in the journey. Many don’t have the time or resources to test and compare new technology in parallel with their existing approaches. Yet, that’s exactly what Dongfeng Automobile Corporation (DFAC) did, and the results are remarkable.

A subsidiary of Dongfeng Motor Corporation, DFAC is one of China’s largest commercial vehicle manufacturers. It recently launched a new leadership plan to strengthen its position in the industry and boost the research and development (R&D) capabilities of its light commercial vehicle business. At the heart of this vision was the rollout of a new R&D platform, which would serve as a centralized environment for managing all aspects of the product development lifecycle.

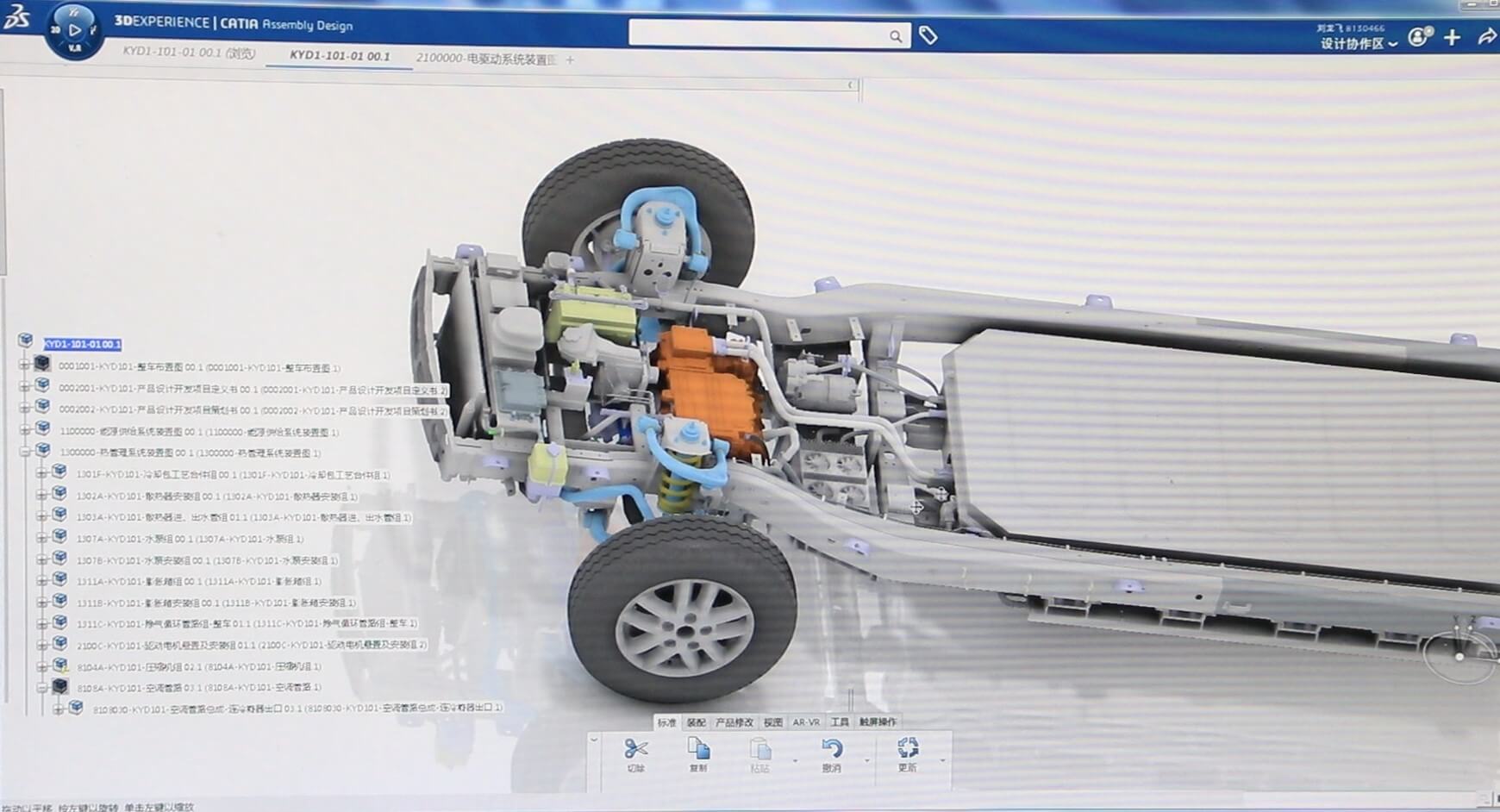

The company had two new vehicles to develop – a van and a truck, both using renewable energy. DFAC decided to design the van using CATIA on the 3DEXPERIENCE® platform, and the truck using its traditional approach to determine the difference between the two. DFAC hoped the 3DEXPERIENCE platform would save time and was impressed by the outcome.

