Boom Supersonic

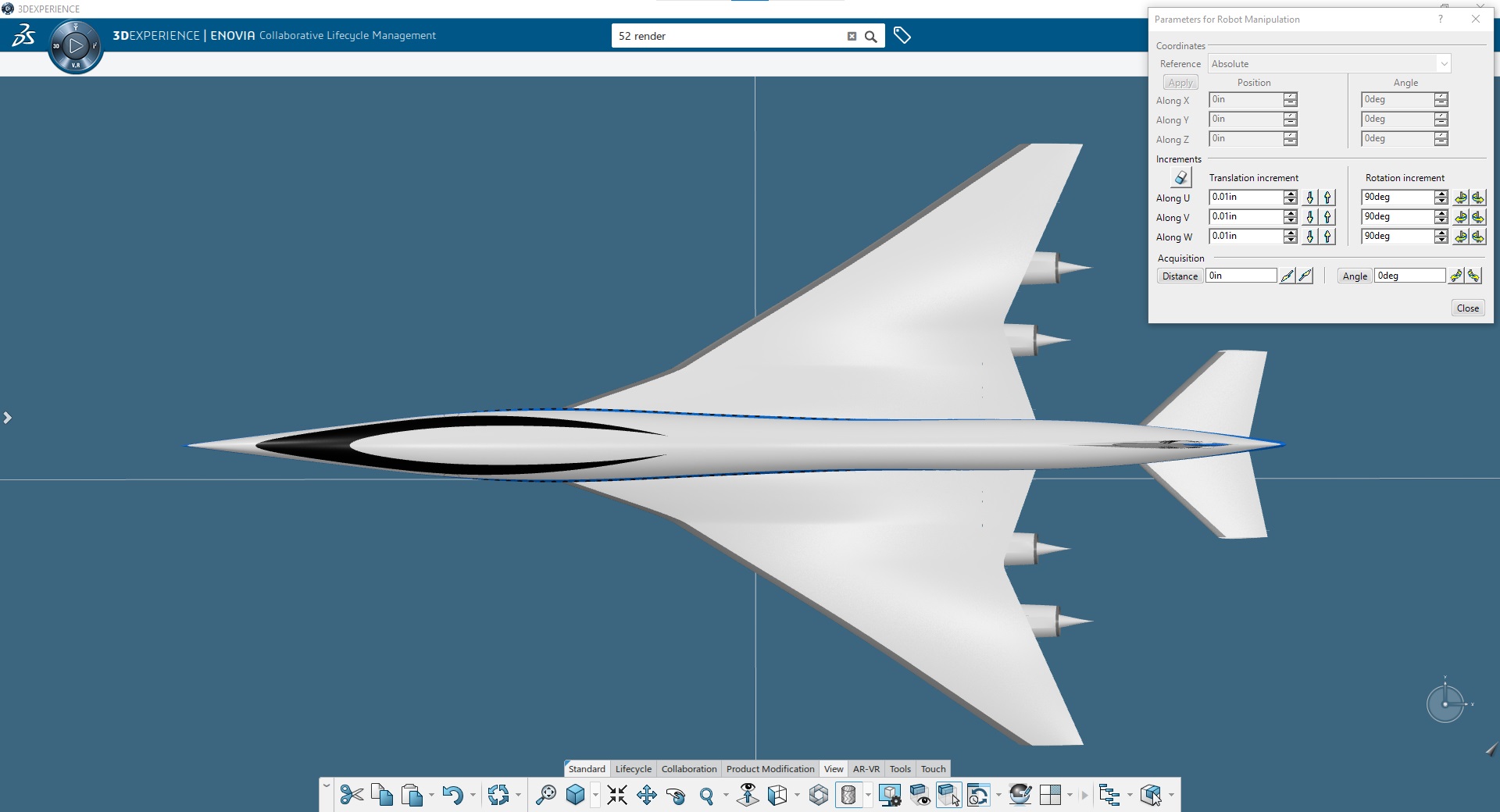

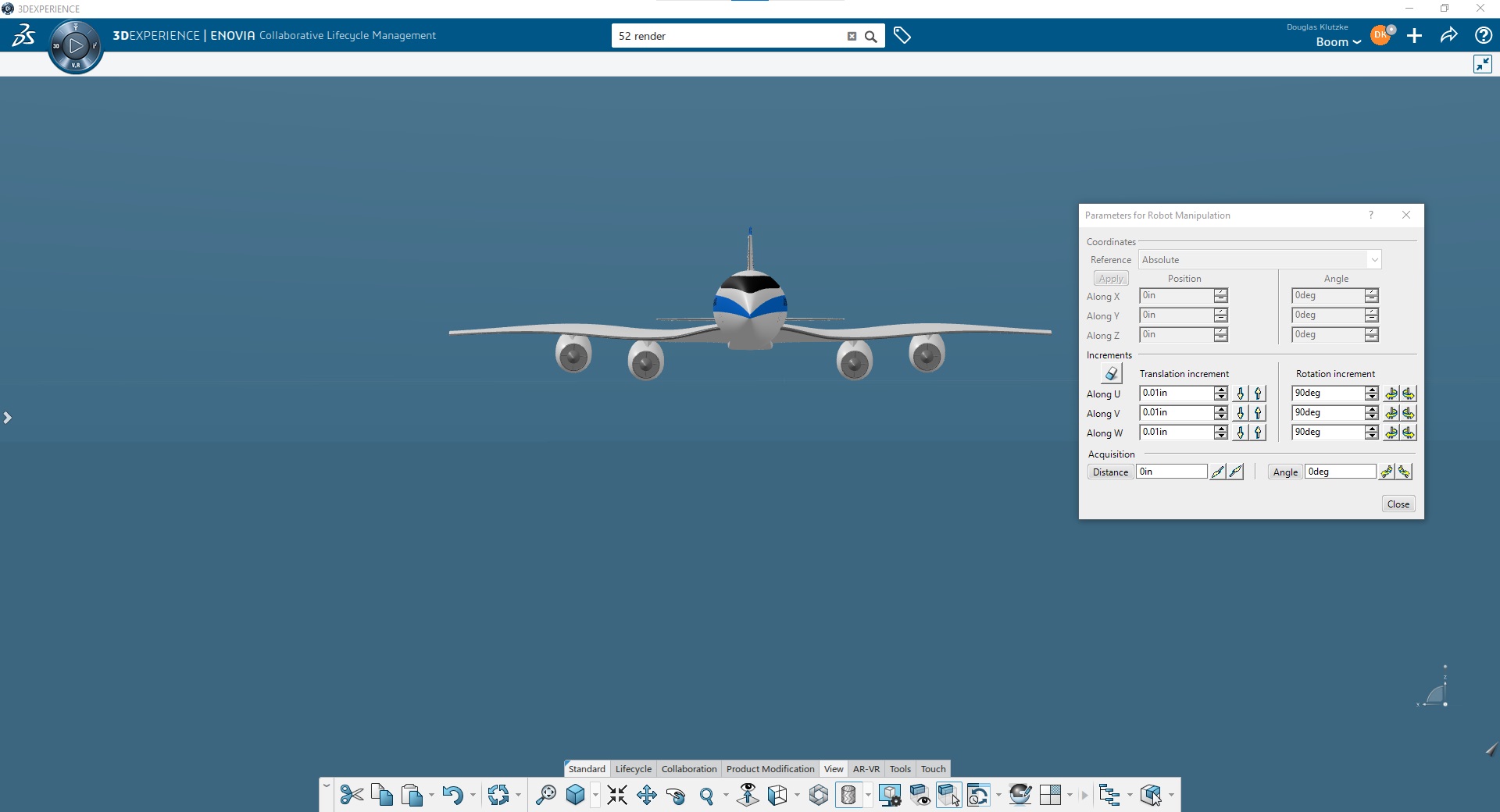

Boom Supersonic is designing and manufacturing Overture, the world’s fastest airliner optimized for speed, safety and sustainability. The company chose the industry experience solutions Cleared to Operate, Co-Design to Target, Program Excellence, and Winning Concept. The 3DEXPERIENCE platform acts as a collaborative environment in which true parametric modeling takes place at a system level.

