CenterLine Windsor Limited

Canadian industrial automation process and technology company CenterLine (Windsor) Limited aimed to optimize robotic work cell designs through digital simulation prior to deployment of physical equipment on factory floors.

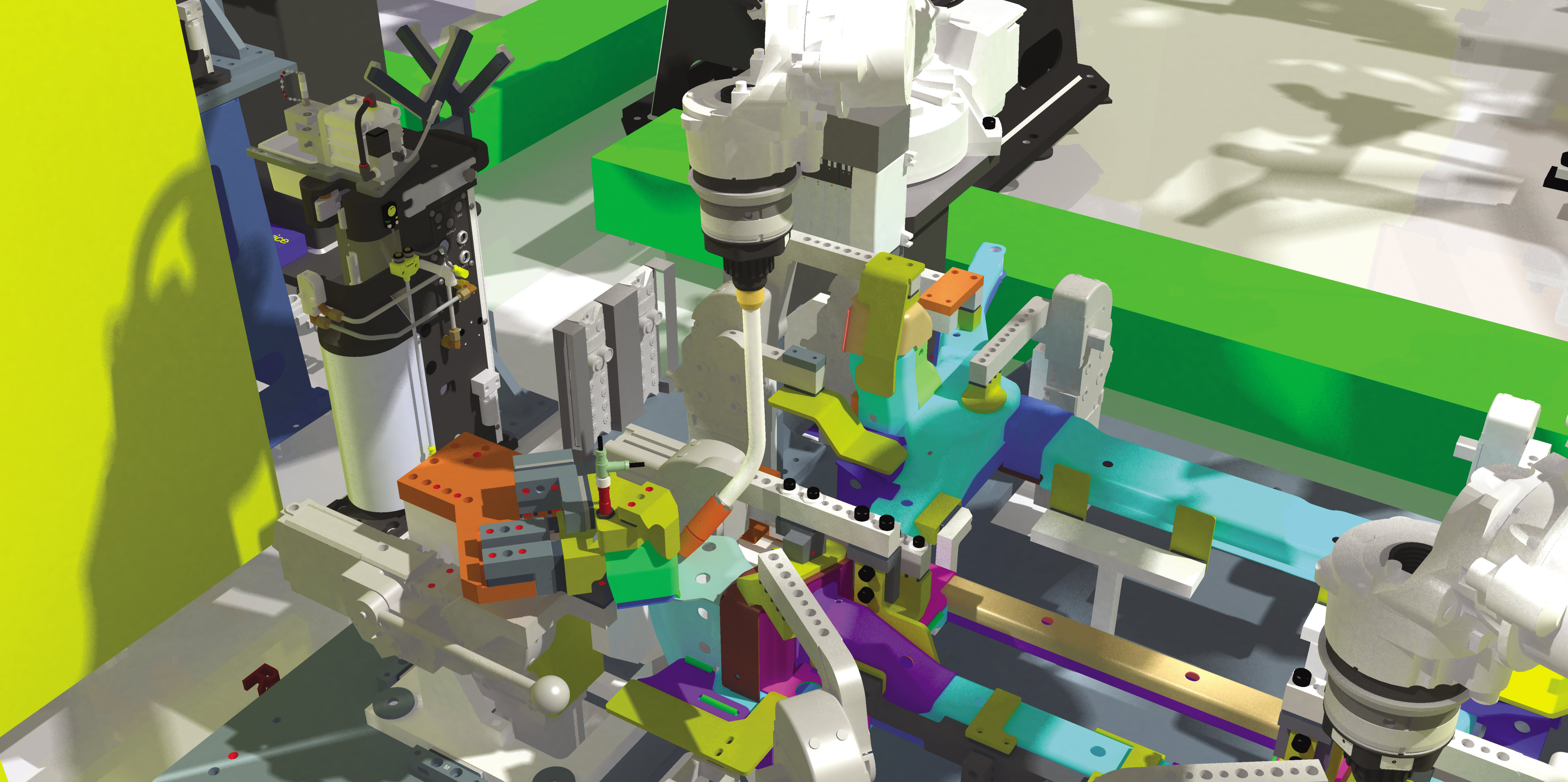

Saving deployment dollars with robotic work cell simulation

No manufacturer wants to deploy equipment on its factory floor only to discover that the swing of a robotic arm will bump into an adjacent machine, or fail to reach the object it’s supposed to manipulate, or in any way endanger a worker. Factory setups can cost millions of dollars, and the most expensive time to fix design errors is after built-out systems physically exist.