“The collaborative design process for the van on the 3DEXPERIENCE platform was 30% more efficient compared to the truck,” said Li Fei, section chief of the Chassis Development Department at DFAC. “The ability to integrate electrical design into the same 3D model while leveraging the single data environment provided by the 3DEXPERIENCE platform also meant we encountered as much as 70% fewer design problems. The quality of our design improved significantly.”

Clear benefits from centralized product data

Like many established businesses, DFAC’s growth over the years led to the implementation of multiple systems and tools to suit the specific needs of its different departments. Even within design, teams used different applications.

“We had two separate CAD tools in use, and it meant we constantly had to convert data formats as we switched between them,” Fei said. “During the conversion, some parameters were bound to get lost, and then we had to organize the data. This impacted our efficiency.”

“Switching between data formats was very difficult and time consuming,” added Qiang Xiaowen, president of the Product R&D Institute at DFAC. “There was no way to achieve online collaborative design unless we unified the data source.”

The van development team soon found that the 3DEXPERIENCE platform’s unified data environment presented obvious advantages. Structural designers and general layout engineers could share data in real time and collaborate on the same 3D models without the need to switch between applications or convert data files. This helped to accelerate the R&D cycle, improve data quality, keep costs under control and launch the new van to market faster than ever before.

“The main purpose of the 3DEXPERIENCE platform is to improve our R&D efficiency by standardizing our processes, centralizing our data and providing management full visibility into what’s happening across the business,” said Zhang Jingfeng, general manager assistant at DFAC. “The R&D platform needed to be able to manage and assimilate data in real time.”

“With the new platform, R&D will provide high quality product data to support DFAC’s whole value chain,” added Chai Shujun, director of the Engineering Verification Center at DFAC. “This will substantially improve product development quality, shorten the development cycle, and reduce costs.”

With the 3DEXPERIENCE platform, we can reduce costs by improving R&D efficiency and product quality, as well as accelerating product launches. In turn, those savings get passed on to our customers.

Designing vehicle parts in context

While DFAC’s traditional approach had made it impossible to see a full picture of the vehicle early on, this wasn’t the case for engineers using the 3DEXPERIENCE platform. The van team was able to design the vehicle body, chassis and electrical equipment, including interior and exterior components, in parallel within a single data environment with full version control. Robust change management, thanks to ENOVIA, helped to avoid errors and rework. Designing in the context of the entire vehicle framework kept individual departments on task, too.

“Each system engineer can update their own models online and in real time, while the general layout engineer can see the live model status,” said Liu Longfei, chief engineer for vehicle model general layout at DFAC. “It helps us identify the layout boundaries of each specialty when planning the framework model, which significantly improves efficiency.”

ENOVIA also keeps data management under control. Every model is stored with a unique part number under a unified specification within the 3DEXPERIENCE platform.

“Engineers design structures and parts, such as the chassis and electronics, around that framework,” Fei said. “They can see all the connected components around them and use them as a reference to design their own parts.”

Beyond the design department, other employees across DFAC without CAD experience, including management, can also log onto the 3DEXPERIENCE platform and check the live status of designs, helping to detect potential issues early on and keep projects on track.

“Management can see how the design has progressed,” Xiaowen said. “It provides good, user friendly support for non-designers to view projects and learn about project progress.”

Furthermore, DFAC is beginning to benefit from centralized data management on the 3DEXPERIENCE platform. Over time, the company plans to apply data analytics to improve the way it gathers and makes sense of the exponential data it generates.

“Our aim is to accurately share, visualize and analyze our data to support intelligent decision-making,” Jingfeng said. “In future, once we’ve accumulated a large amount of data, we’ll be able to determine what will bring new value to the company. For example, we can use data to discover where to invest more manpower and how best to allocate human resources during the project planning stage.”

Customer-centric design

Buoyed by the success of developing its skateboard chassis van on the 3DEXPERIENCE platform, DFAC is now looking to embrace a more customer-centric design approach, where its customers’ specific demands are factored into the vehicle design as early as possible.

