Avidicare

Avidicare AB, a research-based medical technology company, developed an innovative air ventilation system to reduce airborne bacteria and virus contamination by managing airflow to reduce patient and staff illnesses in hospital rooms. Computational fluid dynamics (CFD) software enables Avidicare engineers to design and optimize airflow to the minute particle level of human coughing and breathing. Simulations enable engineers to see invisible airflows and thereby help solve product issues digitally and optimize product design early in product development.

MOVING AIR TO REDUCE AIRBORNE ILLNESSES

“A jet airliner with 54 people aboard was delayed on the ground for three hours due to engine failure during a takeoff attempt. Most passengers remained on the airplane during the delay. Within 72 hours, 72 percent of the passengers became ill with symptoms of cough, fever, fatigue, headache, sore throat, and muscle aches. One passenger, the apparent index case, was ill while on the airplane, and the clinical attack rate among the others varied with the amount of time spent aboard...The airplane ventilation system was inoperative during the delay, which may account for the high attack rate.”

How do you control the effects of breathing the same air as others? Because the breath is automatic, most people, except those who exercise or meditate, do not even notice it. Air itself is invisible, which makes preventing typical airborne diseases, such as the common cold or various types of influenza, particularly difficult.

The COVID-19 pandemic brought heightened attention to the quality of indoor air. Heating, ventilation, and air conditioning (HVAC) systems faced intense scrutiny—especially within healthcare systems—along with a provocative question: Could redesigning indoor airflow prevent, or at least reduce airborne illnesses?

“Indoors, the concentration of viral particles is often higher than outdoors, where even a light wind can rapidly reduce concentrations. When indoors, ventilation mitigation strategies can help reduce viral particle concentration. The lower the concentration, the less likely viral particles can be inhaled into the lungs, potentially lowering the inhaled dose...Protective ventilation practices and interventions can reduce the airborne concentrations and reduce the overall viral dose to occupants... and ventilation system upgrades or improvements can increase the delivery of clean air and dilute potential contaminants.”

INNOVATIVE AIR VENTILATION SYSTEM

Avidicare AB is a research-based medical technology company with an innovative air ventilation system called Opragon that manages and reduces airborne bacteria and virus contamination in hospital operating rooms. The innovation was designed primarily to prevent surgical site infections (SSI) during sensitive surgeries.

