ATOM CUTTING

Italian cutting machine manufacturer ATOM CUTTING is a leading global provider of innovative cutting systems for a range of industries from fashion to aerospace and uses the 3DEXPERIENCE platform on the cloud for its product development processes. With the Digital Equipment Continuity industry solution experience, ATOM can centralize all product development data and bring together different disciplines within a single environment.

Industrial cutting machines shape smart manufacturing

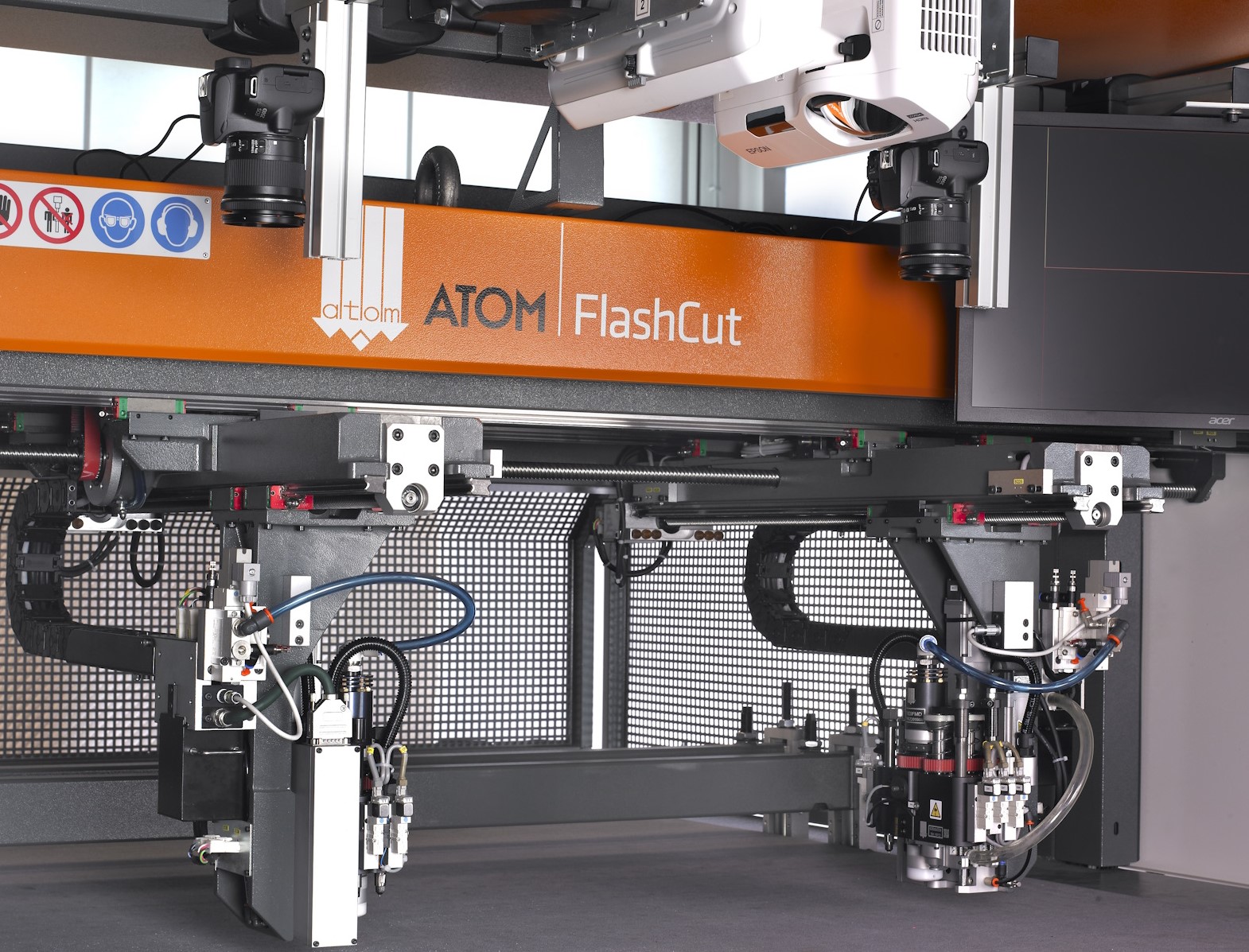

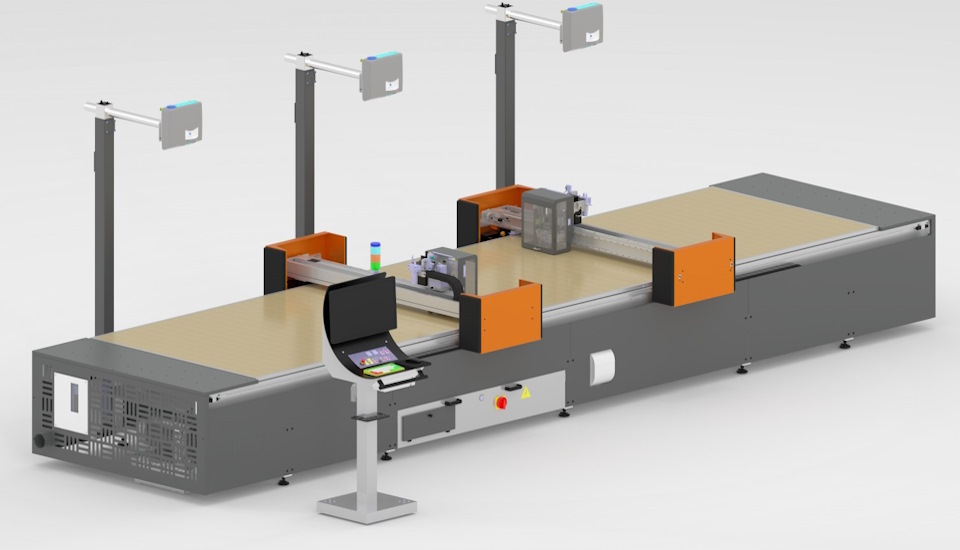

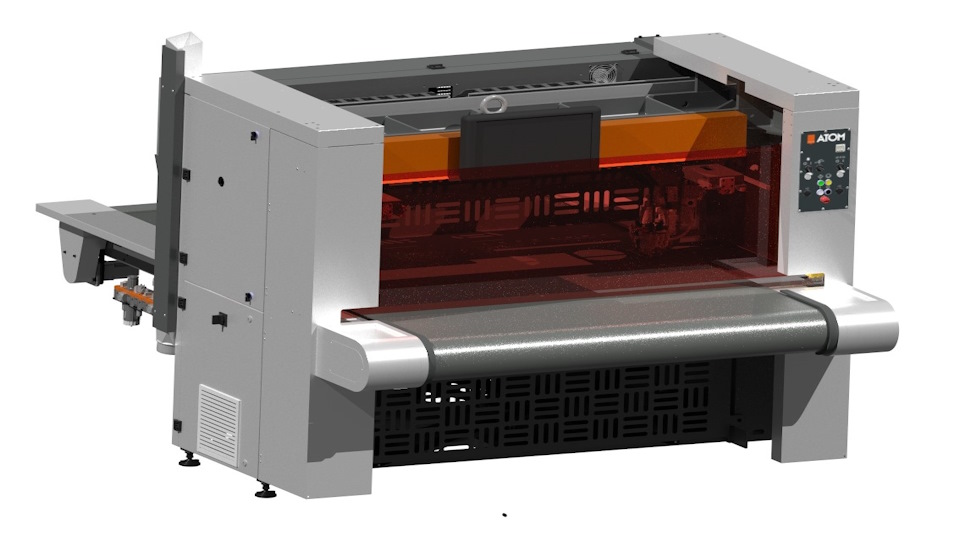

Blending precision and efficiency, ATOM CUTTING’s cutting machines continue to push the boundaries of what’s possible in smart manufacturing. Whether they’re crafting sports shoes and luxury leather handbags, cutting through multiple layers of fabric for car seats, or slicing and milling composite materials bound for space, the Italian manufacturer’s industrial cutting machines are some of the most innovative on the market. Far from the days of traditional, manual die cutting processes, ATOM CUTTING’s latest equipment integrates advanced tools and automated nesting, control and monitoring systems – setting a new standard for accuracy, output and sustainability in industries ranging from fashion to aerospace.

Among the company’s latest innovations is a cutting machine system equipped with linear motors. Compared to traditional rotary motors, linear motors operate without mechanical gears, instead relying on magnets to generate a direct linear force. This direct-drive approach is redefining what’s possible in motion control, significantly boosting acceleration and speed but also reducing the maintenance and the wear and tear to extend the overall system’s lifespan.