Revolutionizing long-distance journeys with supersonic travel

Imagine traveling from New York to Rome in under five hours, compared to eight hours today. Flying at up to twice the speed of today’s passenger jets, Overture transforms multi-day business trips into single-day hops – unlocking new destinations and unique travel concepts.

This is the vision of Colorado-based aviation company Boom Supersonic who is looking to make supersonic travel a reality by the end of the decade.

“We believe in a future in which more people can go more places more often,” said Blake Scholl, founder and CEO of Boom Supersonic. “To do that we're going to make the planet dramatically more accessible by building flights that are not just faster but also more affordable, more convenient, and dramatically more sustainable.”

This is being accomplished with Overture, the world’s only supersonic airliner in development. Overture is designed to carry 64 to 80 passengers at a speed of Mach 1.7, twice as fast as current commercial aircraft. What’s more, Overture is capable of operating on 100% sustainable aviation fuel (SAF) – enabling truly net zero carbon operation. Boom will power Overture’s flight test program using SAF that was secured thanks to agreements with partners AIR COMPANY and Dimensional Energy.

“We want to completely remove sustainability as a barrier to travel,” said Scholl. “So we challenged ourselves to find a better way and Overture is not just going to be the fastest airliner but also the most sustainable – designed from the ground up to run on 100% sustainable aviation fuel."

As a company that’s achieved carbon neutrality and plans to reach net zero carbon by 2025 and net-zero greenhouse gas emissions by 2040, Boom takes sustainability seriously. The company believes any conversation about the future of travel must focus on sustainability. It intends to go beyond its own goals to create impact at scale, mobilizing its value chain, collaborating with stakeholders across the global travel ecosystem, and leading advocacy efforts to advance sustainable travel.

The path to developing complex aviation systems

Developing an aircraft like Overture is not straightforward. It is described as one of the most complicated safety-critical machines in development. Boom is collaborating with input from its network of global top-tier suppliers such as Aciturri, Aernnova, Collins Aerospace, Eaton, Leonardo, Latecoere, and Safran Landing Systems, all of which bring decades of technical engineering capability and deep experience in state-of-the-art composite materials, aerostructures components, and manufacturing.

Connecting these suppliers and disciplines is a significant challenge – especially in an industry that is often held back by monolithic systems hampering agility and innovation. Boom is focused on being faster, better, and more efficient than companies that are encumbered by legacy systems and the associated development inefficiencies that have plagued the industry for the last couple of decades.

“What we're doing is really complex,” Scholl said. “We're building one of the most complex, safety critical machines ever created, and doing that from the ground up as a new company.

Boom needed a technology platform that could facilitate internal and external collaboration; deliver the environment and tools needed to efficiently collaborate with its value network around engineering data; and integrate 3D design with aircraft requirements, virtual modeling, and MBSE development and analysis. One that could scale with the company as it moves from design into production, enabling it to meet all its major milestones to manufacture and certify Overture.

Dassault Systèmes’ 3DEXPERIENCE platform, including CATIA for 3D modeling and ENOVIA for product data management, fits the bill. Boom believes the 3DEXPERIENCE platform promises to streamline collaboration throughout its value network and eliminate file-based data storage, which ensures real-time digital continuity. The 3DEXPERIENCE platform offers Boom true parametric modeling capabilities at a system level.

“We're excited to be using the 3DEXPERIENCE platform because it allows not just our own engineers to work on the airplane but also brings our suppliers and our design partners into that same platform so that everyone's working on the same model of the airplane,” Scholl said. “Then, when we go to build the airplane, we know everything's going to fit correctly for the first time and be optimized across all the systems.”

