Bozankaya

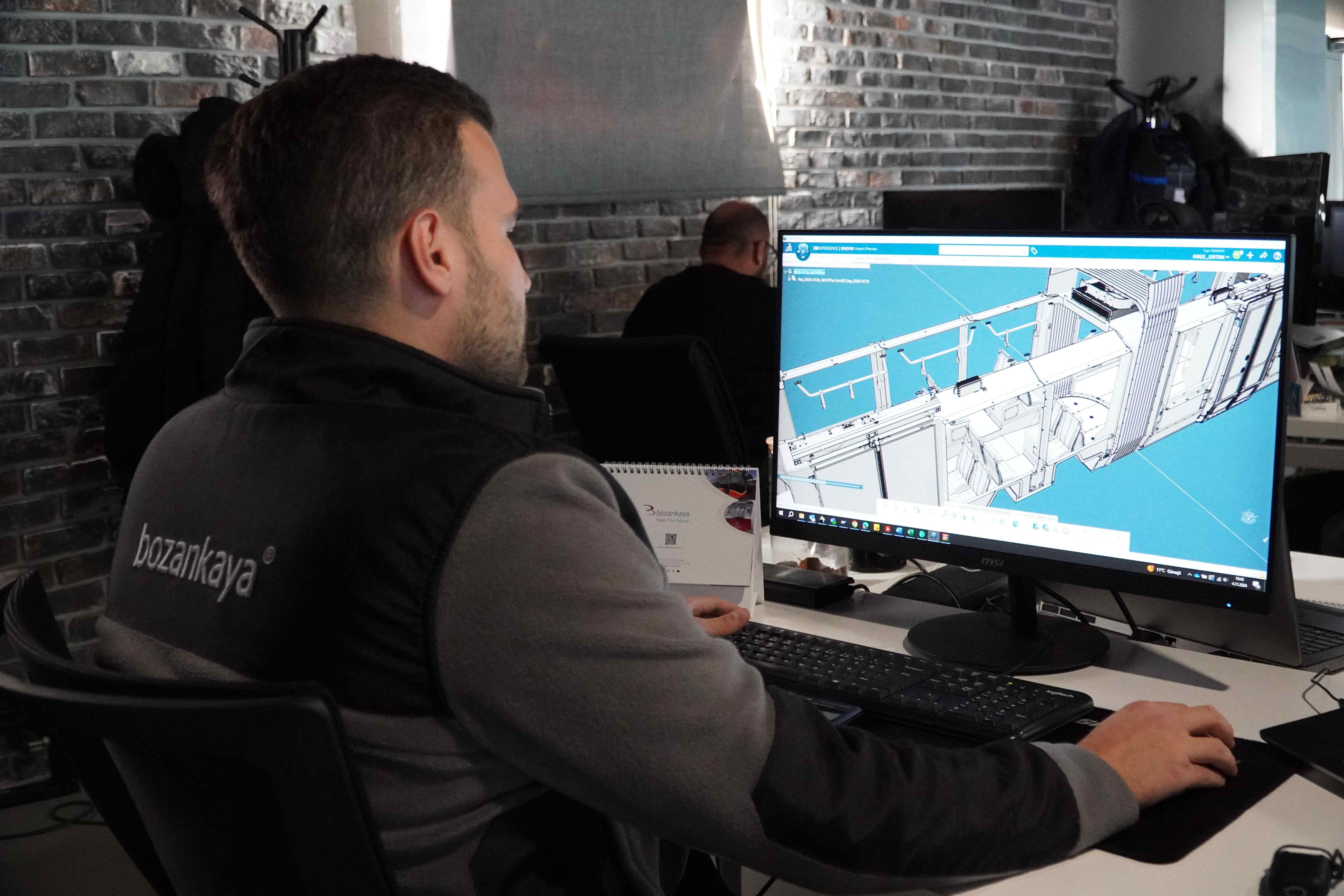

Sustainable urban mobility solutions manufacturer Bozankaya implemented Dassault Systèmes’ 3DEXPERIENCE platform to establish a single, collaborative environment. The Innovative Modules and Technologies industry solution experience provided specific processes for improved engineering efficiency, ensuring greater accuracy in production and reducing errors.

At the forefront of sustainable urban mobility

City administrators in Bangkok (Thailand), Naples (Italy), Belgrade (Serbia) and Iași (Romania) have all taken a common step to improve sustainability: transforming their public transportation networks with vehicles from Turkey-based company Bozankaya.