As a provider of advanced production and technologies, Canadian-based CenterLine (Windsor) Limited innovates better ways for manufacturers to avoid costs, maximize productivity and accelerate time to market. CenterLine specializes in advanced automation processes and joining technologies for resistance welding, metal forming and cold spray applications. Its vertically integrated product offerings range from welding consumables to fully automated production systems.

“Our customers value the fact that we’re going to give them good equipment but also they’re looking for us to provide systems that are going to make them competitive and keep production going,” said Marc Levesque, director of corporate marketing at CenterLine (Windsor) Limited. “The systems CenterLine designs require little maintenance and are often designed to enable them to be scaled up if the production requirements are increased.”

Since CenterLine’s inception in 1957, the company has seen massive changes in the industries it serves. In recent years, its main customers – original equipment manufacturers (OEMs), the Tier 1 and 2 suppliers, and machinery integrators in the automotive, mass transit, aerospace and defense industries – have seen consolidation, new technologies, new industry players and the rise of competition. CenterLine views simulation as a competitive necessity.

“Over the past 12 years, there’s been a significant shift in the way companies view simulation,” Luciano Mancini, robotics simulation lead at CenterLine (Windsor) Limited, said. “We used to simulate maybe one or two robot work cells, or it used to be done on the floor. Today, we simulate and understand every robot, every process and every piece of machinery before it’s on the floor. We can design, build and manufacture something upfront in a digital world rather than design, build it, then run into issues on the floor and have to redesign significantly.”

Our customers value the fact that we’re going to give them good equipment but also they’re looking for us to provide systems that are going to make them competitive and keep production going.

A competitive necessity

To meet its simulation goals and customer’s needs, CenterLine chose DELMIA Robotics on Dassault Systèmes’ 3DEXPERIENCE platform to enable creation of digital models that virtually simulate products, processes and factory operations. DELMIA allows CenterLine to visualize and verify robot movements to optimize use of shop floor space, material flow and ergonomic safety.

“DELMIA Robotics helps us visualize and conceptualize our designs before they’re manufactured on the floor,” Mancini said. “That helps us resolve issues upfront and gets the product out right the first time. DELMIA Robotics allows us to give our customers peace of mind. By building virtually, we demonstrate that we can produce their complicated systems on time and on budget, and exactly how it will improve their operations.”

CenterLine has already experienced impressive success by utilizing DELMIA on robot work cells. “Since implementing DELMIA Robotics for every work cell that contains a robot, we haven’t had to move a single robot on the floor,” said Mancini. “That’s a significant time savings. We have reduced our tooling-related issues and rework by up to 90%, and our programming time on the floor has been reduced by as much as 75%.”

Mancini says that CenterLine is completing offline programming (OLP) in DELMIA Robotics. By transferring robot system programs to the factory floor and the robot without tying up physical resources on the floor, they are seeing substantial time savings in the commissioning phase.

“DELMIA OLP has cut down our teach time on the floor significantly,” Craig Clayton, robot simulation technician at CenterLine (Windsor) Limited, said. “It’s a great tool when we download a program or when we get reengineered jobs and need to upload robot paths to make sure the fixtures are actually where a 2D footprint says they are. If we didn’t give them a path they would have to decide the order of, say, welds. With DELMIA OLP, we can switch that around easily and then give the floor the actual path so they don’t have to worry about sequencing.”