Boom turned to Dassault Systèmes’ technology partner, Inceptra, for help with implementation, leveraging their experience in the aerospace industry. Boom collaborated with Inceptra to streamline business processes and define a custom path for implementation. The Inceptra team advised Boom on documentation for certification, requirements integration, and product lifecycle management (PLM) structure.

Collaborating for success

For Boom’s engineers, adopting the 3DEXPERIENCE platform was quick and easy, and immediate benefits were realized. One of the biggest benefits to Boom is improved collaboration by combining processes and data into a single virtual environment. All Boom engineers can now work on the same live data set, no matter where they are located. The company’s remote users can utilize a VPN connection, allowing design to be supported from anywhere in the world.

Moreover, and just as critical, these benefits are not just felt by the internal team. The ability to model concurrently with suppliers allows Boom’s team to evaluate design decisions from different perspectives and enables the best path to drive the design.

This external collaboration happens in a carefully considered and secure way. Boom, like all aerospace companies, is concerned about protecting its intellectual property (IP) when exporting certain files to external stakeholders. Advised by Inceptra, Boom used the 3DEXPERIENCE platform to segment data to interface suppliers into the product development without exposing the full aircraft IP. Boom also can create roles to control access to company information protected by the International Traffic in Arms Regulations (ITAR).

Embracing the 3DEXPERIENCE platform

With CATIA, Boom engineers are implementing a model-based systems engineering (MBSE) approach that captures and tracks requirements early in the process and continues throughout the entire product lifecycle.

This means Boom can design complex systems and track the aircraft’s development iterations, understanding the impact of different design decisions to a greater extent. CATIA allows for rapid CAD evaluation and reaction to changes in the aircraft design to evaluate fit, form, and functionality from one iteration to the next, while ensuring validation of design requirements.

For example, parameterized models created using SIMULIA PowerFLOW effectively update assemblies on-the-fly to the ever-evolving and improving shape of the aircraft’s Outer Mold Lines (OML). During development, parameterization allows the flight deck to instantly morph to fit within the fuselage forward section and allows the landing gear to interact with the wing-to-body fairing to influence the OML for fitting around the reserved system volume. Another example is the flight controls which can be integrated into wing and empennage outer surfaces and fed back to the computational fluid dynamics environment for validation against the aircraft control requirements.

Engineers also evaluate the ergonomic and physical aspects of the aircraft’s systems while in motion. The 3DEXPERIENCE platform’s mechanical system design modules allow Boom to check the range of motion and provide simulated forces and control laws on the developed models to see how they react with the surrounding environment.

Flagged immediately are any design limitations, which helps Boom to engineer quicker and achieve aircraft maturity sooner. As the design continues to firm up, Boom expects to see direct modeling provide concurrent validation of the aircraft at a system level.

Data control is imperative to a new aircraft development process. Once Overture is ready for production, data managed by ENOVIA will support the certification process. ENOVIA delivers product data management and PLM capabilities that will prove to the certification authorities and regulators that the system is fully controlled and ready for the requirements of a certified production environment.

Flying high in the future

Today, Overture is progressing through the development phase. Boom announced tier-one suppliers that will contribute to key systems on Overture, and, at the Paris Air Show, Boom revealed the key systems inside Overture, including avionics, flight controls, hydraulics, fuel systems and landing gear – all designed and developed for optimal performance, efficiency, and safety. Boom also broke ground on the Overture Superfactory, the site of the final assembly line, flight test and customer delivery center for Overture, in North Carolina, which should be complete by mid-2024.

To reach the finish line, Boom will look to leverage additional capabilities of the 3DEXPERIENCE platform. By integrating Boom requirements into the platform, the first step is to connect requirements to the product and understand how changes in the design process validate requirements or invalidate them, requiring further iteration. Boom is interested in continuing to explore this digital continuity with the right support in the form of licensing, training, and collaboration with Inceptra and Dassault Systèmes to bring future activities like the manufacturing line into the design process and simulate product assembly before ordering the first part.

Boom expects the 3DEXPERIENCE platform will energize the design process by rapidly bringing future iterations of Overture to the aerospace industry, cutting down on development time and cost.

