Bureau Veritas

As part of its digital transformation initiative, Bureau Veritas adopted Dassault Systèmes’ 3DEXPERIENCE platform and its Designed For Sea industry solution experience for structural design, review, and collaboration.

Making the world a safer place

The products we use, the buildings in which we work, the vehicles we move around in, and the food we eat are governed by standards and regulations to make them safe for humans and the environment. Ensuring the rules are respected is the job of independent firms such as Bureau Veritas (BV). Founded in 1828, the company has grown into a world-leader in testing, inspection and certification services whose mission is nothing less than to make the world a safer place.

Bureau Veritas addresses marine & offshore as well as seven other global businesses such as industry, construction, commodities, consumer products, government services and international trade, certification, and in-service inspection and verification. “Our key values are high ethical standards, independence, impartiality, and safety,” said Philippe Donche-Gay, President Marine & Offshore division at Bureau Veritas. “We are part of a very large group comprising 1,400 offices with laboratories in 140 countries. Every office can leverage investments in innovation and technology made by the group, which gives us a competitive advantage over other classification companies,” Donche-Gay said.

Embracing digital transformation

Digital is driving changes in organizations and opening up new opportunities. As part of its growth strategy, Bureau Veritas leverages digitization to increase efficiency, expand its renowned responsiveness, and create added value for its clients. “Digital transformation is a major initiative across the BV group,” Donche-Gay said. “In this regard, our strategic partnership with Dassault Systèmes is key”.

Every industry, in one way or another, faces digital transformation, and the extremely cyclical nature of marine and offshore economics makes this sector ripe to harvest the benefits of digitization. “Digital is relatively new but is progressing fast in the shipping industry,” Donche-Gay said. “The world we live in is data-driven and the marine and offshore industry is no exception. Data is everywhere. The container ship segment is perhaps the most advanced in terms of understanding how to harness and manage the massive amounts of data generated by modern technology. The larger companies are implementing end-to-end traceability of containers. There are more and more sensors onboard vessels, which will enable much more condition-based monitoring and predictive maintenance,” Donche-Gay added.

Digitization also impacts the way Bureau Veritas ensures compliance of its customers. “Information like sea state modelling (condition of the water with respect to wind waves and swell) and casualty reports are essential to building risk models, which allow us to assess, validate, and certify new designs. Moreover, for our surveyors in the field, we have developed new applications that run on hand-held devices to keep them updated in real time. This helps them improve the quality of their response to customers. Features like checklists, news and alerts when inspections are due, all help our surveyors deal with a growing volume of information,” Donche-Gay said.

BV’s Marine & Offshore division is leading the group’s digital transformation strategy. The company adopted the 3DEXPERIENCE® platform as its collaborative platform connecting Bureau Veritas with its ecosystem of clients and their contractors and offering an enhanced user experience for improving efficiency, rapidity, quality and safety. “We selected Dassault Systèmes’ 3DEXPERIENCE platform to drive a digital transformation of our services to our customers,” Donche-Gay said

Technological innovation is essential in the marine & offshore business. Adopting the 3DEXPERIENCE platform is a key enabler because we will have to approve an increasing number of innovative designs and we need the productivity brought by this platform to satisfy customer demand.

Greener and safer ships

Bureau Veritas’ marine and offshore customers are ship designers, shipyards, ship owners, offshore operators and equipment manufacturers. All have different needs such as ensuring ships comply with local and international navigability, safety and environmental standards, reducing maintenance costs, obtaining a certification or ensuring optimal operational performance and reliability of a vessel or piece of equipment.

Digital technologies help classification societies address the opportunities linked to all these needs. “A major trend is environmental sustainability and energy efficiency,” Donche-Gay said. “Ship owners will have to comply with new environmental regulations to address areas such as ballast water management or emissions controls – whether they are CO2, SOx or NOx.”

Passenger and crew safety is another concern for ship owners. “We need to factor safety into our designs,” Donche-Gay said. “By virtually simulating an evacuation procedure in an emergency situation, we can pinpoint problem areas that can be eliminated by making changes to the design before submitting the plans to the shipyard.”

“We are also beginning to see a transformation in how the ship construction segment approaches data, notably by integrating tools into a common collaborative platform, which helps to ensure more end-to-end productivity from design to manufacturing,” he said.

To help its customers meet all these challenges, the 3D modeling initiative, based on Dassault Systèmes’ 3DEXPERIENCE platform and its Designed For Sea industry solution experience, launched as part of Bureau Veritas’ digital transformation effort, plays a strong role. “Technological innovation is essential in the marine & offshore business,” Donche-Gay said. “Adopting the 3DEXPERIENCE platform is a key enabler because we will have to approve an increasing number of innovative designs and we need the productivity brought by this platform to satisfy customer demand.”