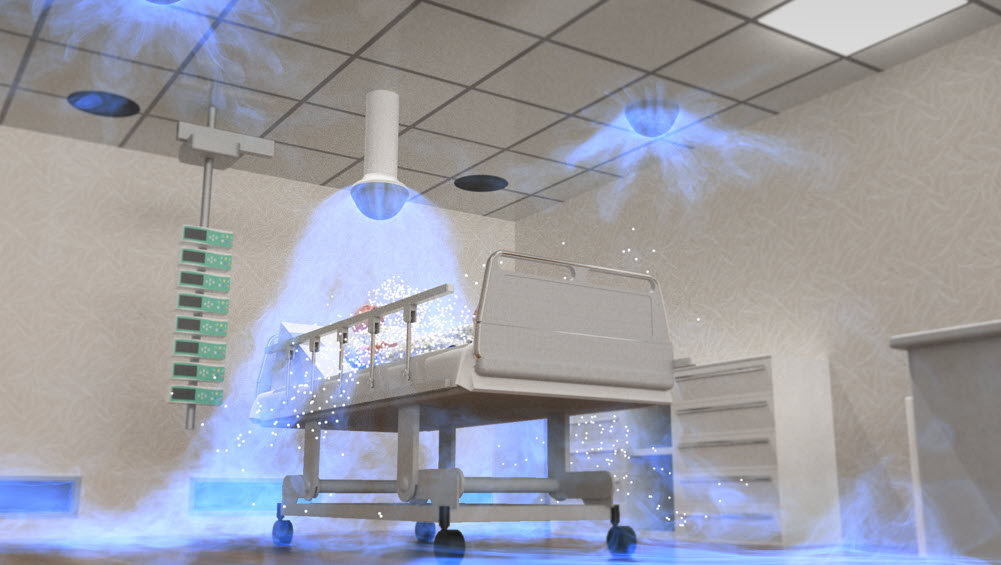

The system is based on a revolutionary combination of the classic mixed ventilation, which dilutes the number of bacteria-carrying particles in the periphery of the room, and a unidirectional flow in the middle of the room. The principle is called temperature-controlled airflow (TcAF) ventilation. With TcAF, Opragon generates a superior level of purity throughout the entire operating room, supplying slightly cooled air in a zone around the operating table, while evenly spaced external “air showers” regulate the temperature of the room.

The idea for Opragon started with cleanrooms, which are highly sterile environments. The first time the former parent company of Avidicare installed the TcAF ventilation technology in a cleanroom, the customer gave them the feedback that the incidence of sick days had decreased since the installation. Realizing that the innovative way for moving air using very little energy could have useful applications outside of cleanrooms, Avidicare soon developed the Opragon technology to build airflow innovations for operating and isolation rooms in hospitals.

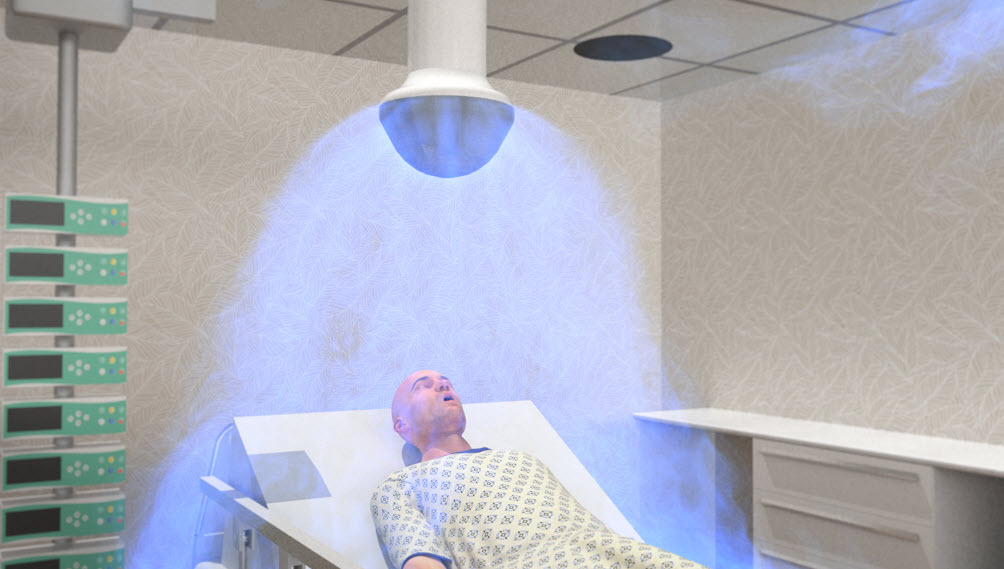

“Now we’re leveraging this technology, considering the learnings from the COVID pandemic,” says Chief Executive Officer Peter Höjerback. “We realized that we are not only protecting the patients from bacteria and infections but also protecting staff from airborne infections.” A critical physics nuance of the airflow technique is the use of cooled air. “Since cold air is heavier than warm air, it will fall down by itself,” explains Höjerback. “Much like dropping a stone, cooler air accelerates from the ceiling to the floor. That means we can use much less energy to move the air the way we want.”

