Dhaksha Unmanned Systems

Indian drone company Dhaksha Unmanned Systems implemented the 3DEXPERIENCE platform on the cloud as a scalable technology platform for effective collaboration. With industry solution experience Reinvent The Sky, Dhaksha has been able to meet stringent industry regulations and almost double its production of specialist drones such as agricultural drones.

Transforming farming with agricultural drones

Spraying fertilizers on crops with handheld machines is time-consuming and labor-intensive. It can take farmers in rural areas of India several hours to cover just one acre of land.

New agricultural drone technology is changing the game, reducing hours of work to minutes and facilitating the use of cutting-edge nano-fertilizers that, thanks to their smaller particle size, can penetrate roots and leaves more effectively than traditional chemical solutions. With less fertilizer required, farmers using drones can minimize their impact on the environment and save significant sums of money.

“With the vast agricultural landscape in India, drones can help increase productivity, optimize resource utilization and reduce operational costs for farmers,” said Krishnakumar Ramaraj, chief technology officer at India-based Dhaksha Unmanned Systems, a company established in 2019 at Anna University MIT’s Center for Aerospace Research. “At the same time, they can reduce fertilizer consumption and limit humans’ exposure to pesticides.”

Dhaksha develops these agricultural drones (locally referred to as ‘Kisan’ drones, after the Hindi word for famers), as well as specialist drones for defense, surveillance and mapping. Among its Kisan drones are three different solutions for crop spraying: a hybrid-powered medium-sized drone and two battery-powered drones; a smaller variant that can cover two acres of land on a single charge which lasts for around 18 minutes; and a larger drone that can fly for around 25 minutes, even with a full load. Dhaksha has advanced the development of these drones, and rapidly brought them to market, thanks to Dassault Systèmes’ 3DEXPERIENCE platform on the cloud.

The 3DEXPERIENCE platform offers robust data management capabilities, which include secure data handling, version control and audit trails.

A platform for collaborative drone development

Dhaksha was already familiar with Dassault Systèmes’ design tools. It had used Anna University MIT’s CATIA licenses right at the outset, which allowed it to shape the early stages of its drones.

However, as Dhaksha evolved into an independent private limited company and grew its various design and engineering teams, its requirements changed.

“Administering our standalone on-premises solutions was becoming time-consuming and complicated,” Ramaraj said. “Managing the licenses and updates was a challenge. It was also difficult for users to collaborate with distributed teams and partners across different locations. That’s why we decided to explore a cloud-based solution.”

The 3DEXPERIENCE platform on the cloud emerged as the most compelling option. Ramaraj and his team were impressed by its collaboration features, which would allow team members and external partners to work together seamlessly on design projects from anywhere with an internet connection.

The Dhaksha team also valued the platform’s ability to scale as it grew, without any complex licensing requirements – a necessity for the company to remain agile so that it can compete in India’s drone market, which is expected to grow to around $4.2 billion by 2025.

“With the 3DEXPERIENCE platform on the cloud, I can easily scale up my usage to meet a growing number of orders from companies in agriculture and defense, as well as enterprises,” Ramaraj said. “These will be used for a wide range of purposes including surveillance, monitoring floodplains or power lines, providing agricultural drone software that includes mapping services for urban planning as well as logistics. We can fulfil these orders without worrying about hardware or software limitations.”

This flexibility is crucial as Dhaksha’s business grows and further diversifies into new product lines and drone applications such as swarm drones, which is a cluster of networked drones working together to complete surveillance or search and rescue tasks, for example, and the use of which accomplishes the task faster than a single drone.

Dhaksha sought support to implement the 3DEXPERIENCE platform for Startups offer, which is designed to support early-stage startups with the product development solutions they need in the long term.

EDS Technologies configured a dashboard that provided users with a customized view of the apps and data that were most important to their daily work. EDS also provided end-to-end support and training. This enabled Dhaksha to benefit from the full potential of the 3DEXPERIENCE platform in just a few weeks.

Creating robust drone designs

The 3DEXPERIENCE platform on the cloud now provides Dhaksha’s internal teams and external partners with a common framework through which they can collaborate on product designs.