“Launching in the US, demand for this new type of cutting system is high, especially from industrial companies, which are always looking for ways to speed up product development, improve quality and lower maintenance costs,” said Ezio Marandola, chief technology officer at ATOM CUTTING. “Introducing new technology is how we differentiate ourselves in the market, building on our reputation for reliability, performance and cost effectiveness. We’re also renowned for our comprehensive aftersales service so our customers get the most from their investment.”

Like the rest of its product portfolio, ATOM CUTTING’s latest machine was developed using Dassault Systèmes solutions. The company made the decision to move its product lifecycle management (PLM) processes to the 3DEXPERIENCE platform and take advantage of CATIA for design and ENOVIA for project management as part of a wider vision to connect its organization and centralize all data management.

ATOM CUTTING centralizes all product development data and brings together different disciplines within a single environment – the 3DEXPERIENCE platform on the cloud.

Manufacturer breaks down data silos

ATOM CUTTING has long relied on software from Dassault Systèmes to design its machines. As its products have become even more sophisticated and complex, though, the company wanted to invest in the latest technological capabilities to support its product development and bring new levels of visibility across the business.

“Before, we used CATIA and had a separate enterprise resource planning (ERP) system for the bill of materials (BOMs), but there was no connectivity between the two and data integration was handled manually, which slowed us down” Marandola said. “As each department stored data in different systems and servers, it was also difficult finding the information we needed. To stay ahead of the competition, it was critical that we moved to a centralized environment.”

ATOM CUTTING worked with its technology partner CAD Solution Provider (CSP) to upgrade its technology. The manufacturer wanted to continue using CATIA and assessed which other Dassault Systèmes solutions would suit its specific needs. It made the decision to implement the 3DEXPERIENCE platform on the cloud as its PLM system.