Bozankaya develops and manufactures environmentally friendly transport solutions. Its vehicles include Turkey’s first domestic electric bus, the country’s first driverless metro train and a 33-meter long low-floor tram that boasts a modular construction for easy repair. It has also produced the world’s first partial catenary operated battery-powered trolleybus that has unlimited range thanks to its ability to charge on the go. Exclusively dedicated to the Turkish city of Şanlıurfa, this trolleybus was recognized by FAST Company Turkey magazine, who listed Bozankaya as one of the country’s 50 most innovative companies in 2023.

To continue to be a pioneer in its industry and help even more cities worldwide transform their public transportation networks, Bozankaya has chosen to invest in an industry-leading technology solution: Dassault Systèmes’ solutions.

Our vision is to shape the future of mobility, and we can only achieve this with the right technology solutions. With Dassault Systèmes’ best-in-class solutions, we have created an end-to-end digital environment that enables us to design and produce innovative and competitive transportation solutions quickly and accurately.

Solution

After seeking advice from local partner Cadem Digital, Bozankaya was convinced that Dassault Systèmes’ 3DEXPERIENCE platform, including CATIA for design and ENOVIA for product data management, precisely matched its requirements. By leveraging POWER’BY, it could also continue to utilize its existing CATIA V5 design files.

Cadem began by analyzing Bozankaya’s processes and building a test implementation. At the same time, a number of 3DEXPERIENCE platform ‘super users’ were selected and received adaptation training over two to three days. They were then tasked to share their learning experience and train their respective teams.

The partner is now migrating legacy data to the platform. Once this is complete, all Bozankaya teams will be able to leverage the full capabilities of CATIA on the 3DEXPERIENCE platform while protecting its existing designs. Cadem will then begin rolling out ENOVIA for product data management.

Challenge

Prior to its decision to implement the 3DEXPERIENCE platform, Bozankaya was using CATIA V5 for design. Separate engineering teams were spread across different sites and worked independently using a file-based system. As a result, engineers had little idea whether they were accessing the latest design files and poor visibility into the status of a project. Work was often duplicated and time was wasted searching for information or waiting for assembly files to load. Preparing an accurate bill of materials (BOM) was particularly difficult, since it relied on manual data entry.

Recognizing that its current way of working was resulting in unnecessary delays and hampering innovation, Bozankaya realized it needed a single, unified software environment that could help it connect its design teams, facilitate real-time collaboration and unleash the benefits of concurrent engineering – the ability for all stakeholders to work on the same engineering data to accelerate the journey from design to manufacture.

Benefits

Bozankaya will have a single integrated environment in which all teams spanning multiple disciplines can collaborate on a single source of truth. Engineers will be able to manage the entire digital mockup of their vehicles through a unique interface, with the confidence that they are working on the latest version.

Using POWER’BY, engineers will be able to work with historical data from CATIA V5 as well as new data created in the 3DEXPERIENCE platform. Opening and working on large assemblies will be fast and efficient.

Once ENOVIA is rolled out, changes to engineering data will automatically be updated in the engineering BOM, ensuring greater accuracy in production by removing manual, error-prone processes.

With an end-to-end digital environment covering all processes from design to manufacturing, Bozankaya expects to shorten the time to delivery. This will result in a far more efficient operation, as well as reduced costs and increased customer satisfaction.

Discover more about the Innovative Modules & Technologies industry solution experience.

Focus on Bozankaya

Founded in Germany in 1989 before rapidly expanding into Turkey, Bozankaya has earnt itself a robust track record as an innovator in the development and manufacture of environmentally friendly urban public transport vehicles including trams, buses and high-speed trains. Over the past 30 years, the company has grown from 20 to 1,000 employees and has established a 100,000-square-meter R&D Center in Ankara. For more information: https://www.bozankaya.com.tr

Focus on Cadem Digital

Operating in digital transformation since 1998, Cadem Digital offers PLM and 3DEXPERIENCE platform solutions to provide its customers with improved speed and productivity across the full product development lifecycle. It provides innovative, integrated technologies in industrial manufacturing processes primarily for the automotive industry along with aviation, defense and machinery. Cadem Digital is a reliable, experienced and innovative solution partner in the digital transformation journey of brands in the process of creating their future, empowered by its experience and expertise in digitalization, technology, education and innovation in the industry.