csi entwicklungstechnik

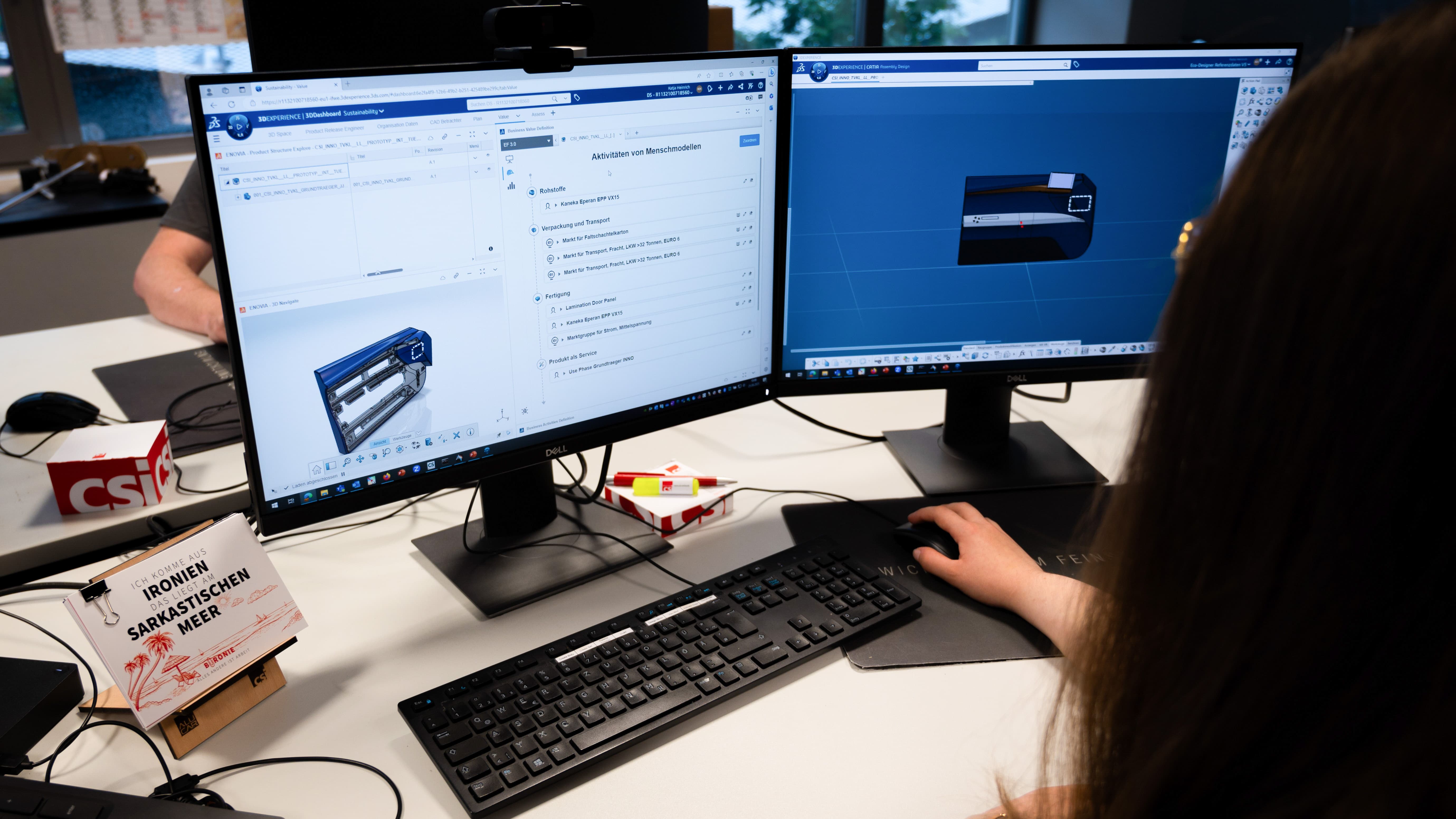

German engineering services provider csi entwicklungstechnik adopted the 3DEXPERIENCE platform and its cloud-based sustainability solution to embed Life Cycle Assessment into a virtual twin to support the eco-design process for its customers which include international automotive OEMs.

The push towards a more sustainable automotive industry

Executives at Germany-based csi recognize that sustainability is far more than just an exercise in ticking boxes – it’s a business strategy that, when done right, can open up significant opportunities for business growth.