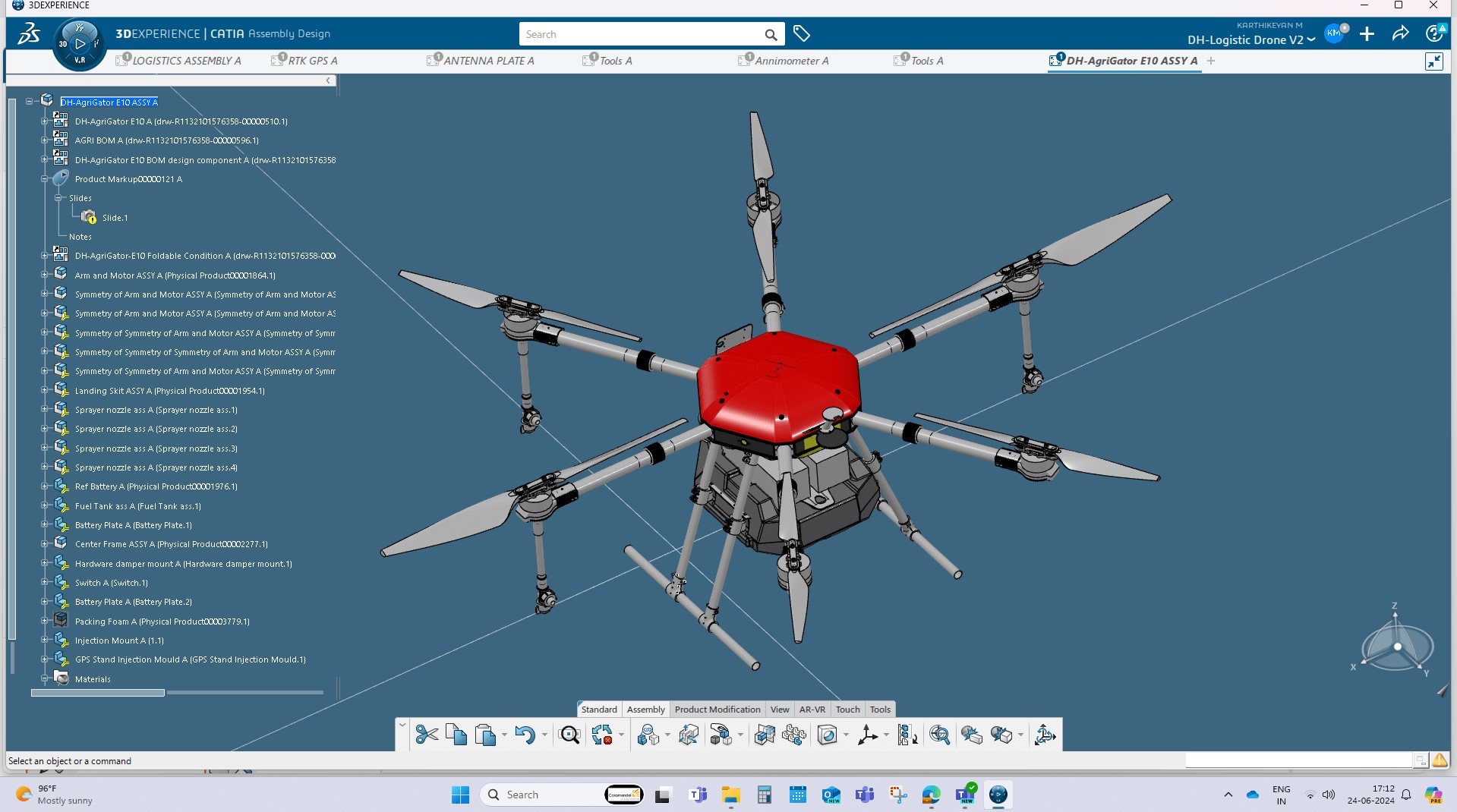

CATIA’s instant availability on the platform, along with EDS Technologies’ support in streamlining the design process, meant Dhaksha’s designers could quickly begin working in CATIA to engineer the entire structure of their drones.

“We have been able to design a precise model of all mechanical parts, including the chassis, motor mounts and landing gear,” Ramaraj said. “These components are made from various materials, including plastics and composites. To create these surfaces in the platform, and evaluate how they interact with each other, users can leverage various tools within CATIA.”

Once the various mechanical parts have been developed, designers can use CATIA for assembly modelling so that they can visualize the drones in their entirety and validate their effectiveness prior to manufacture. They can also quickly share and reuse existing designs and components in new iterations, speeding up the drone design process.

The 3DEXPERIENCE platform’s flexibility is crucial as Dhaksha expands its business and explores product diversification.

Expediting the regulatory approval of drones

Dhaksha’s innovation capabilities have yielded pioneering results. It recently became the first and only drone manufacturer to achieve Type Certification from India’s Directorate General of Civil Aviation (DGCA) for four different drone models that are used for agriculture, mapping and surveillance applications.

“Type Certification is effectively a certification for airworthiness,” Ramaraj said. “This isn’t easy to achieve. In India, regulatory frameworks are evolving rapidly to address the proliferation of unmanned vehicles and ensure their safety and compliance.”

For Dhaksha to achieve Type Certification, it needed to demonstrate the integrity of its drone designs and meet various guidelines concerning operational limitations, safety features and pilot training requirements. “It’s a complex and rigorous process requiring extensive documentation, testing and evaluation,” Ramaraj said. “It involves multiple stages, including design reviews, prototype testing and operational assessments.”