“We liked the possibility of being able to securely access and share data from anywhere,” Marandola said. “The cloud-based installation also meant we wouldn’t have to buy and install additional dedicated hardware.”

Today, ATOM CUTTING relies on Dassault Systèmes’ platform to manage all product and project data. The company’s globally dispersed team benefits from a structured online environment to work together in a more streamlined way and knows it’s working with the most up-to-date designs and product data. ATOM CUTTING even uses the 3DEXPERIENCE platform on the cloud to communicate with its plant in China, which can view designs, BOMs and work instructions in the collaborative space.

“We now have robust data management,” Marandola said. “All documentation such as operator and user manuals, spare parts libraries and risk analysis is stored in the collaboration platform for every project. It’s available for everybody who needs it.”

There’s no longer a need for us to have meetings to resolve project management issues. Every project now has a clear, up-to-date roadmap so all key stakeholders can see the current status. This transparency amplifies our design power.

Platform facilitates reuse of cutting solutions

ATOM CUTTING designed its newest linear motor cutting system internally using CATIA. Introducing a new innovation like the linear motors meant that the team had to create many new parts from scratch. They also reimagined the design of the machine, modifying it to mount the new motor and refining the aesthetics in line with demand from industrial companies for modern, stylish equipment made with the highest quality materials. ATOM CUTTING exported the 3D models via the 3DEXPERIENCE platform to external suppliers, which produced specific parts including the casing.