CenterLine also uses simulation to show customers how new products and processes can give them a competitive advantage prior to purchasing.

“We’ve used DELMIA Robotics to showcase innovative products from our mechatronics and gun divisions,” Clayton said. “If our customers want to see a visualization of a design concept, we can put kinematics on it and create a video to show them what it’s going to actually look like and how it’s going to help their industry.”

Since implementing DELMIA Robotics for every work cell that contains a robot, we haven’t had to move a single robot on the floor. That’s a significant time savings.

Getting the angle right

CenterLine relies on Dassault Systèmes partner Aventec for its 3DEXPERIENCE platform installation, training and upgrades. “Aventec goes above and beyond the call of duty to ensure smooth integration and migration,” Mancini added. With Aventec’s assistance, CenterLine upgraded from DELMIA V5 to the 3DEXPERIENCE platform with DELMIA Robotics, and they have reaped many benefits including a 15% productivity gain, thanks largely to the solution’s intuitive graphical user interface (GUI).

Using the GUI of DELMIA Robotics Arc Welding, CenterLine automatically generates robot arc welding tool paths based on the geometric design of the seam to be welded.

“A customer that comes to us with an arc welding project usually has certain parameters of the angles of welding,” Clayton said. “The arc trajectory function allows us to stay within those parameters. If we have to deviate, we can give the customer an exact degree and measurement of how far, and if this is still okay for their process.”

“One of the main process changes for us was bringing simulation more upfront,” Mancini said. “For an arc welding cell, we would produce all the torches on a bare product first and give that to our designers so all torches are at the optimal angle. We’ve saved at least 15-20% of the time to market for simulation and design and reduced iterations between design and tooling from six different iterations to two to three.”

Connected data provides single source of truth

Among the powerful capabilities the 3DEXPERIENCE platform brings to CenterLine is a single source of truth incorporating many different CAD data imports from customers – regardless of format – as well as legacy data from previous CAD releases.

“All the data is centrally integrated on the 3DEXPERIENCE platform. We can reuse standard items, and leverage product design and processes from previous projects,” Mancini said. “Having the data in one place allows me to be more efficient as a leader. I can focus on day-to-day operations of the simulation department rather than on managing data and products.”

The ability to integrate data from any family of robots allows CenterLine to keep up with customer requirements and to diversify into new industries, Clayton added. What’s more, DELMIA is user-friendly for creating simulation paths for users who don’t know the native language of a particular robot.

A look at the future

Understanding how important simulation is to its success, CenterLine plans to continue to drive customer value through innovation to be competitive.

“A future goal from a simulation perspective is to support the digital twin,” said Mancini. “We see this as a growing need, especially from OEMs down to the tier supplier. The idea with virtual commissioning is to have a complete model of your system, down to the safety, PLC (programmable logic controller) and robotics all interacting in the digital versus the real world. This will allow our customers to identify the systemic impact of engineering changes up front.”

“Dassault Systèmes solutions have really helped us when designing pieces of equipment to simulate the assembly in a virtual setting and really anticipate any type of problems that we could run into when selling the equipment and programming the robots,” said Levesque. “It really gives us a leg up before we put the steel to the floor.”

Focus on CenterLineLimited

CenterLine (Windsor) Limited is a family owned Canadian company that builds custom automated welding and assembly lines as well as standard brand products for fastener welding, resistance welding (steel, high strength steel, hot-stamped steel, and aluminum), metal joining, metal forming and metal coating applications.

Revenue: Privately held

Headquarters: Windsor, Ontario, Canada

For more information www.cntrline.com

Focus on Aventec

Aventec Inc. is a Dassault Systèmes Value Solutions Gold Partner, based in Markham, Ontario, Canada, whose technologies and professional services enable engineering and manufacturing companies to improve their competitiveness, productivity and profi tability. With deep expertise in the 3DEXPERIENCE platform, Aventec provides complete, integrated solutions that reduce customers’ design time from months to weeks.

For more information: www.aventec.com