“We’re looking at how, for example, we can capture design requests and features specified by our customers and integrate them into the vehicle development from the onset,” Jingfeng said. “This will demonstrate DFAC’s product development capabilities and bring us closer to the market and our customers.”

DFAC recognizes that the logistics industry it serves is becoming more competitive and it must take further steps to ensure its commercial vehicles stand out in the market. They need to exceed customer expectations around innovation, reliability and cost effectiveness.

“We must help our customers get the most from their vehicles,” Zhang said. “We need to be able to calculate the total cost of ownership and find ways of bringing it down as much as possible. With the new product data management platform, we can reduce costs by improving R&D efficiency and product quality, as well as accelerating product launches. In turn, those savings get passed on to our customers.”

Accurate data supports DFAC's value chain

DFAC has already made significant progress in its digital transformation journey. The company’s success has undoubtedly been down to its unwavering commitment and the huge effort within the R&D team to transition all processes and related data to the 3DEXPERIENCE platform. These include multiple projects and as many as 100,000 tasks within those projects, such as assigning a designer to a particular detail within a digital mockup.

Eventually, the DFAC product development environment on the 3DEXPERIENCE platform will bring together modular collaborative design, project management, knowledge engineering, digital mockup and product data management.

“As a manufacturer of commercial vehicles, we must use data to improve our process costs and increase our revenue,” Zhang said. “In the future, we hope to connect our entire business on the 3DEXPERIENCE platform and use those data insights to find out what brings new value to the company.”

This is only the beginning as DFAC now explores how to harness more of the 3DEXPERIENCE platform’s applications to continuously improve the efficiency of product design, simulation, and manufacturing. Through better collaboration, the company hopes to create an innovative research and development model that is more user friendly and adaptable to rapid market changes.

Discover more about the Global Modular Architecture industry solution experience.

00:00 – 00:35

Zhang Jingfeng, General Manager Assistant, DFAC:

Commercial vehicles are tools for production, and they're meant to generate income. So our commercial vehicles need to perform well, and be reliable. We need to analyze our clients' perspective, to weigh the total cost of ownership(TCO) against his expected income to be earned from using our vehicles. The benefits must outweigh the cost.

00:36 – 00:54

Li Fei, Section Chief, Chassis Development Department, DFAC:

We designed a van on the 3DEXPERIENCE platform, and a truck in the traditional way. The team using the 3DEXPERIENCE platform proved to be 30% more efficient in designing the van.

00:55 – 01:18

Qiang Xiaowen, President, Product R&D Institute, DFAC:

Before using Dassault Systèmes' 3DEXPERIENCE platform, our R&D institute faced many major challenges. First, our software systems were not unified. Different people worked on design and development in multiple systems, so data switching was very difficult and time-consuming. Also, we could not collaborate on design online.

01:19 – 01:37

Li Fei:

After integrating electrical assembly and calibration on the 3DEXPERIENCE platform, we found that the van had 70% fewer design problems than the truck, as our designs are now unified. There's less data conversion between CAD models, improving design quality and efficiency.

01:38 – 01:55

Qiang Xiaowen:

The 3DEXPERIENCE platform, has enabled our designers to work with a modular thinking right from the start. Rather than designing and developing specific parts, we will be more focused on improving overall performance.

01:56 – 02:28

Liu Longfei, Chief Engineer, Vehicle Model General Layout, DFAC:

We used to edit and modify the specific models of each system locally so we had to double check the details, which wasn't efficient. Now with the 3DEXPERIENCE platform, each system can update its own models online in real time, and the general layout engineer has an accurate overview. Each department can edit the model's hierachical structure such as part number, so we have fewer errors and spend less time solving problems. This has effectively improved our general layout efficiency.

02:29 – 02:44

Zhang Jingfeng:

In the future we plan to accumulate all data on the 3DEXPERIENCE platform to find out what brings new value to the company.

Focus on Dongfeng Automobile Corporation

Dongfeng Automobile Corporation is part of Dongfeng Motor Corporation, founded in 1969 and is one of China’s largest automobile groups. Its main business covers commercial vehicles, passenger vehicles, auto assemblies, parts and components, machines and equipment, and other automobile-related products and services. After more than 49 years of development, the company has become an industrial leader in R&D, manufacturing and marketing.

For more information: www.dongfeng-global.com