Every time the company produces a new machine, it refers to its existing design portfolio so it can reuse parts where possible and speed up the design process to keep up with tight delivery deadlines. Before moving to the 3DEXPERIENCE platform on the cloud, it was harder for engineers to find the design data they needed, slowing them down and resulting in the creation of duplicate parts. Now that everything is stored centrally, this is no longer an issue.

“We work a lot with historical data – checking for similar parts before we create new designs,” Marandola said. “With the design library – a database of components with comprehensive descriptions – we can easily find and reuse existing designs and parts and even identify alternatives that may work better in a particular configuration. As we build up a complete view of each machine within the virtual world, it’s also much easier for us to generate all required documentation, including user manuals, and deliver a connected aftersales service, including managing maintenance and replacement parts, which companies need to get the most from their equipment and extend its lifespan.”

The backwards compatibility of Dassault Systèmes’ software meant that ATOM CUTTING didn’t have to transfer all of its legacy design data to the 3DEXPERIENCE platform. While all new projects are now managed entirely in the latest version of the platform, engineers can still access and view older projects, keeping ATOM CUTTING’s design archive intact and making sure no intellectual property is lost along the way. “We really value the ability to easily access CATIA V5 data on demand without the need to transform everything to the latest software version,” Marandola said.

An extract from ATOM's portfolio

Transparent project management

ATOM CUTTING’s engineering team is working more efficiently and collaboratively, benefiting from the 3DEXPERIENCE platform’s robust data management, which mitigates human errors, version control issues and lost information. The company also takes advantage of Dassault Systèmes’ project management features in ENOVIA. This data-driven project management solution seamlessly integrates product development data with each individual project. Any changes are instantly updated in the overall plan, so that project managers can govern and oversee progress.

“There’s no longer a need for us to have meetings to resolve project management issues,” Marandola said. “We’ve streamlined internal communication and now any issues are logged and handled by our technical office, which sorts tasks according to their priority level and assigns them to individuals with the right skillsets. We’re also building our knowledge as we’ll be able to refer back to historical examples of how we’ve solved other problems. Every project now has a clear, up-to-date roadmap so all key stakeholders can see the current status. This transparency amplifies our design power.”

ATOM CUTTING now looks forward to building on the success of its digital transformation and working with Dassault Systèmes and CSP to take advantage of more of the 3DEXPERIENCE platform’s capabilities to work even more efficiently throughout the product development lifecycle. It also hopes to bring even more transparency to customer relations and further streamline aftersales service delivery by making available even more comprehensive user manuals, spare parts documentation and service records.

“In the last two years, we’ve spent a lot of time learning to use the system,” Marandola said. “We’re already developing our machines faster and speeding up time to market. Now that we’re up and running and using more of Dassault Systèmes’ applications, we expect to work even more productively and find new ways to add value for our customers.”

Discover more about the Digital Equipment Continuity industry solution experience.

Focus on ATOM CUTTING

For over 70 years, ATOM CUTTING has been designing, developing and manufacturing cutting systems for flexible and semi-rigid materials. The international company offers state-of-the-art solutions for design, production and automation of the shoe and leather goods manufacturing process, as well as for the industrial field. Different products, one common denominator: product quality, state-of-the-art technology and an international sales and customer network.

For more information: https://atom.it/en/

Focus on Cad Solution Provider

CSP is a subsidiary of Cadland Group and distributes Dassault Systèmes software throughout Italy. The company is a Dassault Systèmes PLM Certified Reseller and Certified Education Partner, delivering high quality training on the Dassault Systèmes software portfolio. With its extensive expertise, CSP guarantees its customers the highest quality services and products.

For more information: https://www.cadsolutionprovider.it/