“Our customers value our technical expertise and responsiveness. Both are essential when a ship, for example, needs to be declared seaworthy within a short timeframe to minimize loss of revenue,” Donche-Gay said. “The range and complexity of regulations have increased, especially those related to the environment. Our role, as a classification society, is to help our customers comply with these regulations and to help them improve design efficiency for better fuel consumption,” Donche-Gay said. “Our expertise is reinforced by tools such as the 3DEXPERIENCE platform as well as the internal processes we rely on to improve our service delivery.”

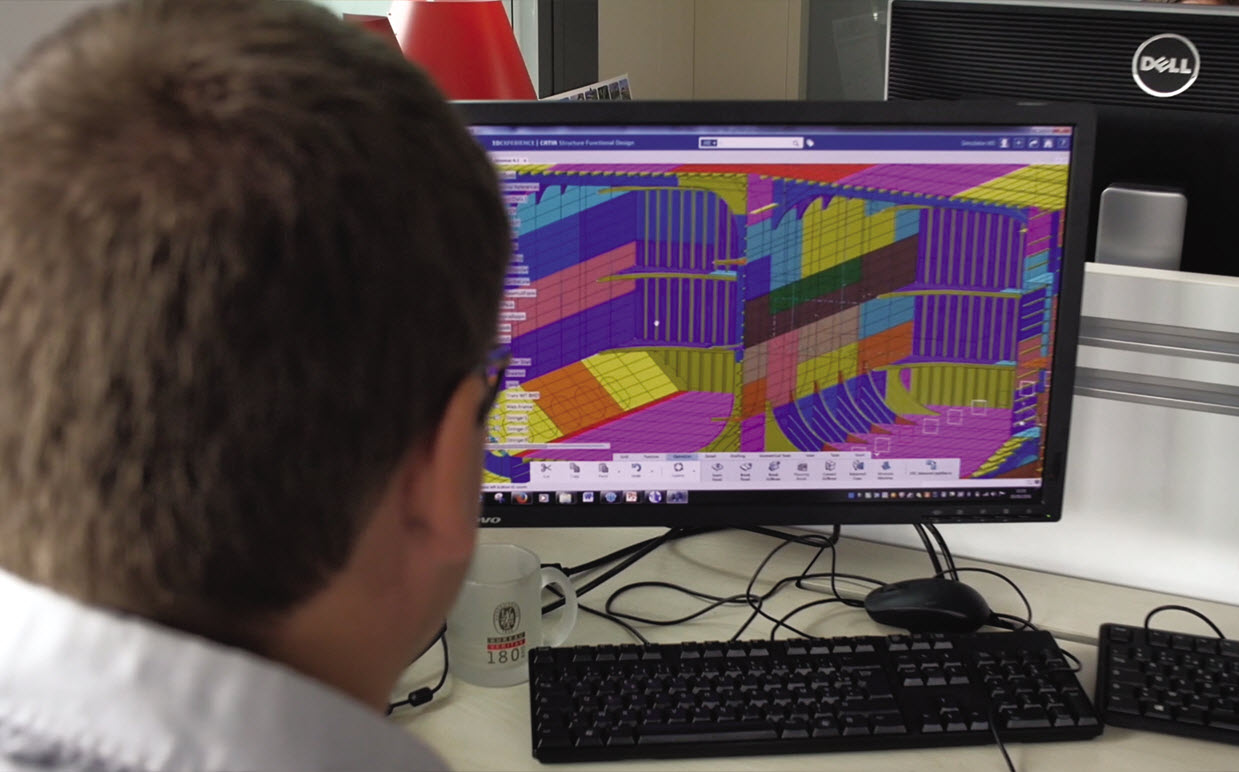

Bureau Veritas uses a detailed 3D model as the basis for all its analysis and inspection activities. “Dassault Systèmes’ 3DEXPERIENCE platform and Designed For Sea offer us a robust and integrated environment in which we can build a single digital representation of each vessel that everyone can share to perform various types of calculations,” Jean Francois Segrétain, Marine Technical Director at Bureau Veritas said. “Having a common geometrical model to perform structural verification, stability calculation and corrosion follow-up is a major improvement,” Segrétain said.

Other improvements also include enhanced collaboration and more efficient project management. “Since maritime design projects are complex, requiring the participation of globally-dispersed teams, the 3DEXPERIENCE platform’s collaborative applications help make communication between the different stakeholders smooth and efficient,” he added. “It also ensures sustainability of the project over time. Inspection information is capitalized in the 3DEXPERIENCE platform throughout the vessel’s lifetime, safeguarding against loss of know-how,” Segrétain said.