Navigating through these stages – while crucial to ensure the safety, reliability and acceptance of drones – is undeniably time- and resource-intensive. However, by leveraging ENOVIA’s product lifecycle management capabilities, Dhaksha has been able to offload some of the burden.

“ENOVIA on the 3DEXPERIENCE platform offers robust data management capabilities, which include secure data handling, version control and audit trails,” Ramaraj said. “This ensures that all modifications are tracked and that there is a clear record of who made changes and when. This is crucial because we must supply all the design documents concerning our drones to the regulator to achieve Type Certification.”

We used to be able to assemble five or six agricultural drones per day. That’s now gone up to 16 to 18 drones per day.

Increasing manufacturing output

The benefits of the 3DEXPERIENCE platform are being felt right through to the manufacturing stage.

ENOVIA provides a consolidated and accurate bill of materials and a common, automated change process to maintain accuracy. Since moving from CATIA V5 to the 3DEXPERIENCE platform and its suite of solutions, Dhaksha has increased productivity and more than doubled its production.

“Thanks to the platform, we are reducing errors and rework, thereby improving productivity,” Ramaraj said. “We used to be able to assemble five or six agricultural drones per day. That’s now gone up to 16 to 18 drones per day,” Ramaraj said. “We’ve also improved the output of the drones we are developing for defense. These are bigger machines weighing around 110kg. Output has increased from two or three a day to eight.”

Dhaksha isn’t resting on its laurels. It has already received orders for over 1,400 of its existing drones and is working on creating higher endurance models that can carry a payload of 100kg for a flight time of eight hours. It is also developing drones that can provide up to 16 hours of surveillance with a range of 200-300km.

Realizing new efficiencies with virtual drone testing

Ramaraj recognizes Dhaksha can leverage further functionality from the 3DEXPERIENCE platform to achieve this growth. For example, much of company’s current testing phase involves the use of physical prototypes.

“Once we have designed our drones, we currently go straight to fabrication and then field testing,” Ramaraj said. “If there’s a fault, the entire thing will be damaged – including any payloads. We then must make changes to the design and start again. This can create huge setbacks, both in terms of time and cost.”

This manual approach also makes it difficult for Dhaksha to ensure its drones are fit for purpose. “Different customers have different requirements. They may want to fly a drone at an altitude of 4,000m above sea level. Since our offices are situated in Chennai, which is at sea level, it is very difficult for us to test our drones under the conditions in which they will operate.”

By using SIMULIA to validate the performance of its drones in the virtual world, Dhaksha can solve these challenges. It can discover how its drones will perform under a variety of conditions and only proceed to physical prototyping once it is confident its products will work as intended.

“As we begin using SIMULIA for structural validation, we expect to accelerate the design cycle, prototyping and testing phases,” Ramaraj said. “Simulation will allow for faster iterations. We will also reduce our reliance on physical prototypes, saving significant sums of money.”

In addition, Dhaksha hopes to explore some of the 3D printing capabilities of DELMIA, so that it can create prototypes in a more efficient way and further reduce costs. It is also planning to expand its use of CATIA for composite and electrical harness design, as well as for explicit dynamic analysis and vibration analysis.

“The comprehensive nature of the 3DEXPERIENCE platform will continue to benefit us as we evolve,” Ramaraj said. “I look forward to seeing what we can accomplish as we leverage more of what it has to offer.”

Discover more about the Reinvent The Sky industry solution experience.

Focus on Dhaksha Unmanned Systems

Dhaksha Unmanned Systems addresses the growing demand for advanced drone technology, providing cutting-edge solutions such as agriculture drone services to handle socio-economic challenges and meet the evolving needs of society. In April 2019, Dhaksha officially became an independent private limited company, founded by MIT alumni. Today, Dhaksha is an exclusive strategic partner of Anna University, driving R&D, manufacturing, and marketing drones for the global market. Its state-of-the-art factory and research and development center, which is situated in Chennai, serves as a hub for innovation and excellence.

For more information: https://dhakshadrones.com/

Focus on EDS Technologies

EDS Technologies is one of the largest engineering and visual simulation solutions providers in India. With over two decades of experience in various industries, the company enables businesses in the aerospace, automotive and supply chain, industrial machinery, high-tech and electronics, railways and infrastructure to achieve their business goals. Headquartered in Bengaluru, EDS Technologies has a direct presence in 9 cities across India, serving more than 1,500 customers with PLM, visual simulation, e-learning and 3D printing solutions.

FAQ about agricultural drones

Agricultural drones are used to spray nano-fertilizers that, because of their smaller particle size, can penetrate roots and leaves more effectively than traditional chemical solutions.

In areas with a vast agricultural landscape such as India, agricultural drone technology can help increase productivity, optimize resource utilization and reduce operational costs for farmers. At the same time, they can reduce fertilizer consumption and limit humans’ exposure to pesticides.