“When supersonic flight first comes back, it's going to be incredibly special and people will celebrate every time they break through the sound barrier,” concludes Scholl. “What I'm really looking forward to is when that becomes ordinary.”

Discover more about the Cleared to Operate industry solution experience.

Discover more about the Co-Design to Target industry solution experience.

Discover more about the Program Excellence industry solution experience.

Discover more about the Winning Concept industry solution experience.

00:00 – 00:10

Host:

Can you share with us what’s the vision of Boom for the future of flight?

00:11 – 00:23

Blake Scholl, Founder & CEO, Boom Supersonic:

Well we believe in a future in which more people can go more places more often. And to do that we’re going to make the planet dramatically more accessible by building flights that are not just faster but also more affordable, more convenient and dramatically more sustainable.

00:24 – 00:30

Host:

I know that Boom is focusing a lot on sustainability, so it is key I think for the future of Aerospace, right?

00:31 – 00:45

Blake Scholl:

Absolutely. We want to completely remove sustainability as a barrier to travel so we challenged ourselves to find a better way and Overture is not just going to be the fastest airliner but also the most sustainable designed from the ground up to run on 100 sustainable aviation fuel.

00:46 – 00:48

Host:

What are some of the biggest challenges you’re overseeing right now?

00:49 – 01:20

Blake Scholl:

So what we’re doing is really complex. We’re building one of the most complex, safety critical machines ever created, doing that from the ground up as a new company. Let me tell you what it’s not. It’s not that passengers want this. You know, every passenger wants a faster flight, we’re seeing that airlines want it. United Airlines was the first to place a firm order for 15 Overtures. It’s not just the technology exists, we’ve demonstrated that with our prototype airplane and the Aerospace supply chain has come along so far since Concord. It’s not regulations we’re able to meet or in some cases even exceed current environmental and safety regulations.

01:21 – 01:25

Host:

So how are you leveraging digital technologies to address those challenges?

01:26 – 01:48

Blake Scholl:

That’s absolutely key to the strategy and that’s part of the reason that we’re excited to be using the 3DX platform. Because it allows not just our own engineers to work on the airplane but also to bring our suppliers and our design partners into that same platform, so that everyone’s working on the same model of the airplane. And when we go to build the airplane we know everything’s going to fit correctly for the first time and be optimized across all the systems.

01:49 – 01:51

Host:

So what can we look forward for Boom in the future?

01:52 – 02:05

Blake Scholl:

You know when supersonic flight first comes back, it’s going to be incredibly special and people will celebrate every time they break through the sound barrier. What I’m really looking forward to is when that becomes ordinary and people don’t want to be interrupted to celebrate because supersonic flight is just the norm for everybody.

02:06 – 02:09

Host:

So count me in! Looking forward to be part of the passengers in the future. Thank you so much, Blake.

02:10 – 02:14

Blake Scholl:

Thank you.

Focus on Boom Supersonic

Boom Supersonic is transforming air travel with Overture, the world’s fastest airliner, optimized for speed, safety, and sustainability. Overture will fly at twice the speed of today’s airliners and is optimized to run on 100% sustainable aviation fuel (SAF). Overture’s order book stands at 130 aircraft, including orders and pre-orders from American Airlines, United Airlines, and Japan Airlines. Boom is working with Northrop Grumman for government and defense applications of Overture. Suppliers and partners collaborating with Boom on the Overture program include Aernnova, Leonardo, Latecoere, Aciturri, Safran Landing Systems, Eaton, Collins Aerospace, and the United States Air Force.

For more information: https://boomsupersonic.com/

Focus on Inceptra

Inceptra helps engineering and manufacturing enterprises of all sizes across a variety of industries with best fit solutions to digitally design, simulate, produce, and manage their products and processes, enabling enhanced innovation and productivity. We are dedicated to Dassault Systèmes’ product portfolio, plus complementary software and internally developed PLM acceleration solutions. Inceptra’s offerings include software, support, training, and consulting services, including integration services, automation services, and industry best practices.