Enhanced design quality and productivity

Bureau Veritas deployed the 3DEXPERIENCE platform in all of its design review offices around the world. Dassault Systèmes Industry Services helped with implementation and training. “They tailored the solution to our needs and provided quick support whenever we had questions,” Jean-François Segrétain said. ”Surveyors from 18 of our local approval offices have been trained to use Designed For Sea to perform structural and weight analysis.”

The rapid adoption of Designed For Sea has helped Bureau Veritas dramatically improve quality and productivity. “Experienced structural engineers and stability specialists in charge of the design review activity have improved their productivity by 20% enabling them to dedicate more time guiding ship designers and verifying their work,” Segrétain said. “The associative modeling and automatic meshing capabilities have allowed us to reduce the time required to model and mesh a ship from about two months to three weeks and the time to perform hull studies by 40%,” he added.

Designs are studied by ship designers and shipyards so a key challenge is to have smooth interaction between the different stakeholders. “Some of our customers provide us with 3D models, in which case, the system automatically generates the finite element model for analysis. On the other hand, if a customer only has paper plans, our designers create the 3D model with Designed For Seabefore proceeding with analysis. Here, we use templates containing ready-to-reuse structural elements to automate and accelerate the design process,” Segrétain explained.

“The new Common Structural Rules imposed by the International Association of Classification Societies that went into effect in July 2015 to improve the safety and reliability of ship structures require to perform finite element strength assessment for the entire cargo hold region,” Segrétain said. “The geometry here is complex and takes a long time to model using traditional techniques. For our designers, this represents over two to three times more work than before. By using Designed For Sea, we have been able to neutralize this time increase.”

Enhanced early-stage collaboration with customers

Founded in 1865, Shanghai-based Jiangnan Shipyard is China’s oldest shipyard and a longtime customer of Bureau Veritas. “As we both use the 3DEXPERIENCE platform, we can easily provide Bureau Veritas with a digital ship model created using Designed For Sea so that its experts can verify the integrity and compliance of our designs,” Hu-Keyi, technical director at Jiangnan Shipyard said. “Verifications in the very early stage allow us to ensure compliance with international norms and enable us to optimize our designs, for example, by reducing steel weight. We can also create detailed build instructions for the shipyard, which help save time during the construction phase because our designs are right the first time. And we continue to use the model throughout the ship’s lifetime,” Hu-Keyi said.

A pilot project with the 3DEXPERIENCE platform was conducted by Bureau Veritas and Jiangnan Shipyard on a handysize LPG carrier to ensure its compliance to the new International code for the construction and equipment of ships carrying liquefied gases in bulk (IGC code). Now, this collaboration has been extended to other sophisticated vessels including very large passenger ships. “We need powerful tools like Designed For Sea to model these sophisticated vessels. We also cooperate with Bureau Veritas to optimize the designs of our LNG Floating Storage and Regasification Unit (LNG FSRU),” Hu-Keyi said.

Addressing marine & offshore needs for the future

Philippe Donche-Gay believes the 3DEXPERIENCE platform will help Bureau Veritas address future needs. “Opening new arctic routes and the impact this can have on vessels, as well as developing new lines of business like transporting energy all require a new generation of vessels with many technological improvements that need to be understood, addressed, and certified. We need the productivity improvements delivered by the 3DEXPERIENCE platform to successfully analyze a large number of innovative designs within the timeframe demanded by our customers. And having a single digital representation for all types of analysis such as structural calculations, stability analysis and thickness measurements to follow up on corrosion and improve efficiency,” he said.

The next important challenge for Bureau Veritas is to have a new generation solution for asset integrity management in the offshore industry. “The offshore market is experiencing a slowdown and will probably take more time to rebound,” Donche-Gay said. “With fewer platforms being built, the existing ones will stay in service longer. This triggers a need to develop new tools and services to ensure effective asset integrity management of these platforms throughout their lifecycle. We are currently working with Dassault Systèmes to develop a new generation of asset integrity management tools, which we expect to implement soon.”

“We recognize that digital transformation will be an on-going and evolving effort and that it is essential to create strong technological partnerships to stay on top of the latest innovations. In this regard, the strategic partnership with Dassault Systèmes is key,” Donche-Gay concluded.

Focus on Bureau Veritas

World-leading testing, inspection and certification company.

Products: services to help companies fulfill their quality, safety, environmental protection and social responsibility obligations

Employees: 69,000

Revenue: 4.55 billion Euros (2016)

Headquarters: Neuilly-sur-Seine, France

For more information www.bureauveritas.com