That’s why it is helping to steer automotive firms away from greenwashing by creating mobility services and products that are genuinely environmentally friendly, prioritizing sustainability from the very outset.

To understand the environmental impact of a product throughout every phase of its life, automakers need to carry out Life Cycle Assessment (LCA) studies. This holistic methodology considers all of the environmental impacts of a design, from raw material extraction, to resources, energy, waste used or generated throughout the manufacturing, packaging and distribution process; impacts from the using the product; as well as impacts from the recycling or the disposal of its various components at its end of life.

Ultimately, this type of analysis identifies the systems or lifecycle phases that have the biggest impact on sustainability. However, LCA needs to be more straightforward. That’s why csi offers solutions to help its customers easily implement sustainable product development processes from the very beginning.

In our view, Dassault Systèmes’ cloud-based sustainability offering stands out from conventional LCA tools thanks to its interface with multi-CAD design tools including CATIA. It’s easy to handle and concept comparisons are visual, so they are better communicated to the customer. With everything we need available via a single platform, we can maintain our position as a trusted partner for OEM customers, helping them develop highly sustainable products.

Challenge

In the past, sustainability requirements have typically been considered too late in the automotive development process – if at all. However, for promising transformation, ‘green’ products need to be designed from the get-go. This requires automakers to reevaluate everything from their cars’ initial design and engineering stages, through to production and delivery, as well as operations, servicing and end-of-life.

csi prides itself on the use of advanced digital technologies to uncover the best opportunities for its clients. These technologies include artificial intelligence, virtual prototyping and digital twins. Wanting to add LCA to this list, it sought a technology partner that could help it become a competent partner for OEM customers in the development of sustainable products and in calculating their carbon footprint.

Acknowledging that 80% of a product’s environmental impact is determined during the design phase, it began the search for a solution that would enable it to embed LCA into the first stages of the product development process.

Solution

csi conducted a thorough review of the solutions available on the market. It found that conventional LCA tools had limited value because they could only measure the impact of what had already been manufactured. However, LCA as part of virtual twin technology makes environmental assessments available from the point of ideation, and then to every member of the innovation process downstream.

Following a strong value demonstration from Dassault Systèmes partner CCS Service GmbH, the 3DEXPERIENCE platform, along with its cloud-based sustainability solution, which includes multiple brands such as ENOVIA, NETVIBES and CATIA, stood out as one of the most compelling examples of how LCA could be embedded within the virtual twin.

The 3DEXPERIENCE platform links sustainability to other enterprise processes like requirement management, change management and task management, thereby establishing digital continuity across an organization’s processes. As a longstanding CATIA V5 user, CSI was also impressed by the platform’s ability to interface with multiple product structures from multi-CAD scenarios like CATIA and SOLIDWORKS.

Benefits

Working closely with Dassault Systèmes and CCS, csi has implemented the solution quickly. Over the coming months, it expects to realize many benefits.

With digital continuity between engineering and LCA, csi anticipates that it will be able to enrich its virtual twin with environmental insights that will result in improved collaboration and more effective decision making around sustainability. This will help instill sustainability and its importance for the success of product needs into the minds of everyone involved in a project. It will support an eco-design process for the customer at the earliest stage of product development and, at the same time, optimize operations and enable sustainability targets to be met.

What’s more, digital simulations will allow for the fast evaluation of different scenarios, without the need to build expensive prototypes. This not only enables csi’s automotive clients to enhance their sustainability strategy, but also helps them drive down production costs and shorten the time to market.

Discover more about our sustainability solution Life Cycle Assessment.

Focus on csi entwicklungstechnik

Germany-based csi has been a reliable partner to leading automotive firms for over 25 years. It provides engineering services to transport and mobility OEMs with construction and project management expertise covering A-class areas (freeform surfaces such as bumpers and dashboards), body work, lightweight construction, interior, exterior, electrics/electronics and simulation. The well-qualified engineers of csi provide OEMs with various services that aim to accelerate product innovation.

For more information: https://www.csi-online.de/en/home

Focus on CCS

CCS is a trusted Dassault Systèmes partner with sound process understanding. Its value engagement and design thinking approach has led to its strong reputation across industries including automotive, aviation, mechanical engineering and plant construction. Its solutions include software, hardware, implementation, training and support.

For more information: http://www.ccs-service.com/