The PowerFLOW product has definitely reduced our product development time since we don't need to build a system and then rebuild physically to improve it

SIMULIA’S COMPUTATIONAL FLUID DYNAMICS SIMULATION

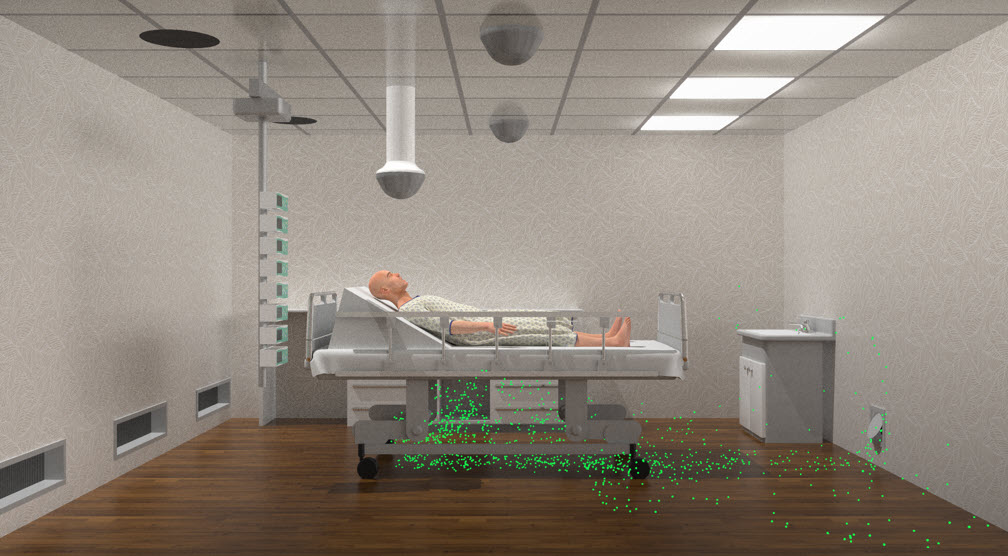

Avidicare used SIMULIA’s PowerFLOW CFD solution to begin testing a novel idea for hospital isolation rooms where the objective is to keep both the patient and the staff free from infection or illness. The PowerFLOW simulation team modeled the virtual twin of a hospital room as well as droplet nuclei, small airborne particles that are exhaled by a patient during a breath or a cough. (It is assumed that the nucleus potentially contains a virus of some kind.) PowerFLOW enabled Avidicare to virtually see where the droplets propagate in the room, on which surfaces they deposit, how they are extracted from the room and other critical behaviors.

“The PowerFLOW CFD software is an effective way for developers of HVAC solutions to be able to show what is happening in a way that people will understand,” says Höjerback. “When people see the airborne bacteria and viruses, they can all of a sudden start to evaluate different approaches and better understand how to work in a hospital room to better protect their patients and staff from these airborne threats.”

Avidicare’s airflow control products use temperature modification strategies to push infectious particles downward. The particles are then removed from the room near the floor. Still, staff can set any desired temperature for best comfort and the system automatically adapts. PowerFLOW enables simulation of not only local velocity and pressure fields but also of what happens at the particle scale, so researchers can study how the flow would develop and how it would reach an optimal and more stable condition. Seeing the particle distribution within the room is critical for testing because Avidicare’s technology keeps them at about 40 inches or less from the floor, keeping everyone in the room safer from airborne illnesses.

“The PowerFLOW product has definitely reduced our product development time since we don’t need to build a system and then rebuild physically to improve it,” says Höjerback. “We can try different designs with different air flows and the different number of outlets and optimize the product in the digital realm.” If something in the digital simulation needs improvement, the Avidicare team can make modifications before taking the time and expense to build the physical product. Höjerback continues: “PowerFLOW has been instrumental in helping us improve our airflow technology cost-effectively and efficiently.”

There are several challenges when building a system that manages invisible elements such as airflow. One is validating and optimizing system performance. Another is demonstrating product value to potential customers in a visible way, so everyone can see how the system works and why it is more effective than other HVAC approaches to reducing the risk of infections and illnesses among patients and staff. “Working with SIMULIA’s PowerFLOW team has been a mutually rewarding experience,” enthuses Höjerback. “PowerFLOW is a wonderful tool.”